Two-phase projectile with a proximal compression chamber

a compression chamber and projectile technology, applied in the field of man-powered devices, can solve the problems of increasing the velocity of one component and discharging the velocity of the other component, and achieve the effect of easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

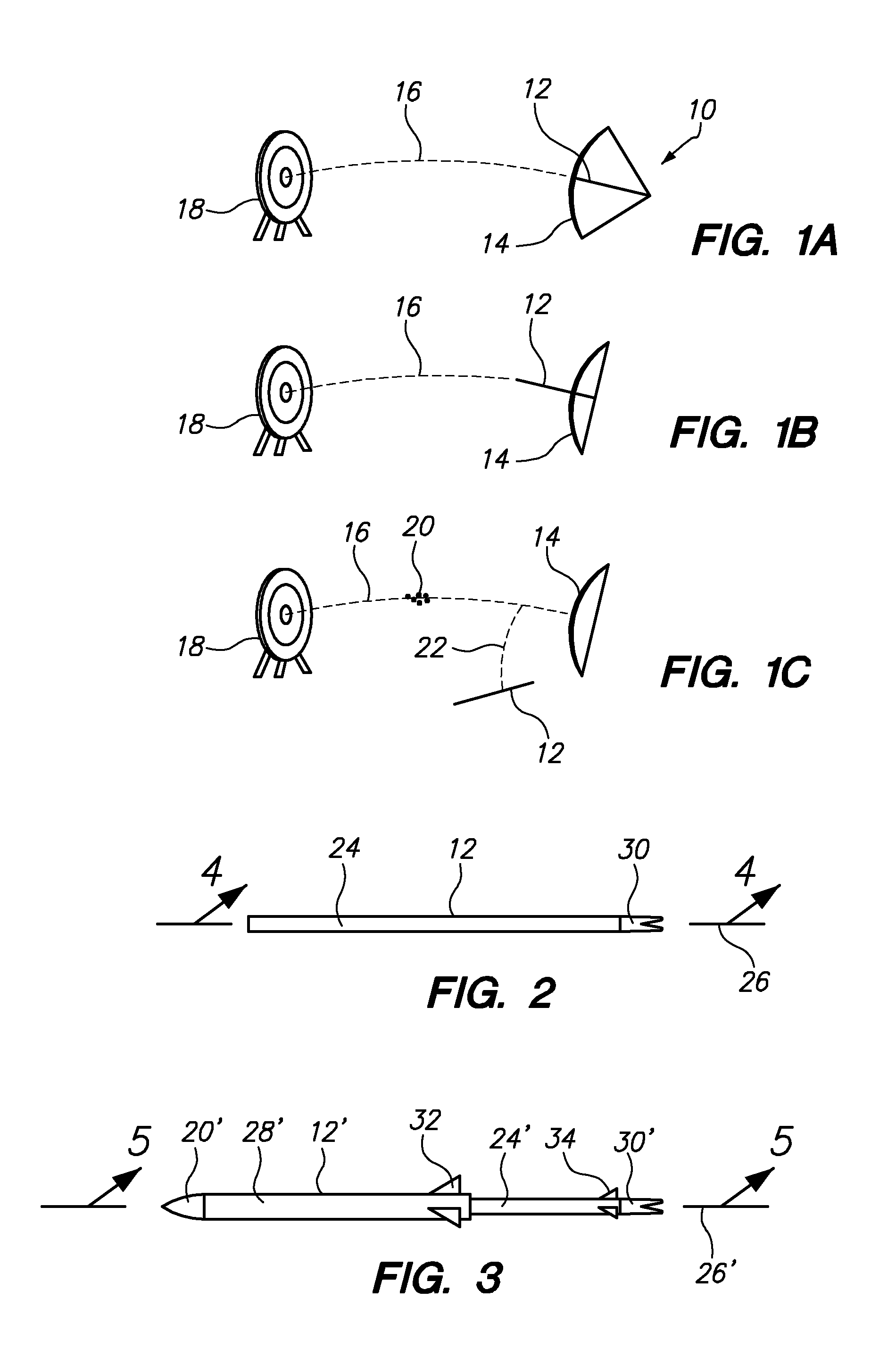

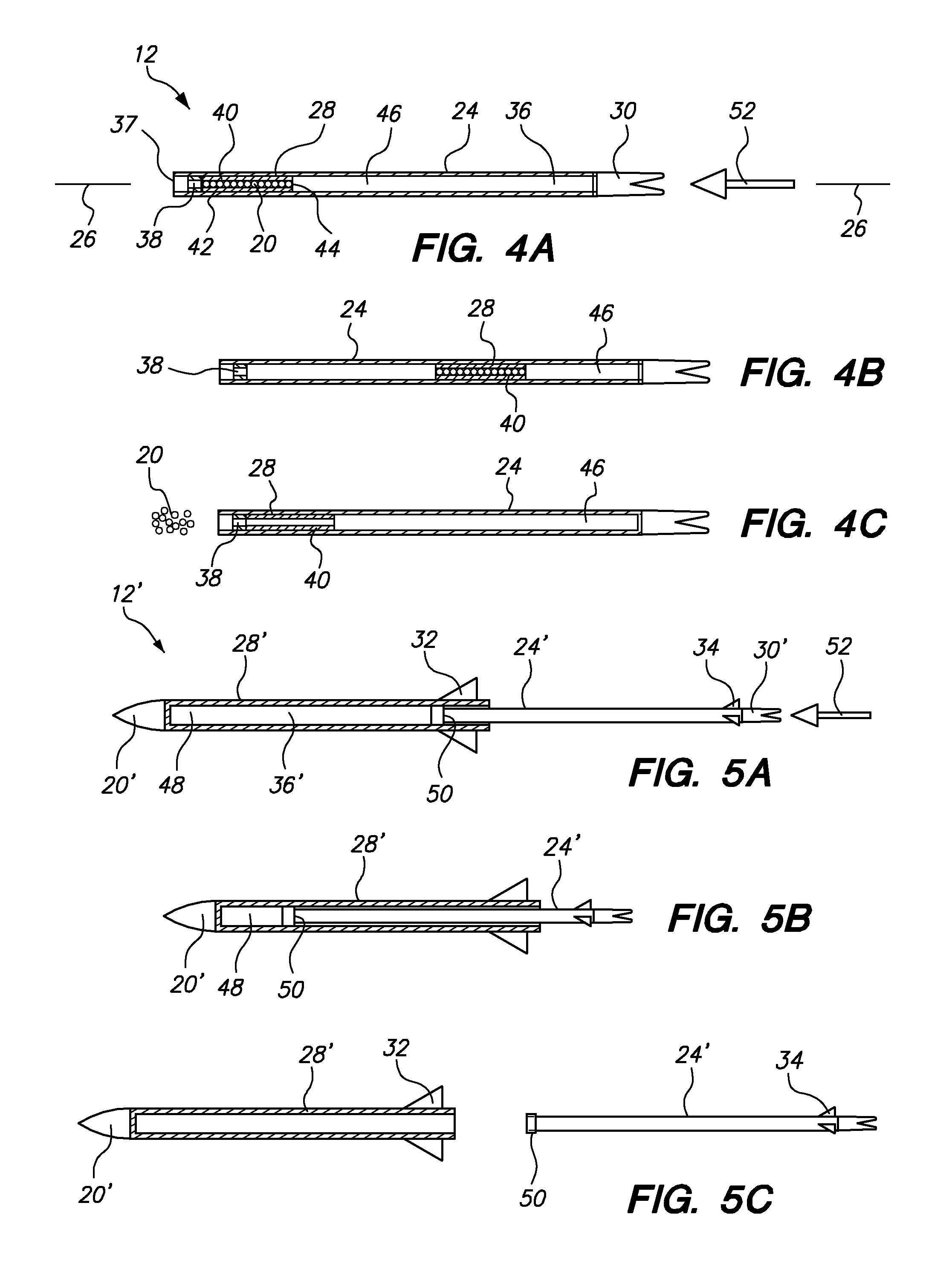

[0039]Referring initially to FIG. 1A, a device in accordance with the present invention is shown and is generally designated 10. As shown, the device 10 includes a projectile 12 and a man-powered launcher 14. In the particular case of the device 10 that is shown in FIG. 1A, the launcher 14 is a vertical bow of a type well known in the art. The launcher 14, however, could as well be a crossbow (not shown) or an air gun (not shown), both of which are of types well known in the pertinent art.

