Inlaid type floor sheet having polyvinyl chloride chip and the method of manufacturing thereof

Inactive Publication Date: 2014-07-31

LG HAUSYS LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

The inlaid type floor sheet with polyvinyl chloride chip and the method of manufacturing it have a reinforcing layer that makes it stronger and more durable. This results in a more stable and balanced floor sheet that also adheres better to the construction floor.

Problems solved by technology

However, its dimensional stability is low, and since the polyvinyl chloride chip layer 21 formed of a hard material is directly contacted with the construction floor, it is difficult to handle and construct it.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

embodiment

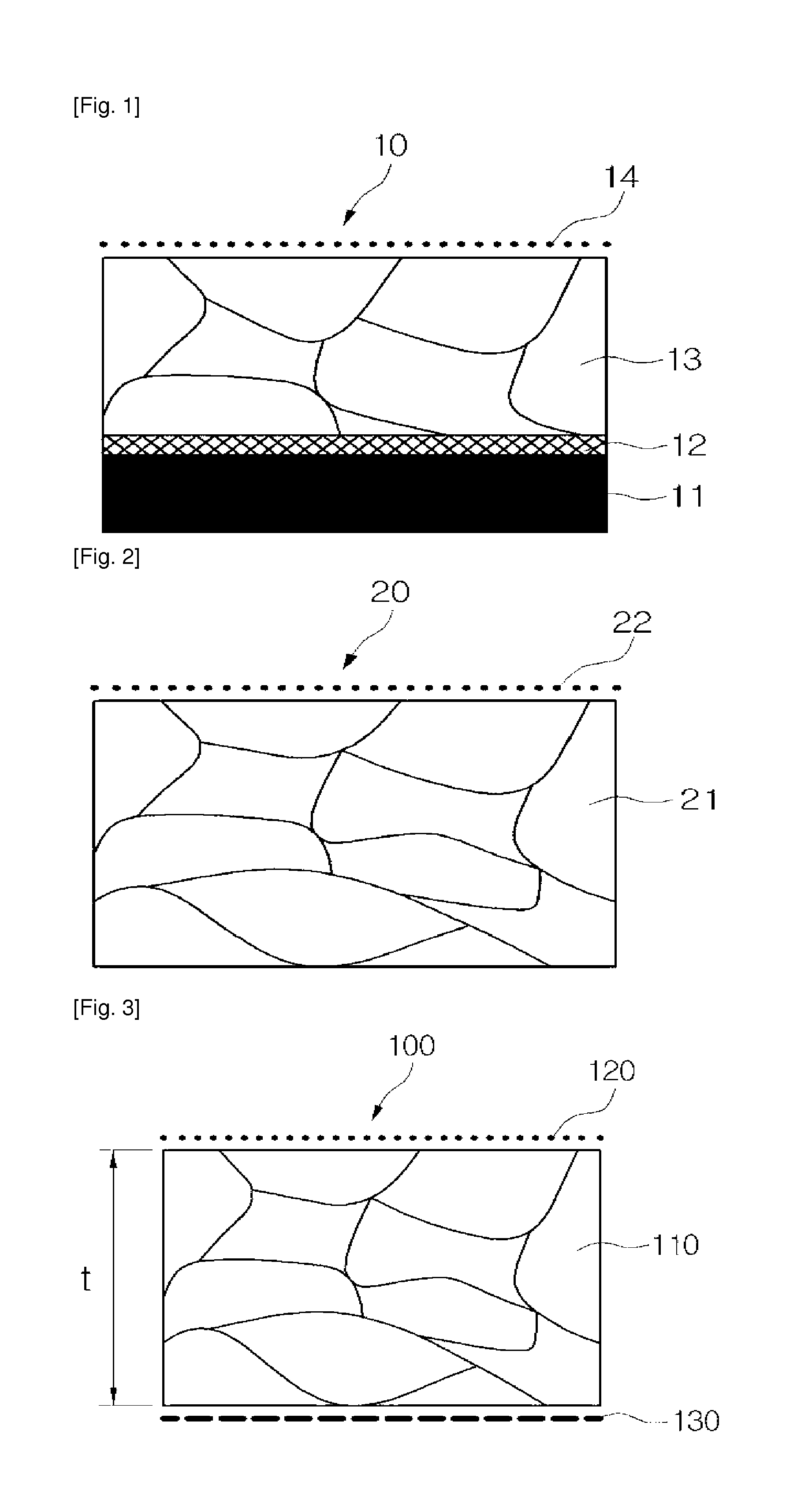

[0042]The dimensional stability and the adhesive strength were measured using the floor sheet 100 in which the UV paint layer 120, the inlaid chip layer 110 and the dimensionally reinforcing layer 130 were stacked in turn.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Login to View More

