Adhesive and bolt-on type gun grip, gun equipment and accessory systems

a gun grip and bolt-on technology, applied in the field of firearm accessories, can solve the problems of not providing any improved or enhanced functionality, brittleness, and brittleness of hard plastic covers, and achieve the effects of reducing noise, reducing friction, and improving gripping performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

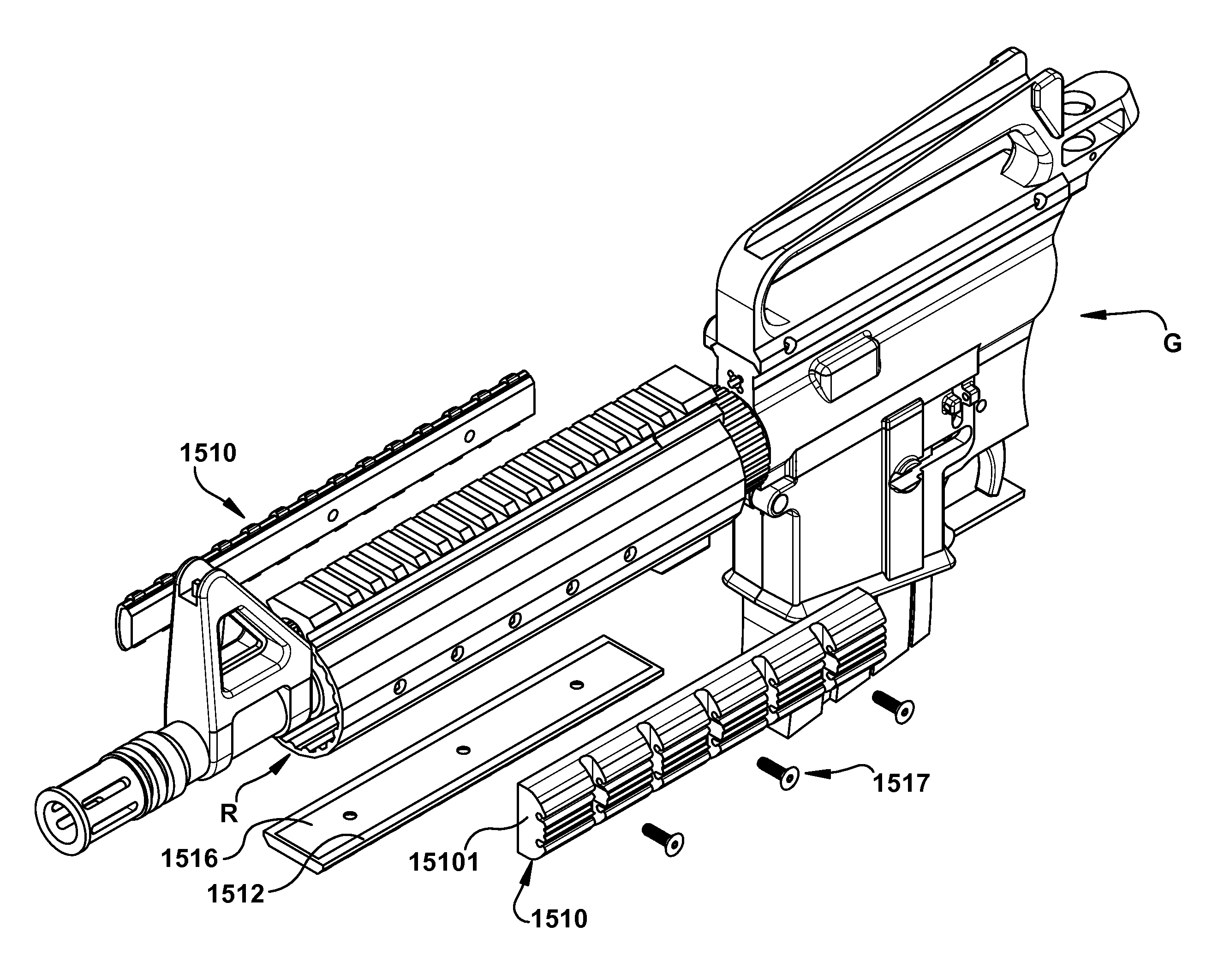

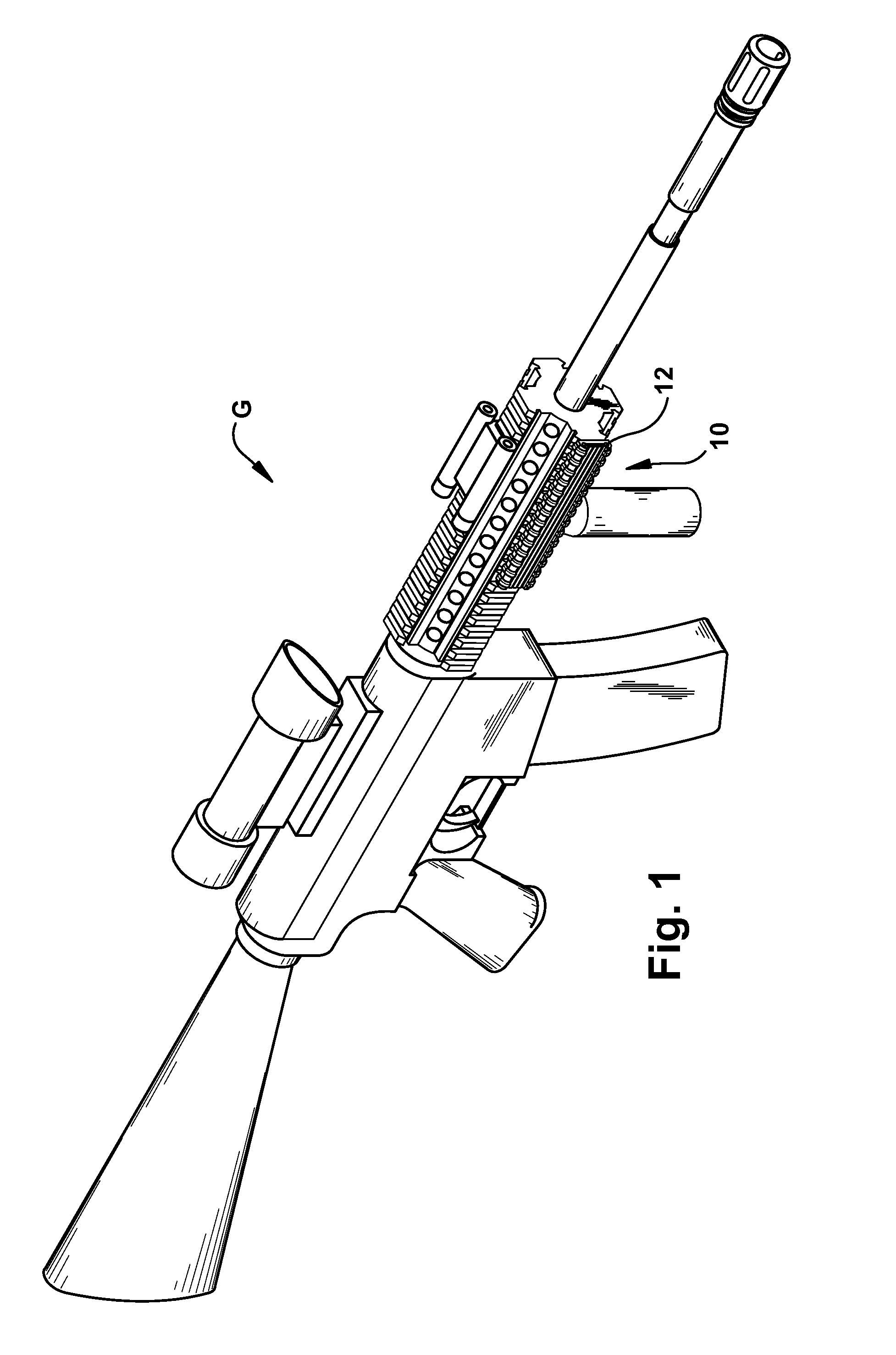

[0030]FIG. 1 illustrates a gun G, such as a rifle or carbine, with a typical installation of multiple rails such as MIL-STD-1913 or NAR rails arranged about the barrel, for example in a four-sided arrangement as shown. As noted, any of the attachments, components, accessories and systems can be used on any MIL-STD-1913 rail or similar rails (referred to herein generally and collectively as “rails”) in any arrangement or length or location. A representative embodiment of a gun accessory is indicated generally at 10, for example in the form of a grip or cover and particularly suited and configured for attachment to a gun rail, and includes a body 12 which is molded of a polymeric material and preferably an elastic polymer or “elastomer” and thermoplastic elastomers which exhibit viscoelasticity in durometers in the approximate hardness ranges of, for example, 5 Shore A to 90 Shore A, 40 Shore A or lower end up to 80 Shore A, and a more preferred range of 40 Shore A to 70 Shore A, 40 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com