Electronic control unit having integrated circuit element and standalone test unit for integrated circuit element

a technology of integrated circuit elements and test units, which is applied in the direction of electronic circuit testing, measurement devices, instruments, etc., can solve the problems of difficulty in quick detail checks, affecting the reliability of electronic control units, and unable to individually check the various combination circuits, etc., to achieve high reliability, improve reliability, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

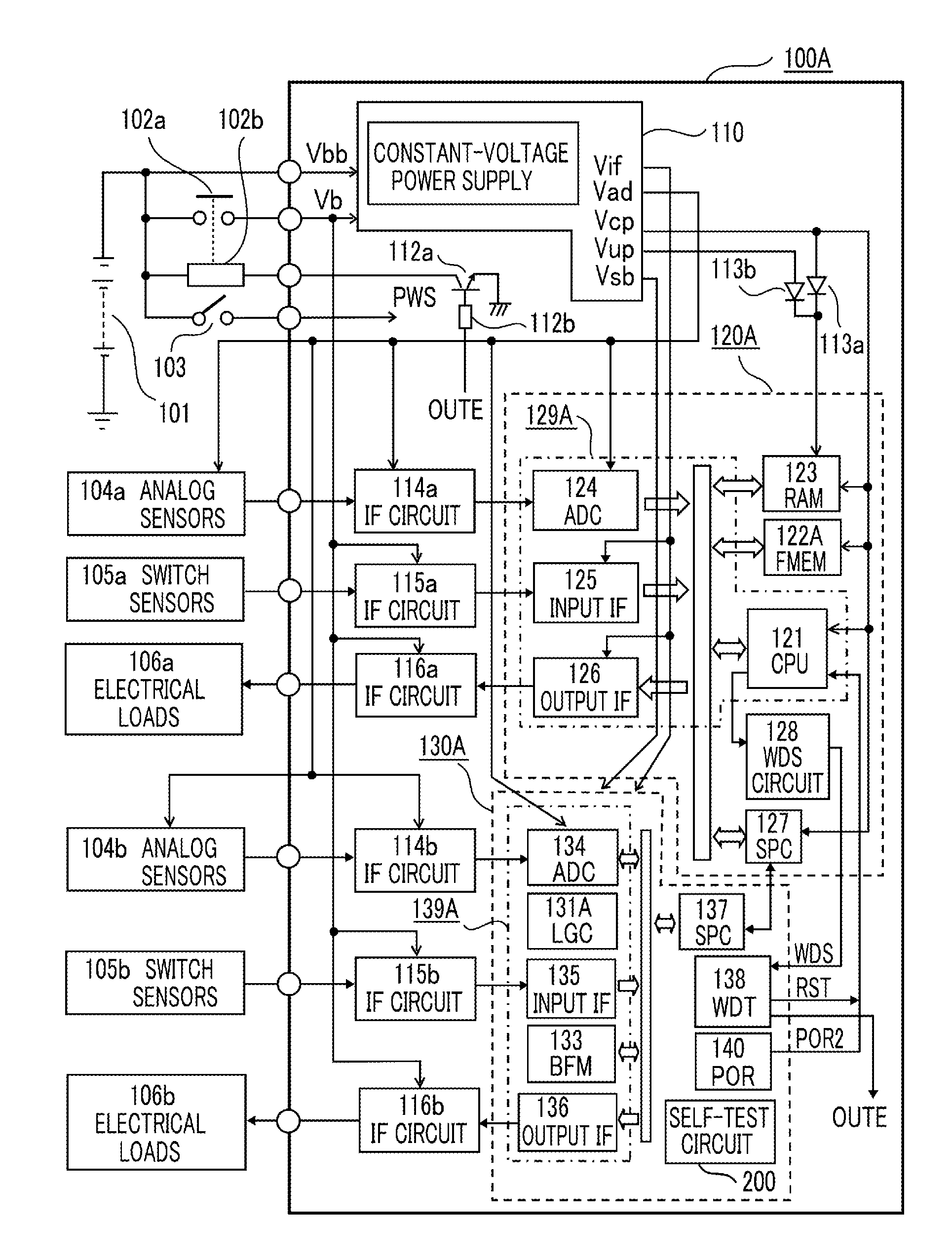

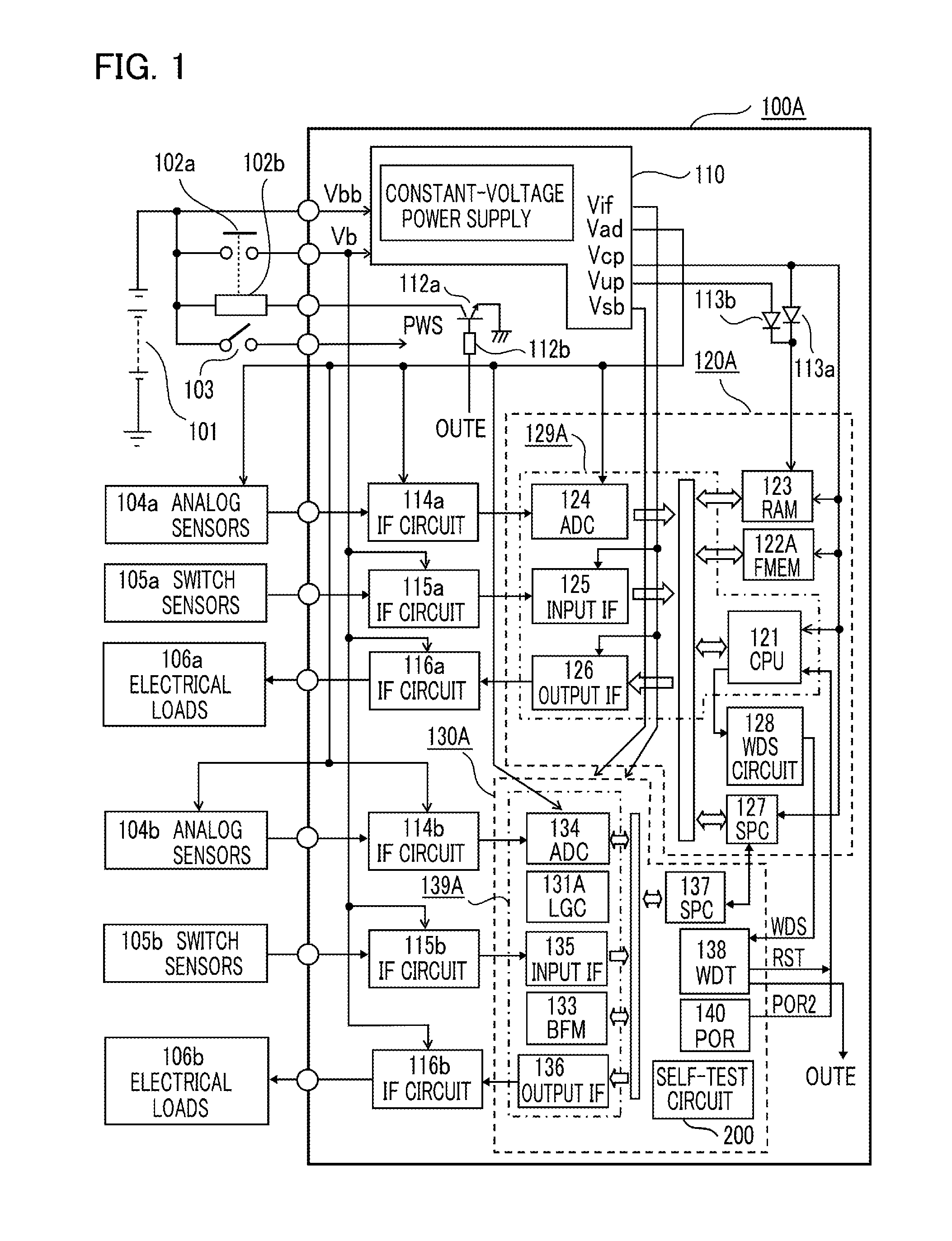

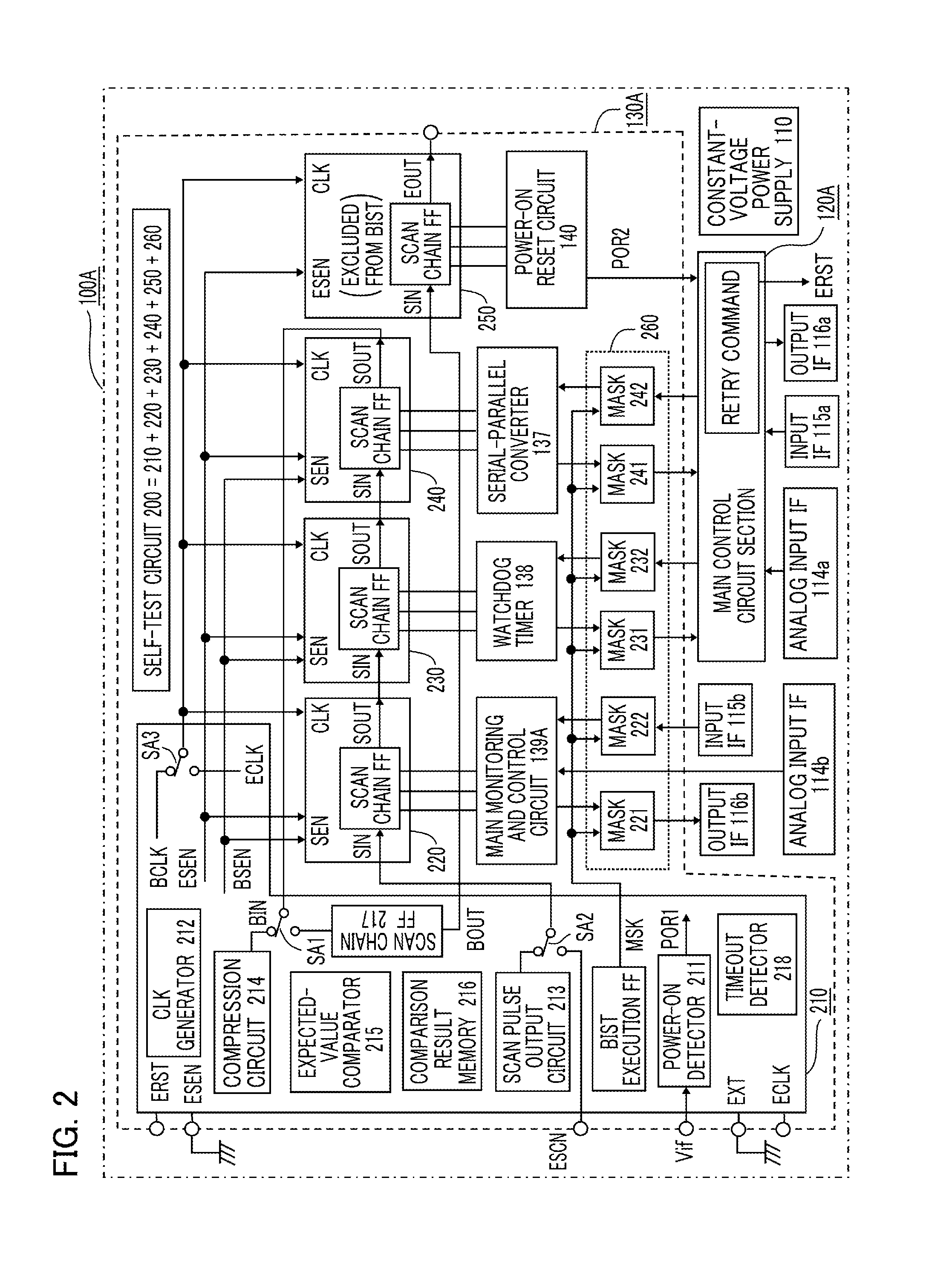

[0035]The configuration of an electronic control unit having integrated circuit elements, according to an embodiment 1 of the present invention will be described in detail below with reference to FIG. 1 showing an overall configuration diagram of the electronic control unit. Referring to FIG. 1, an electronic control unit 100A is mainly constituted with late-described components: a constant-voltage power supply circuit 110; a main control circuit section that is a first integrated circuit element 120A (hereinafter, may also be referred to as a main control