Abstract

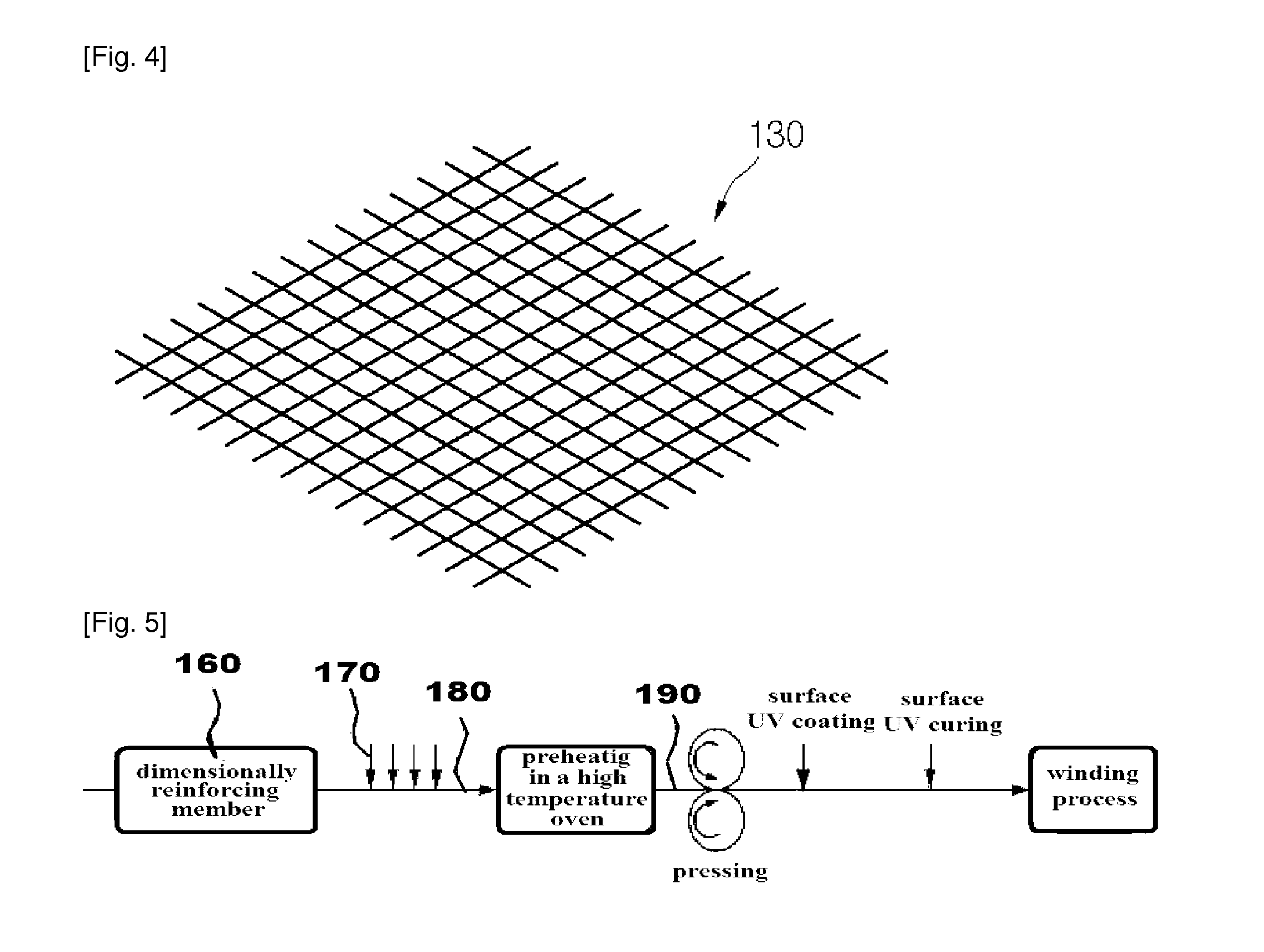

Disclosed is a inlaid type floor sheet having polyvinyl chloride chip and a method of manufacturing thereof. The in-laid type floor sheet having polyvinyl chloride (PVC) chip, includes an inlaid chip layer in which polyvinyl chloride is formed into chips; a UV paint layer which is coated on the inlaid chip layer; and a dimensionally reinforcing layer which is formed of a fabric and pressed on a lower surface of the inlaid chip layer at high temperature. According to the present invention, since the plain weave type dimensionally reinforcing layer is provided at the lower side of the inlaid type floor sheet having polyvinyl chloride chip, it is possible to improve the durability, realize the dimensional stability and balance of the product and increase the adhesive force with the construction floor.

