Process for obtaining magnetic cellulose paper and the respective product

a technology of magnetic cellulose and paper, which is applied in the field of process for the manufacture of paper with magnetic properties and the respective product, can solve the problems of high production cost, high operating cost machinery, and relatively high thickness, and achieve excellent practical and functional results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

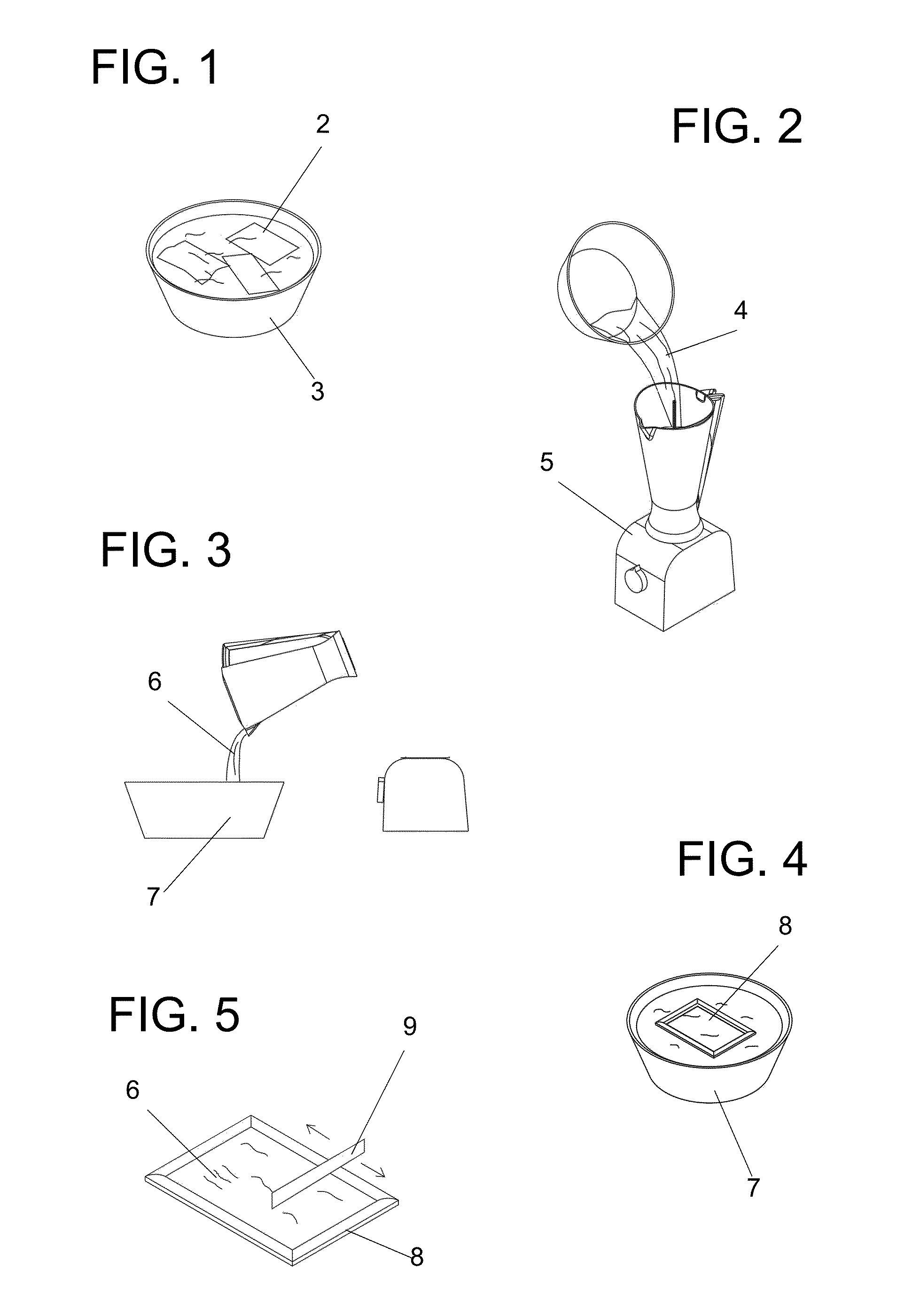

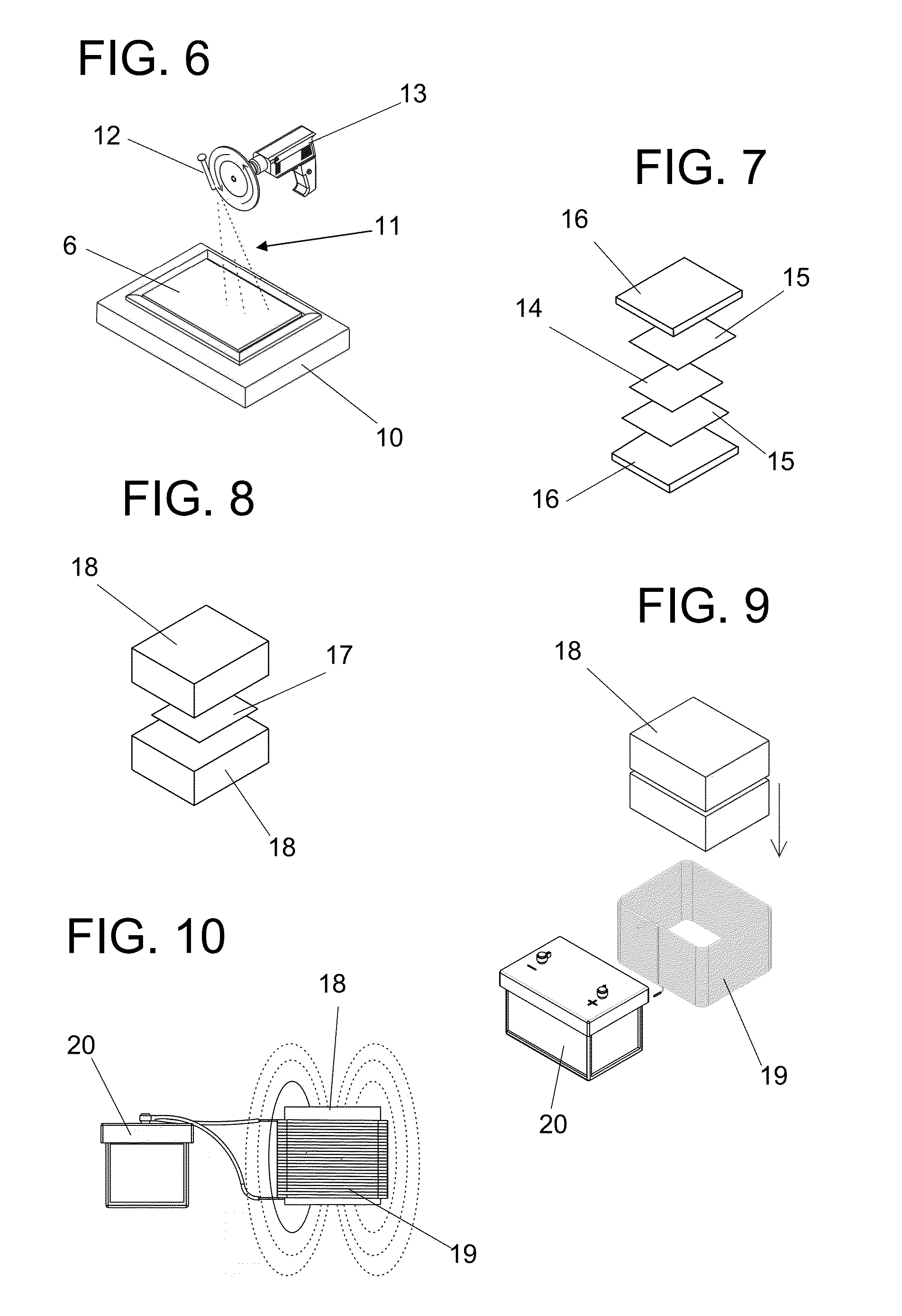

[0028]In compliance with the drawings above, the “PROCESS FOR OBTAINING MAGNETIC CELLULOSE PAPER AND THE RESPECTIVE PRODUCT” refers to a manufacturing method of a magnetic paper and the respective product.