circuit section 120A); and a monitoring and control circuit section that is a second integrated circuit element 130A (hereinafter, may also be referred to as a monitoring and control circuit section 130A). The electronic control unit 100A is applied with a main power supply voltage Vb from an external power supply 101, which is an vehicle-mounted battery for example, through an output contact 102a of a power supply relay, and also...

embodiment 2

[0089]The configuration of an electronic control unit 100B according to an embodiment 2 of the present invention will be described in detail below focusing an differences from that in FIG. 1, with reference to FIG. 7 showing an overall configuration diagram of the electronic control unit. Major differences between FIG. 1 and FIG. 7 are that an integrated circuit element subject to a self-test is a main control circuit section 120B and scan chain circuits outside the self-test are therefore changed; furthermore, the self-test is performed immediately after completion of the operation and a retry operation is therefore executed by a build-in self-test control block (BIST control block). Referring to FIG. 7, the electronic control unit 100B is mainly constituted with the above-described constant-voltage power supply circuit 110; the main control circuit section 120B that is the first integrated circuit element; and a monitoring and control circuit section 130B that is the second integr...

embodiment 3

[0128]The configuration of an electronic control unit 100C according to an embodiment 3 of the present invention will be described in detail below focusing on differences from that in FIG. 1, with reference to FIG. 11 showing an overall configuration diagram of the electronic control unit. Major differences between FIG. 1 and FIG. 11 are that an integrated circuit element subject to a self-test is a main control circuit section 120C; a monitoring and control circuit section does not jointly used for the main control circuit section 120C; and scan chain circuits outside the self-test are therefore changed. Note that the self-test is performed immediately before start of the operation as with embodiment 1 and a retry operation for the self-test is therefore commanded from a microprocessor immediately after boot-up. Referring to FIG. 11, the electronic control unit 100C is mainly constituted with the above-described constant-voltage power supply circuit 110; a main control circuit sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com