Method and apparatus for achieving a high efficiency in an open gas-turbine (combi) process

a gas turbine and open gas technology, applied in the direction of combined combustion mitigation, turbine/propulsion fuel heating, steam engine plants, etc., can solve the problems of high energy loss of waste heat boilers, steam turbine processes, and inability to achieve high efficiency, so as to achieve a smaller energy loss and great efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

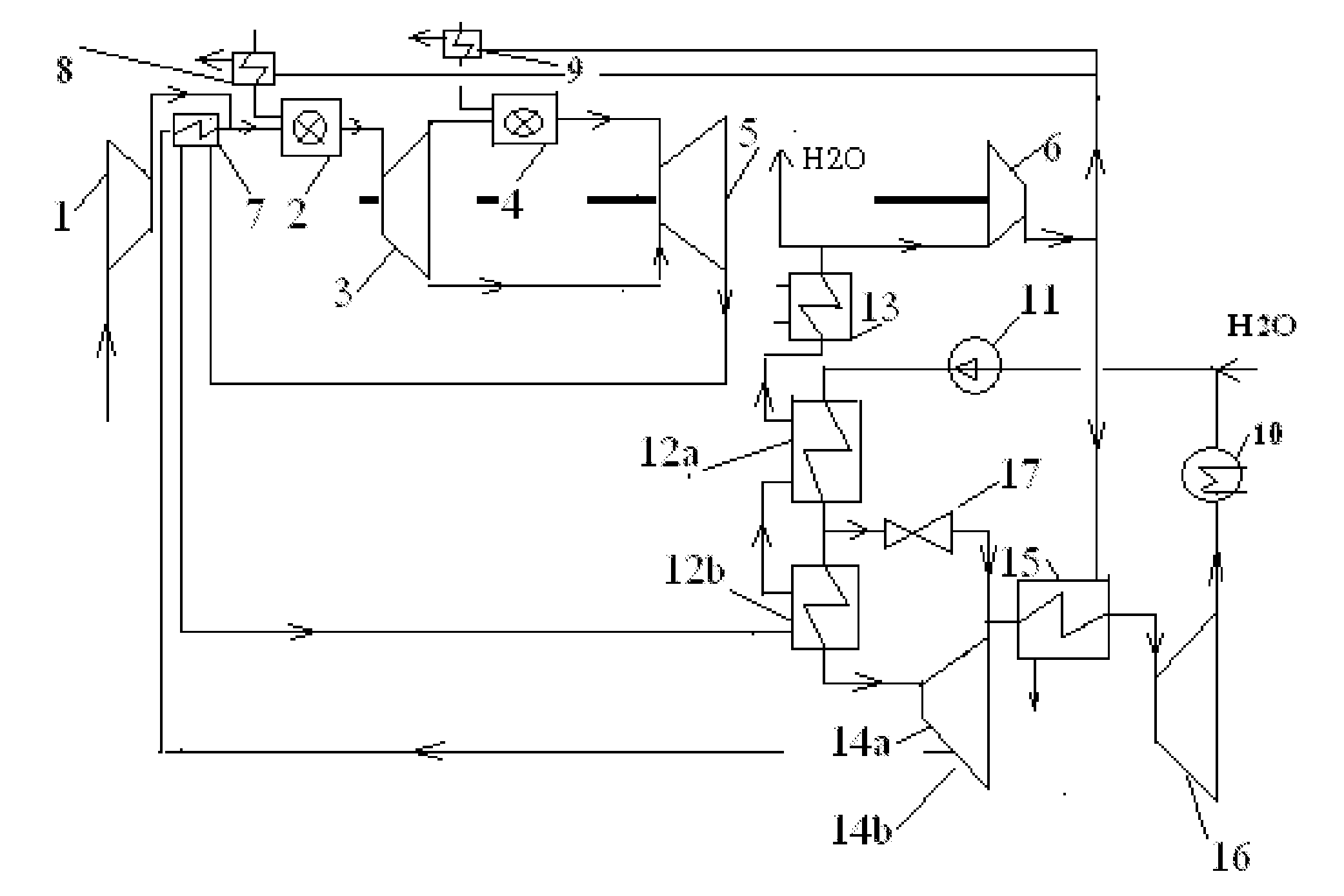

[0032]FIG. 1 shows an open gas-turbine (combi) process, in which a supercharger (1) compresses air, which is burned with fuel in a first combustion chamber (2), which is followed by a first turbine (3), a second combustion chamber (4), a second turbine (5), and a preheating heat exchanger (7), in which primary bleed steam coming from the secondary process is preheated.

[0033]The combustion gases go from the preheating heat exchanger (7) to a waste-heat boiler (12a, b), in which the feed water of the secondary process is vaporized. For reasons of clarity, the water-heat boiler is shown in two parts (12a, b), though in reality it consists of a single heat exchanger. Preheating of the maximum-pressure water takes place mainly in waste-heat boiler (12a) and vaporization and superheating mainly in waste-heat boiler (12b). The combustion gases expand in the second turbine (5) to a pressure lower than that of the surrounding atmospheric pressure, when the combustion gases remaining after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com