Secure Mounting of Excavation Equipment Teeth

a technology for mounting equipment and excavation equipment, which is applied in the field of secure mounting of excavation equipment teeth, can solve the problems of affecting the service life of the tooth, the gap between the tooth and the nose piece in the tooth pocket, and the tooth is always slightly loose on the nose piece, so as to prevent the penetration of grit and water, prevent the tooth from wiggling or loosening, and prevent the effect of wiggling looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

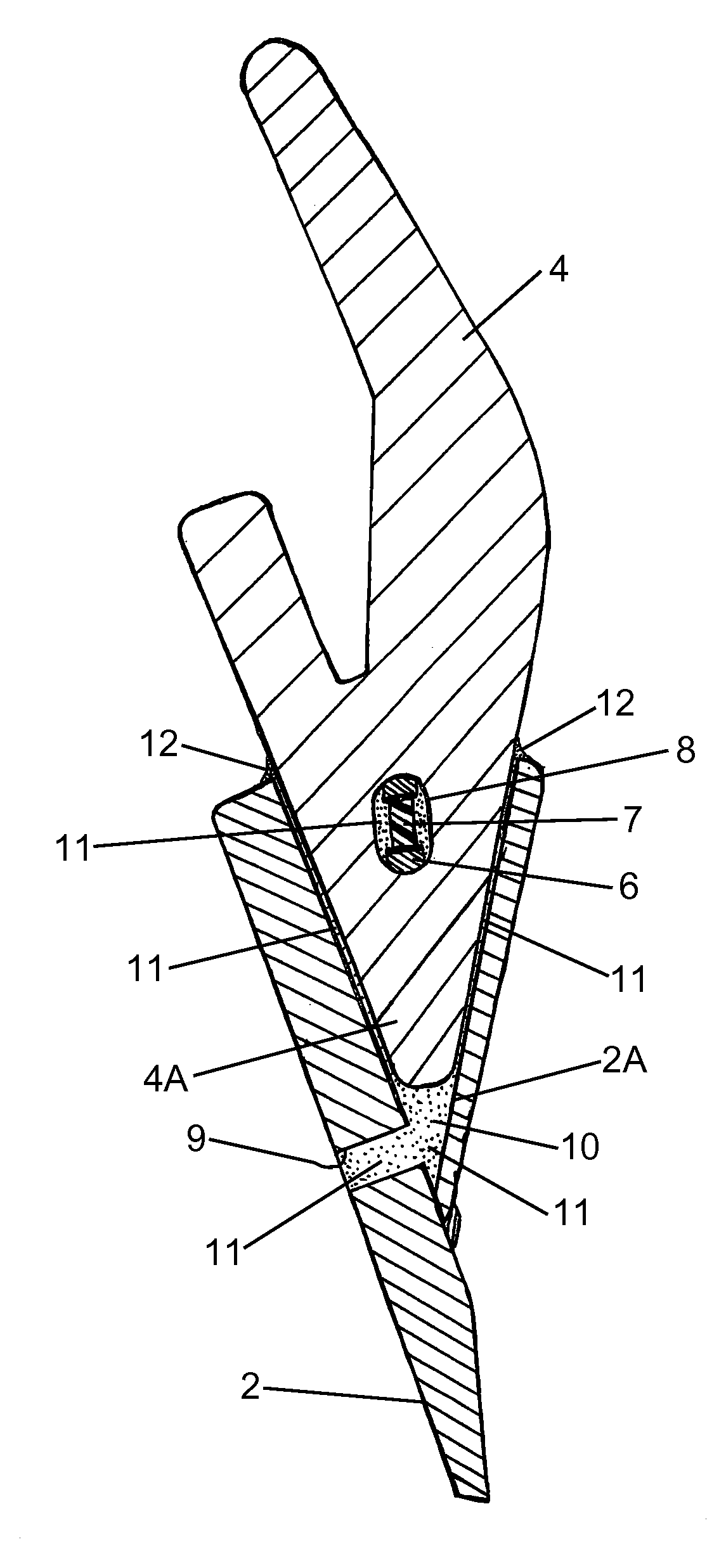

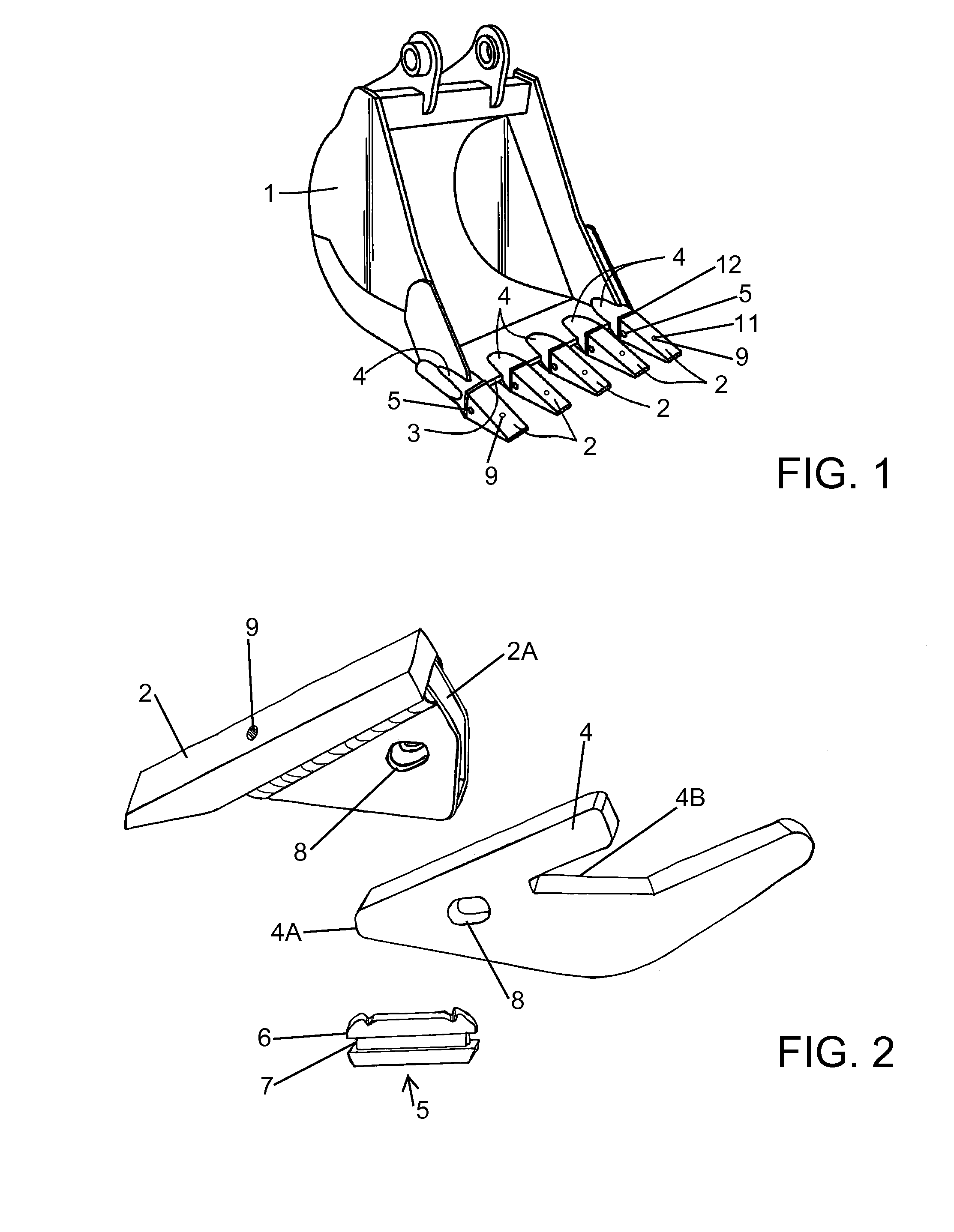

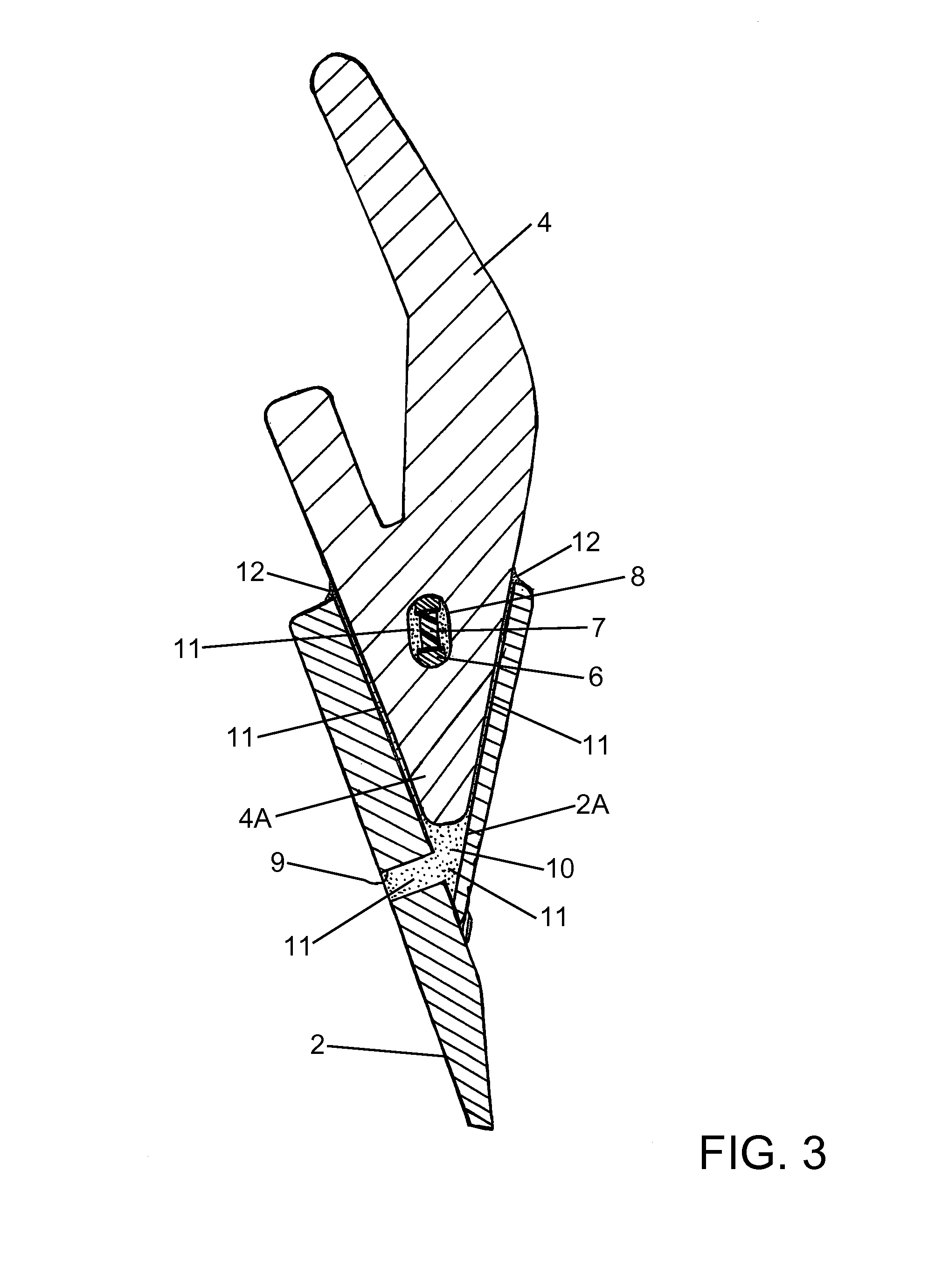

[0021]FIG. 1 schematically illustrates a typical small excavator bucket 1, as a representative example of a powered ground-engaging tool of excavating equipment. The present invention is not limited to excavator buckets, but rather applies to all powered ground-engaging tools of all excavating equipment, having replaceable ground-engaging wear points, such as the representative teeth 2 mounted on the bucket 1. Particularly, the teeth 2 are mounted on nose pieces 4, which are connected to the front digging edge 3 of the bucket 1. The nose pieces 4 may be bolted or welded onto the separate digging edge 3, or may be formed as an integral part of the digging edge 3. The nose pieces 4 generally represent any conventionally available nose pieces, shanks or adapters onto which replaceable teeth 2 or ground-engaging wear points are to be mounted. Sometimes the nose piece includes a first base piece that is connected to the digging edge 3 of the bucket 1, and a second adapter piece that is m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com