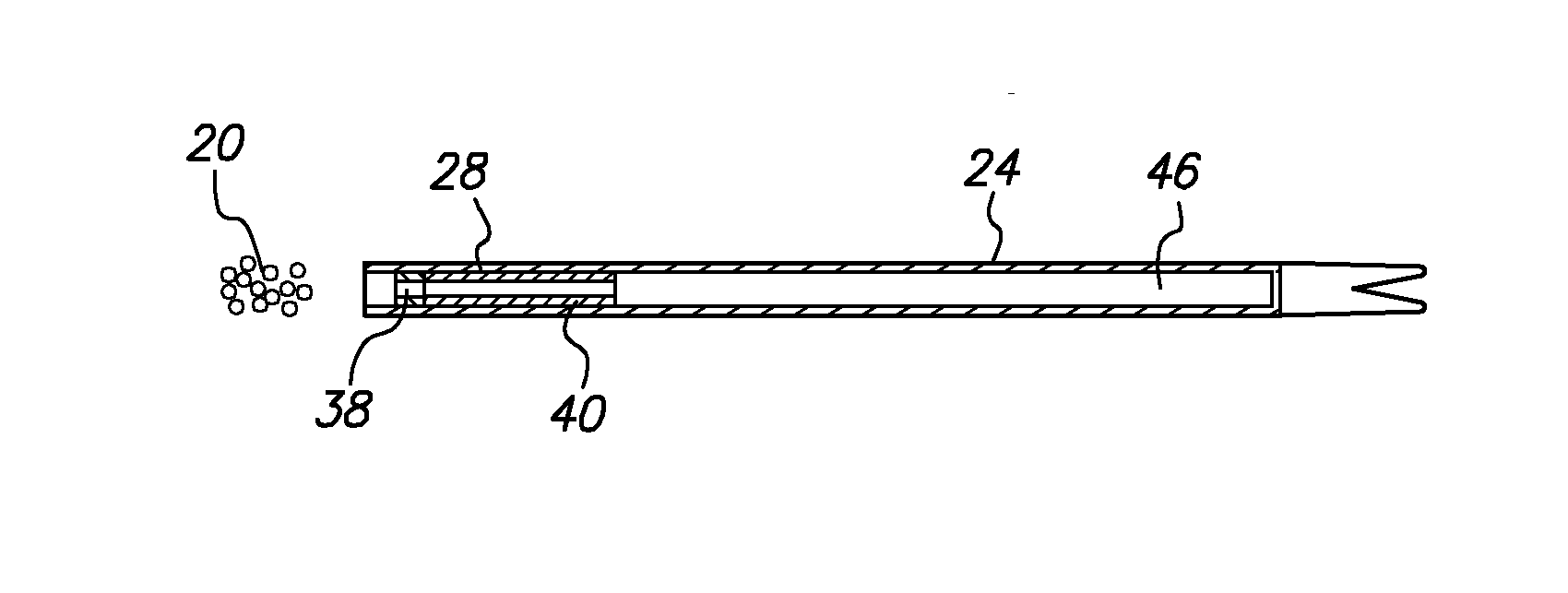

[0040]As illustrated sequentially in FIGS. 1A, 1B and 1C, a purpose of the present invention is to use the launcher 14 to propel the projectile 12 along a flight path (dashed line) 16 toward a target 18. In sequence, FIG. 1A shows the launcher 14 in a configuration for firing the projectile 12. FIG. 1B then shows the projectile 12 as it is being released from the launcher 14. And, FIG. 1C shows the projectile 12, and its payload 20 after it has been separated from the projectile 12 in flight, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com