Method for operating a gas and steam turbine installation for frequency support

a technology of gas and steam turbines, applied in steam engine plants, machines/engines, mechanical equipment, etc., can solve problems such as power loss and efficiency during standby operation of installations, and achieve the effect of improving the power reserve availabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

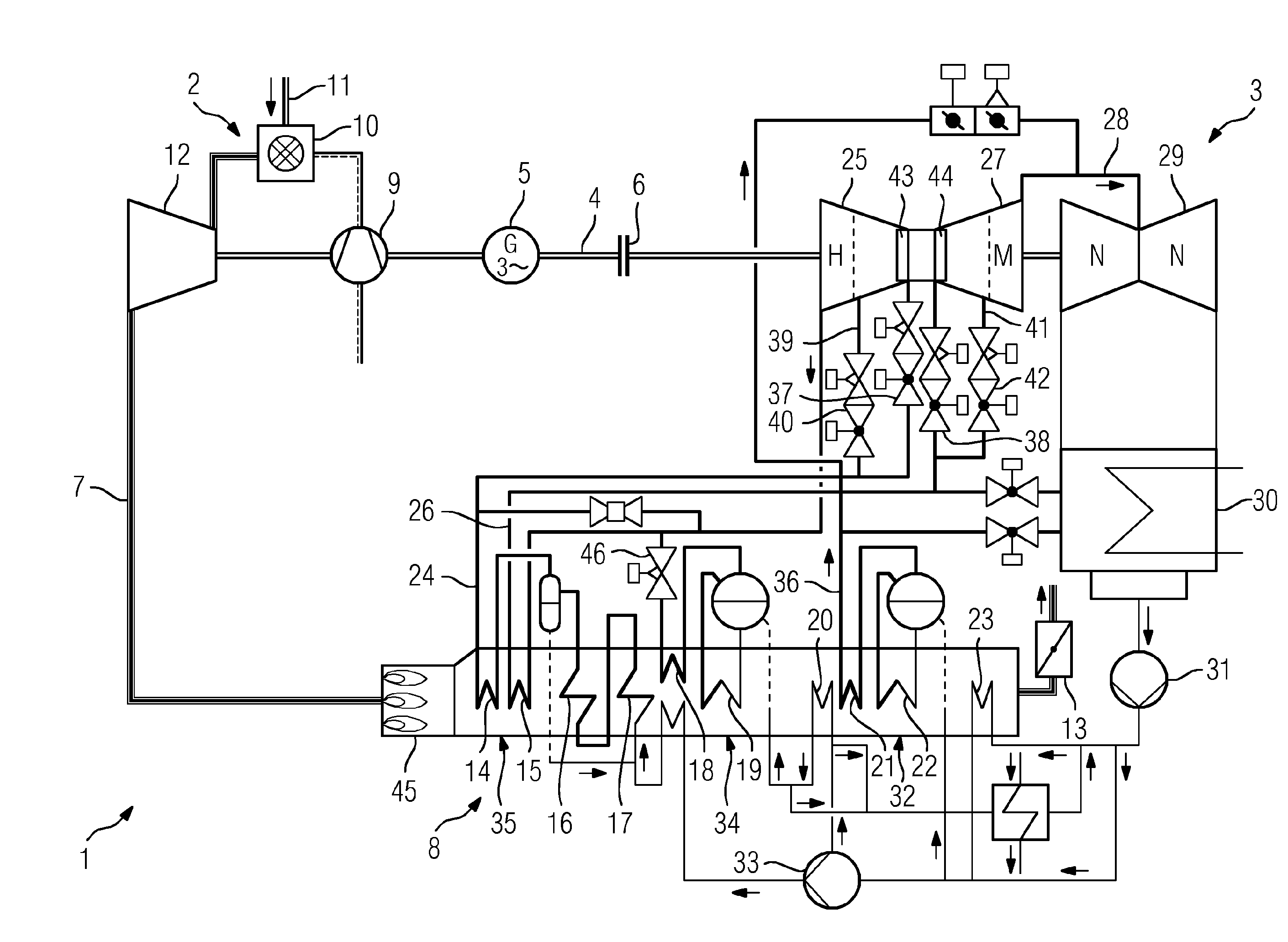

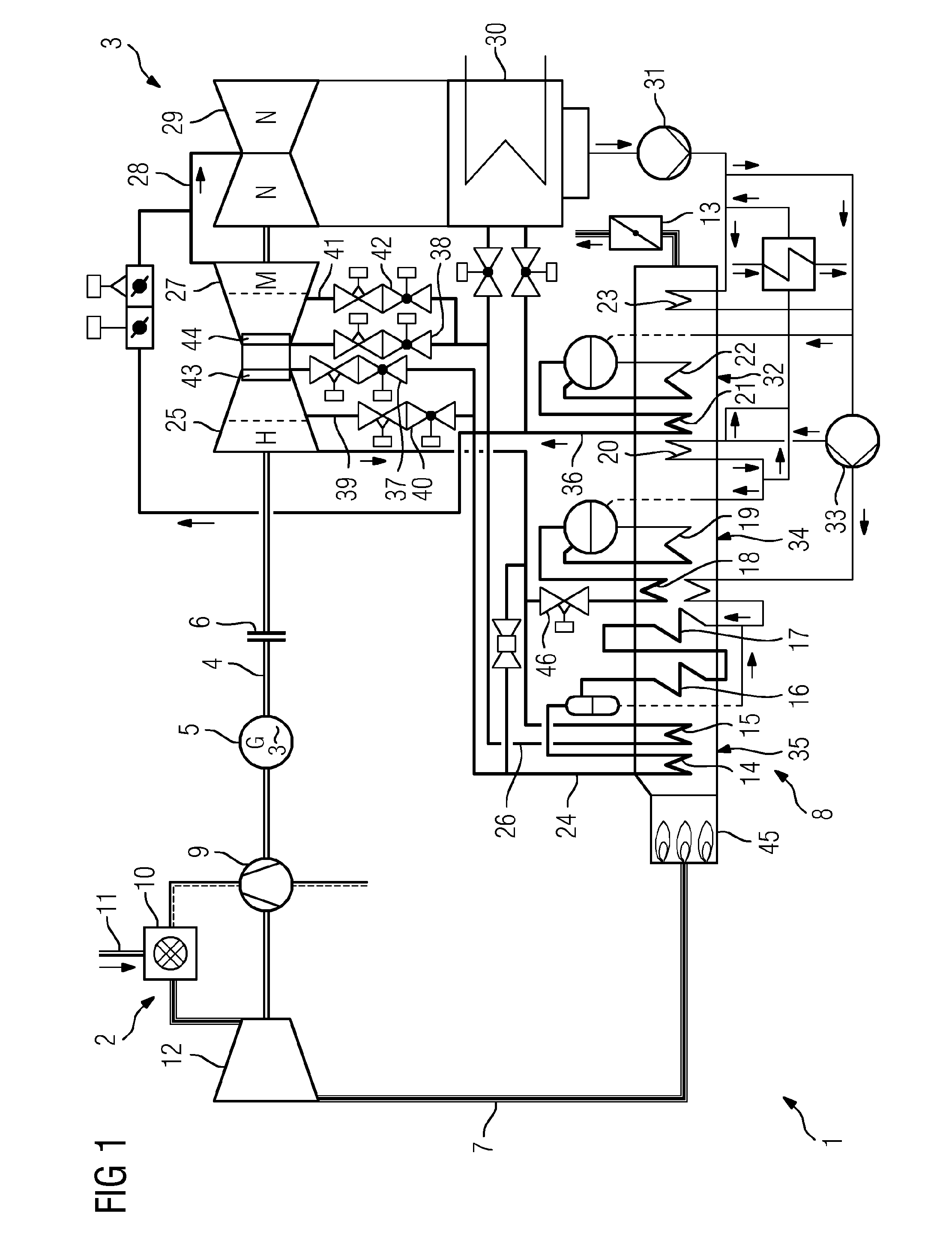

[0021]FIG. 1 shows a gas and steam turbine installation 1 which comprises a gas turbine 2 and a steam turbine 3. A rotor of the gas turbine, a rotor of a generator 5 and a rotor of the steam turbine 3 are coupled to one another by means of a shaft 4, wherein the rotor of the steam turbine 3 and the rotor of the generator 5 can be rotationally separated from one another and coupled to one another by means of a coupling 6. The rotors of the generator 5 and of the gas turbine 2 are fixedly interconnected. A flue gas outlet from the gas turbine 2 is connected, by means of an exhaust gas line 7, to a waste heat steam generator 8 which is provided for generating the working steam of the steam turbine 3 using waste heat from the gas turbine.

[0022]When the gas and steam turbine installation 1 is in operation, the rotating rotor of the gas turbine 2 drives, via the shaft 4, a compressor 9 by means of which combustion air is drawn in from the surroundings and fed to a combustor 10. There, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com