Toothed-Lobed Gear Pump

a gear pump and toothed-lobe technology, applied in the field of gear pumps, can solve the problems of high shearing stress and high pressure, and the milling action is detrimental to shear sensitive liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

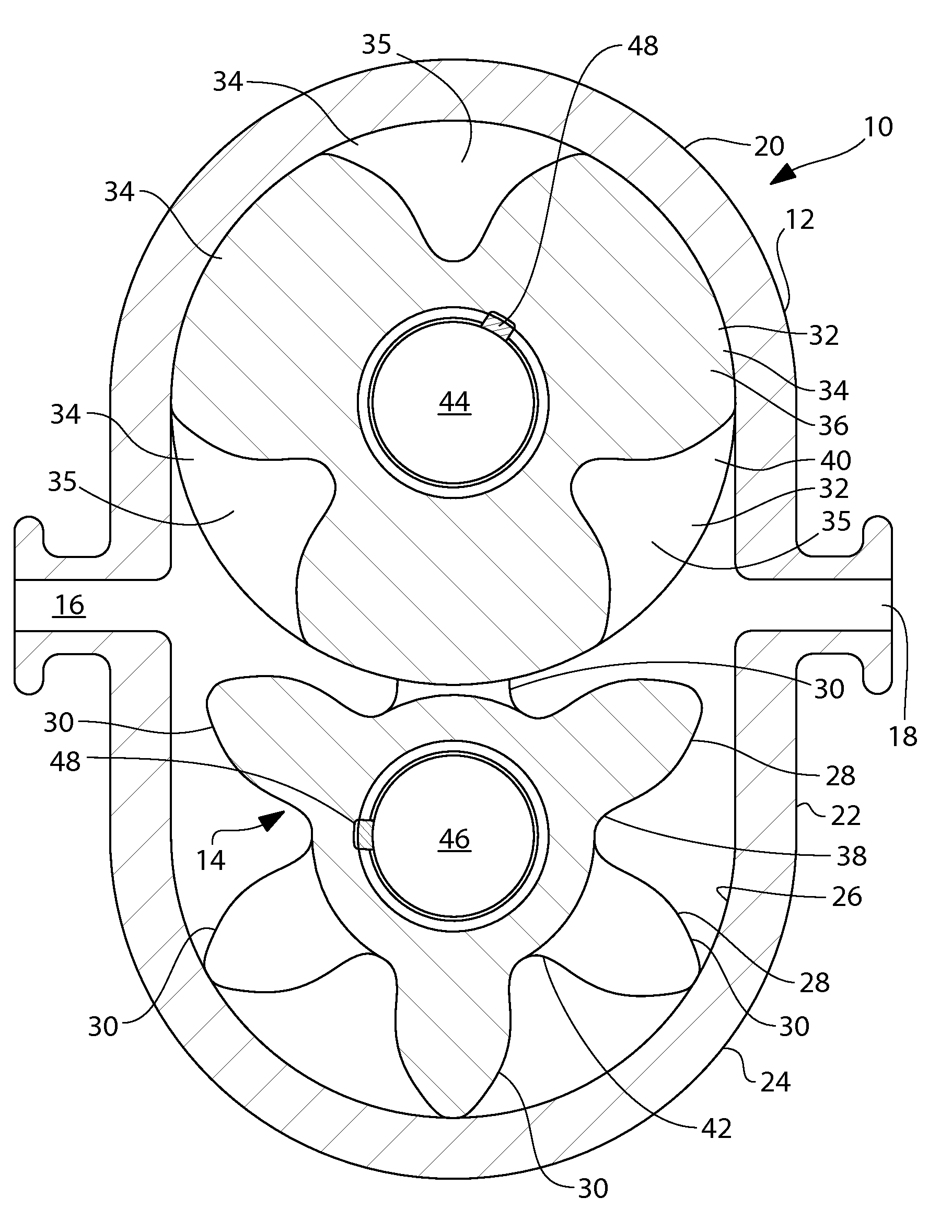

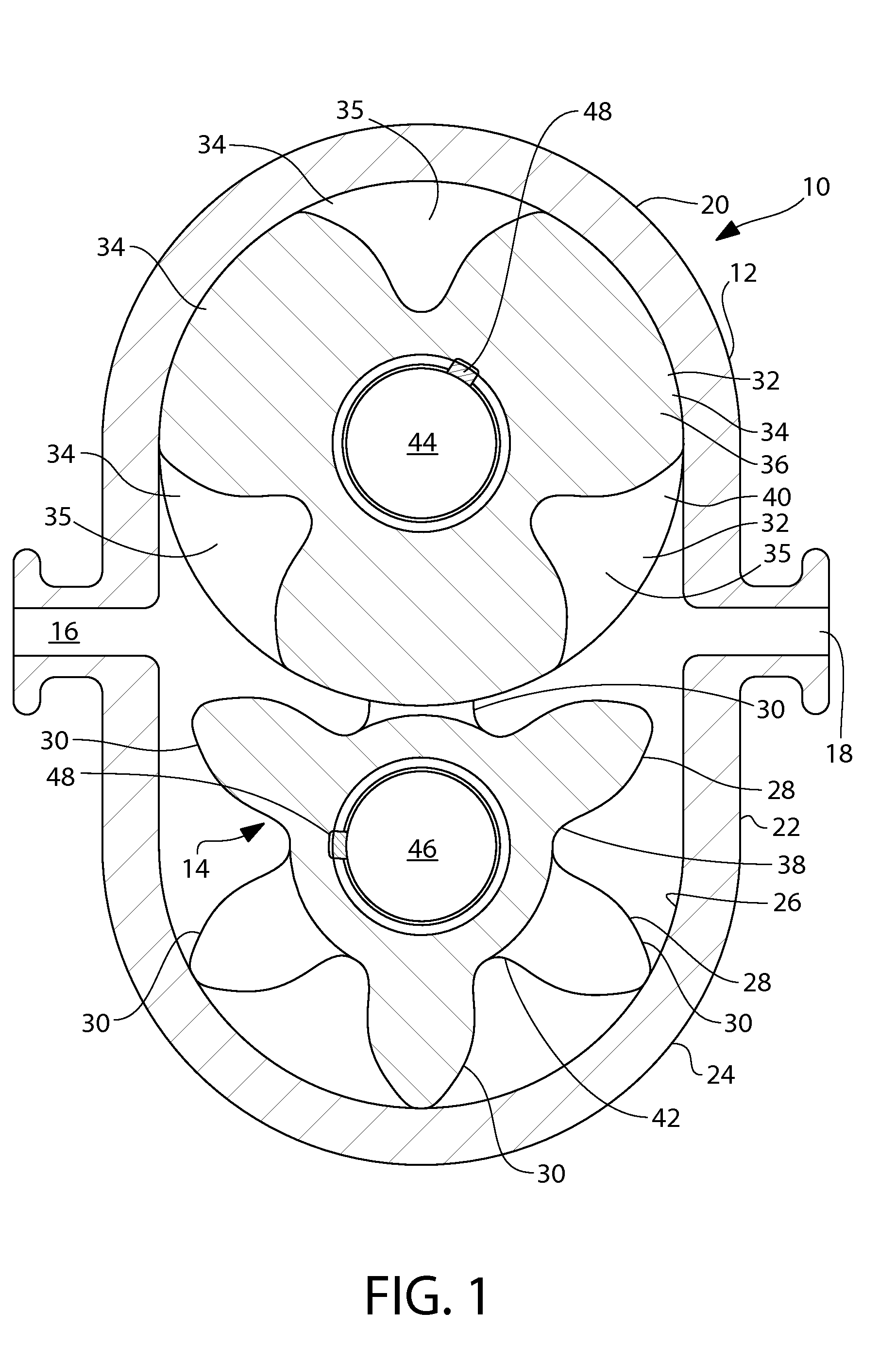

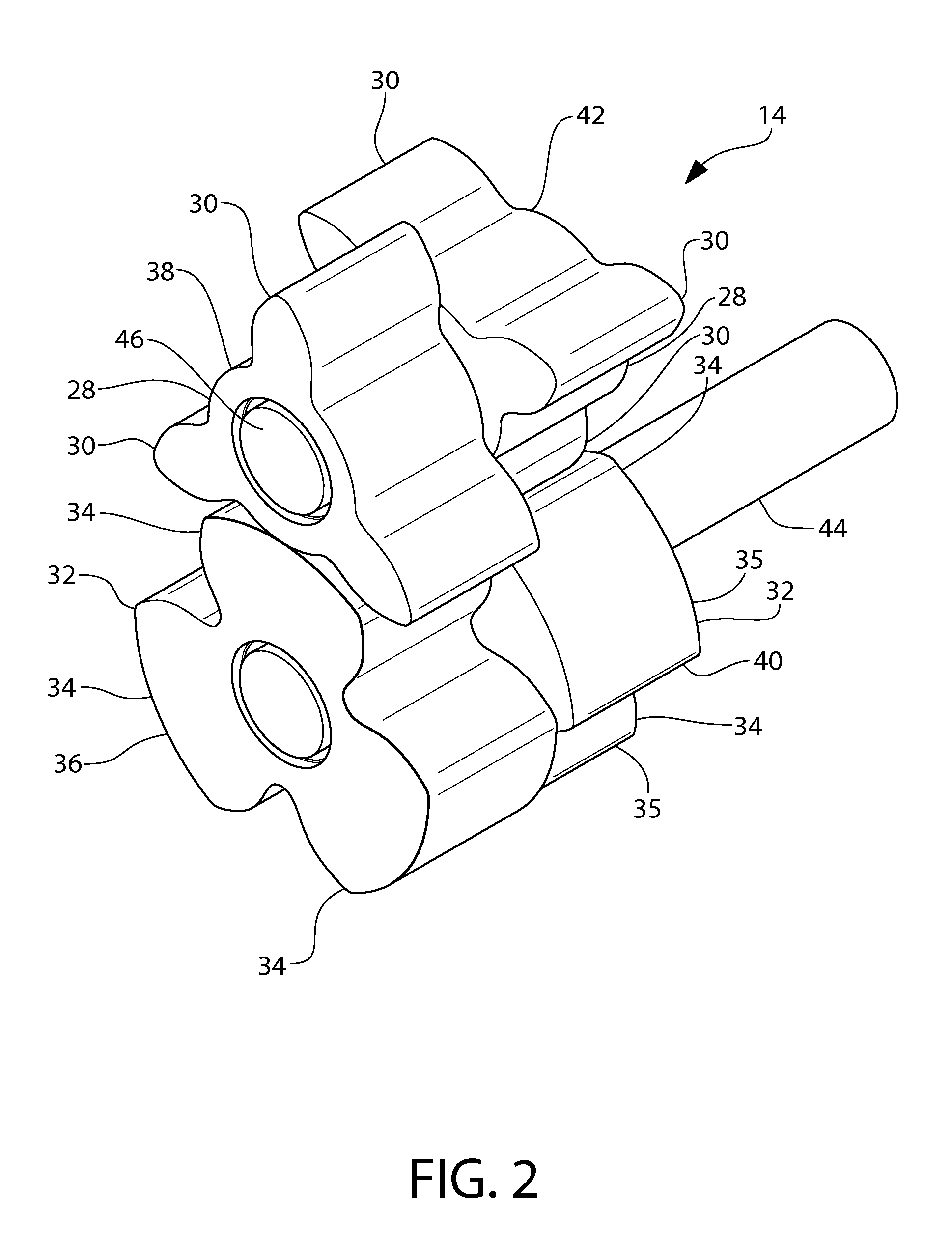

[0021]The exemplary embodiments of the pump are described with reference to FIGS. 1-4. While not being limited to a particular theory, the exemplary embodiments include both spur gears and lobed gears intermeshed to create larger volume pockets in gear sets of a given size. The pockets are larger than the pockets that exist in current lobe pumps and provide the benefit of a pump that better handles shear sensitive liquids. Preferably, the profiles of the spur teeth and of the lobes are involute-shaped to provide rolling contact and a fixed pressure angle between the spur teeth and lobes during engagement. The involute-shaped profiles prevent the teeth and lobes from rubbing and sliding against one another during engagement. Rubbing and sliding increases friction, power consumption, wear and galling to the meshing spur teeth and lobes. While traditional lobe pumps require an external gearbox to synchronize its pump rotors to one another and to keep the rotors from rubbing during oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com