Flow manipulating arrangement for a turbine exhaust diffuser

a technology of turbine exhaust and flow control, which is applied in the direction of machines/engines, stators, liquid fuel engines, etc., can solve problems such as inefficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

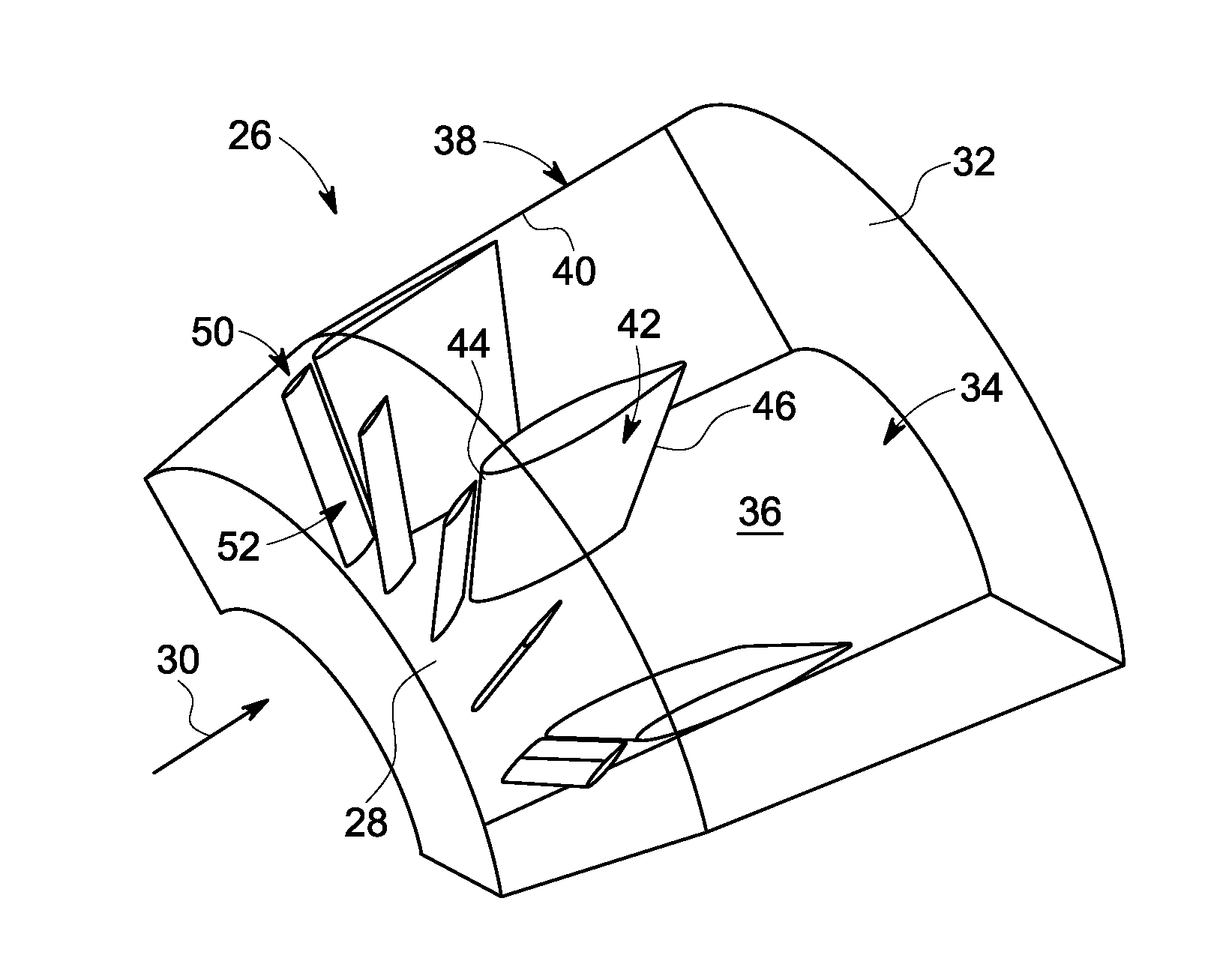

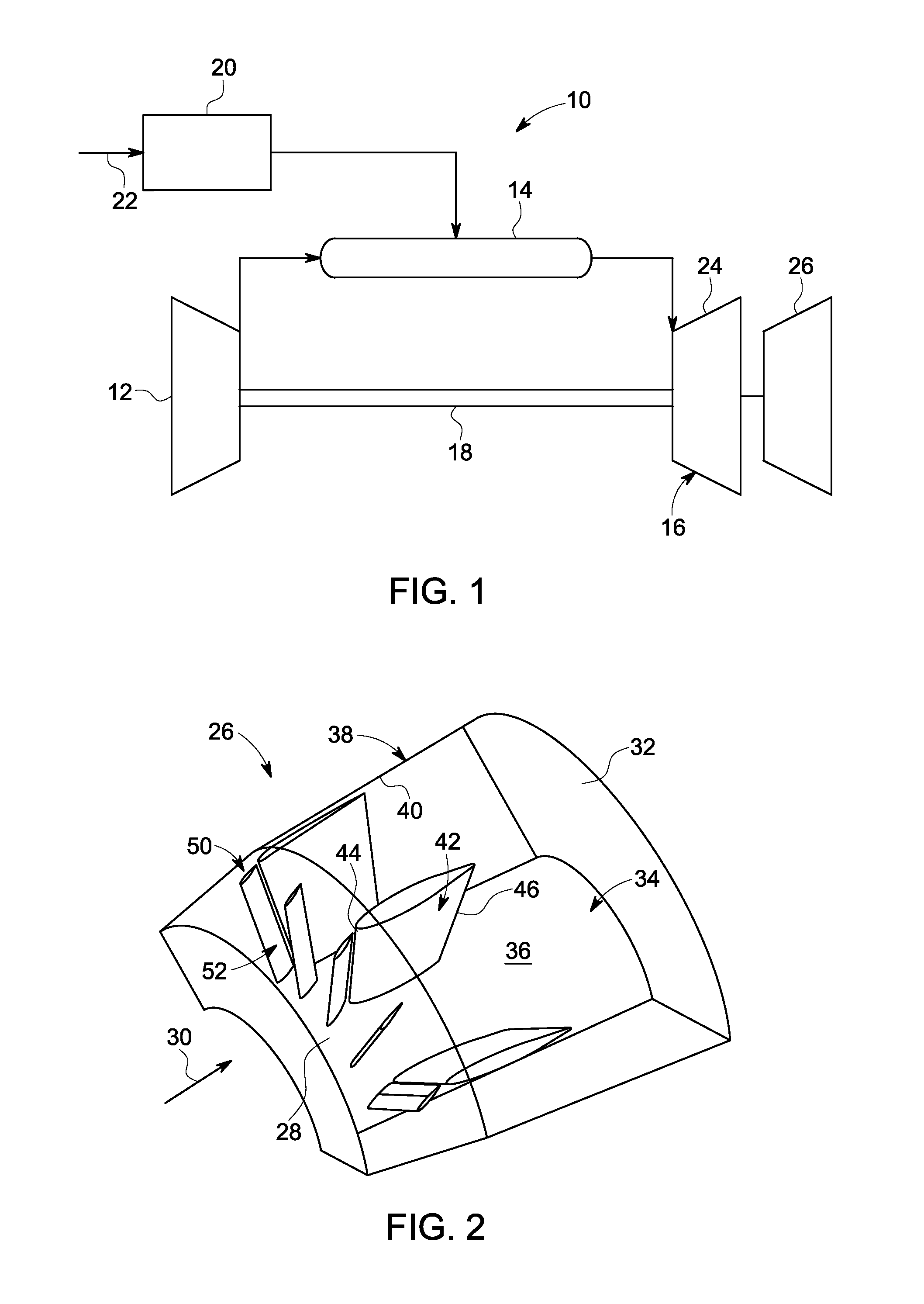

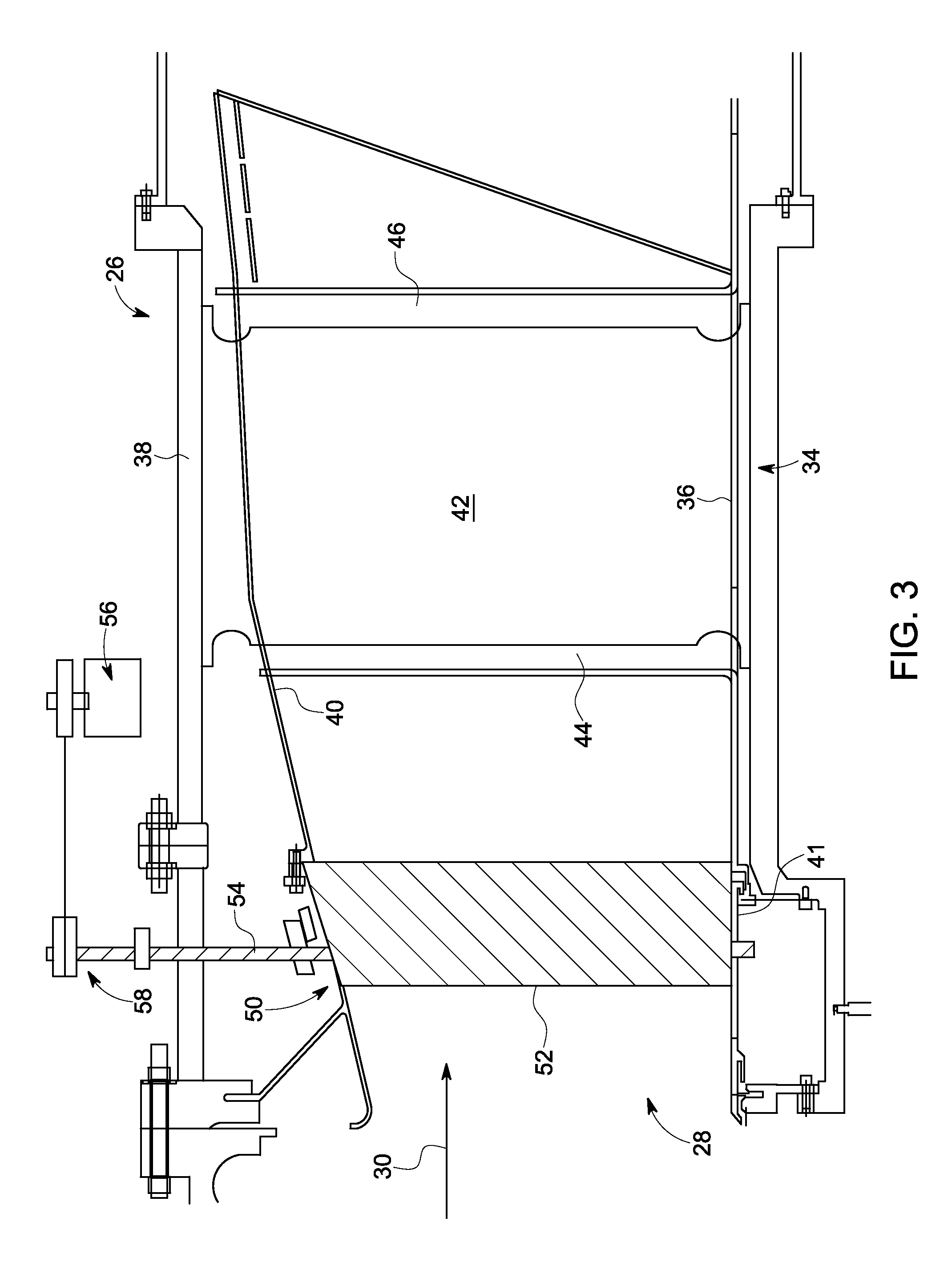

[0023]Referring to FIG. 1, a turbine system, such as a gas turbine system, for example, is schematically illustrated with reference numeral 10. The turbine system 10 includes a compressor section 12, a combustor section 14, a turbine section 16, a shaft 18 and a fuel nozzle 20. It is to be appreciated that one embodiment of the turbine system 10 may include a plurality of compressors 12, combustors 14, turbines 16, shafts 18 and fuel nozzles 20. The compressor section 12 and the turbine section 16 are coupled by the shaft 18. The shaft 18 may be a single shaft or a plurality of shaft segments coupled together to form the shaft 18.

[0024]The combustor section 14 uses a combustible liquid and / or gas fuel, such as natural gas or a hydrogen rich synthetic gas, to run the turbine system 10. For example, fuel nozzles 20 are in fluid communication with an air supply and a fuel supply 22. The fuel nozzles 20 create an air-fuel mixture, and discharge the air-fuel mixture into the combustor se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com