Description

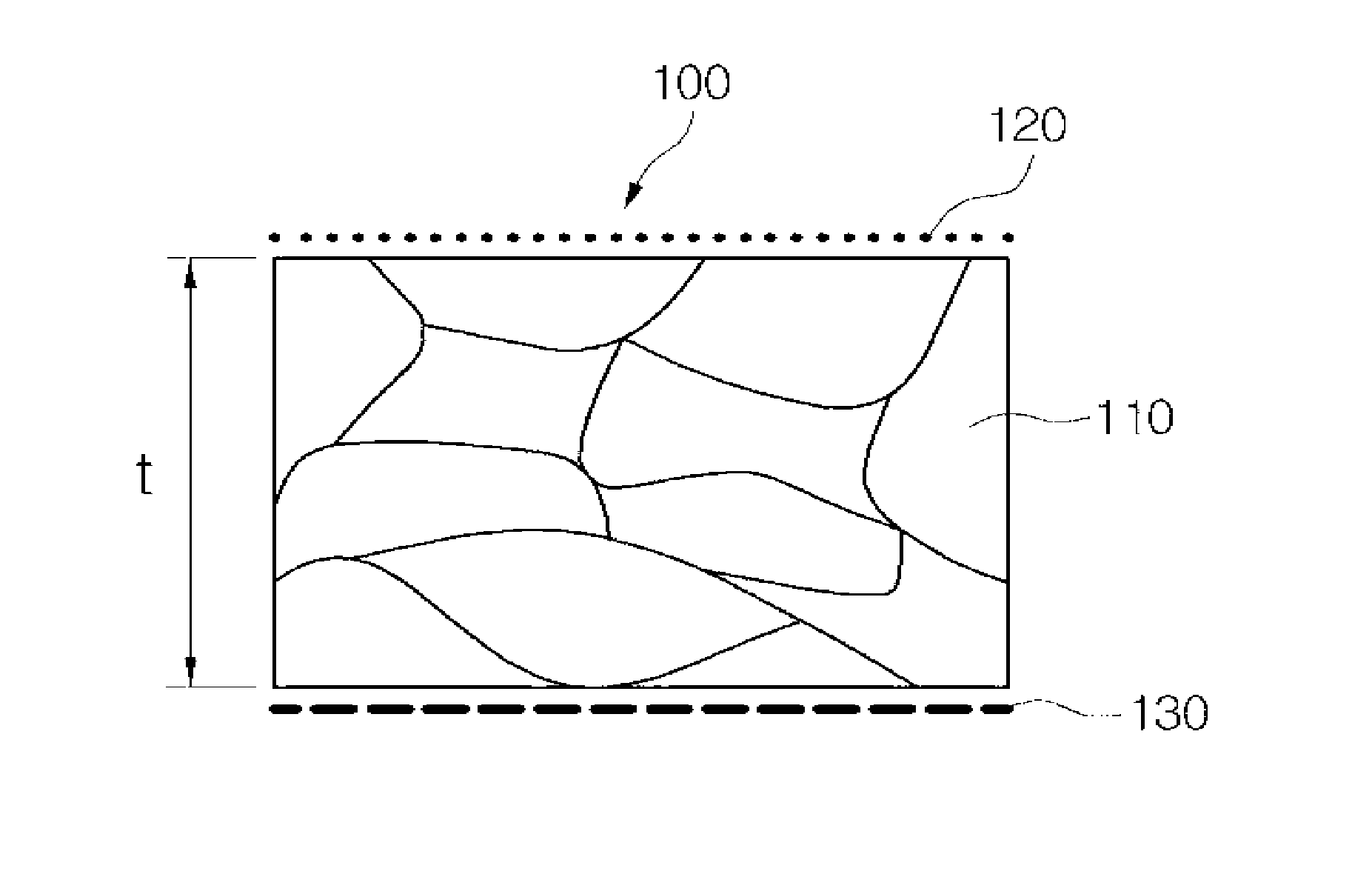

TECHNICAL FIELD[0001]The present invention relates to an inlaid type floor sheet having polyvinyl chloride chip and a method of manufacturing thereof, and more particularly to an inlaid type floor sheet having polyvinyl chloride chip and a method of manufacturing thereof, in which a plain-weave type dimensionally reinforcing layer is provided at a lower side of the inlaid type floor sheet having polyvinyl chloride chip, thereby improving durability, realizing dimensional stability and balance of a product and increasing adhesive force with a construction floor.BACKGROUND ART[0002]FIG. 1 is a cross-sectional view of a conventional inlaid type floor sheet having polyvinyl chloride chip (hereinafter, called ‘floor sheet’).[0003]As shown in FIG. 1, the conventional floor sheet 10 is a non-foaming type and includes an inside layer 11 which is adhered to a construction floor, a dimensionally reinforcing layer 12 which is disposed on the inside layer 11 and formed of glass fiber, a polyvin...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04F15/10

CPCE04F15/102E04F15/107B32B5/22B32B5/24B32B5/30B32B2255/04B32B2264/0242B32B2307/554B32B2307/732B32B2471/00Y10T428/26Y10T428/249921Y10T442/30B32B27/12B32B5/04E04F15/10

Inventor PARK, SUNG HASUNG, JAE WANKIM, DAE JINJANG, KI JAE

Owner LG HAUSYS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com