[0029]The presented magnetic cellulose paper comprises a sheet of paper that can have different densities and have magnetized metallic particles or magnet particles embedded in its cellulose fibers.

[0030]Its manufacturing process involves the use of the following equipments and components:

[0031]Paper.

[0032]Water.

[0033]Mold with thin screen.

[0034]Cloth.

[0035]Spatula or spoon.

[0036]Containers.

[0037]Granules of ferromagnetic material.

[0038]Hard magnet.

[0040]Two wooden boards.

[0041]Newspaper.

[0042]The method for obtaining the magnetic cellulose paper (1) consists of the following stages:

[0043]1. Leave the post-use papers (2) to soak for 24 hours in a container (3), making sure all are covered with water.

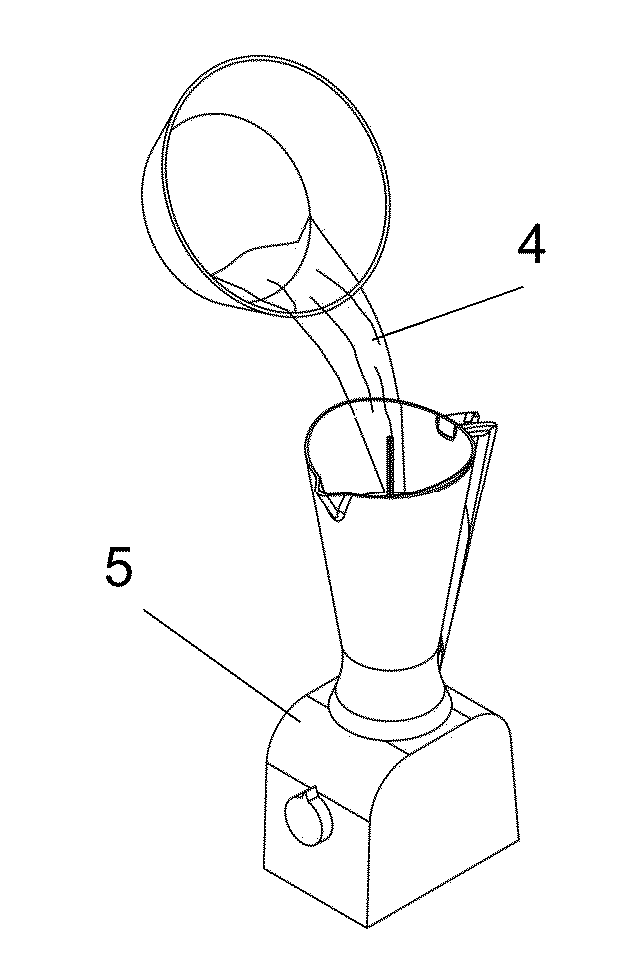

[0044]2. Then pour the obtained cellulose pulp (4) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetic | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com