Method of manufacturing continuous sucker rod

a technology manufacturing methods, applied in the direction of manufacturing tools, soldering devices,auxillary welding devices, etc., can solve the problems of increased costs associated with continuous sucker rods, increased production costs, and inability to meet the requirements of continuous sucker rods, so as to reduce space and time requirements, reduce capital costs, and eliminate heavy equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

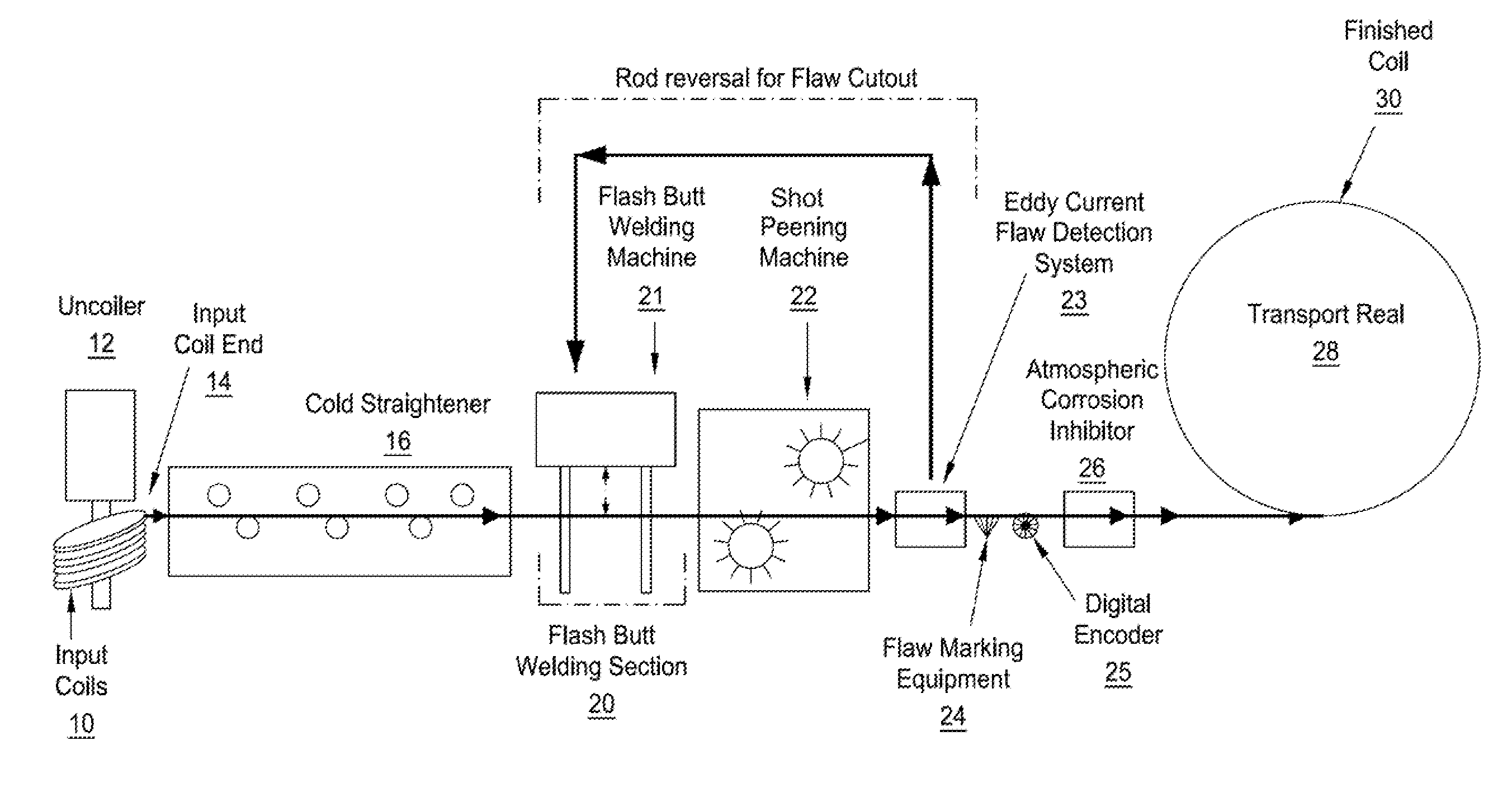

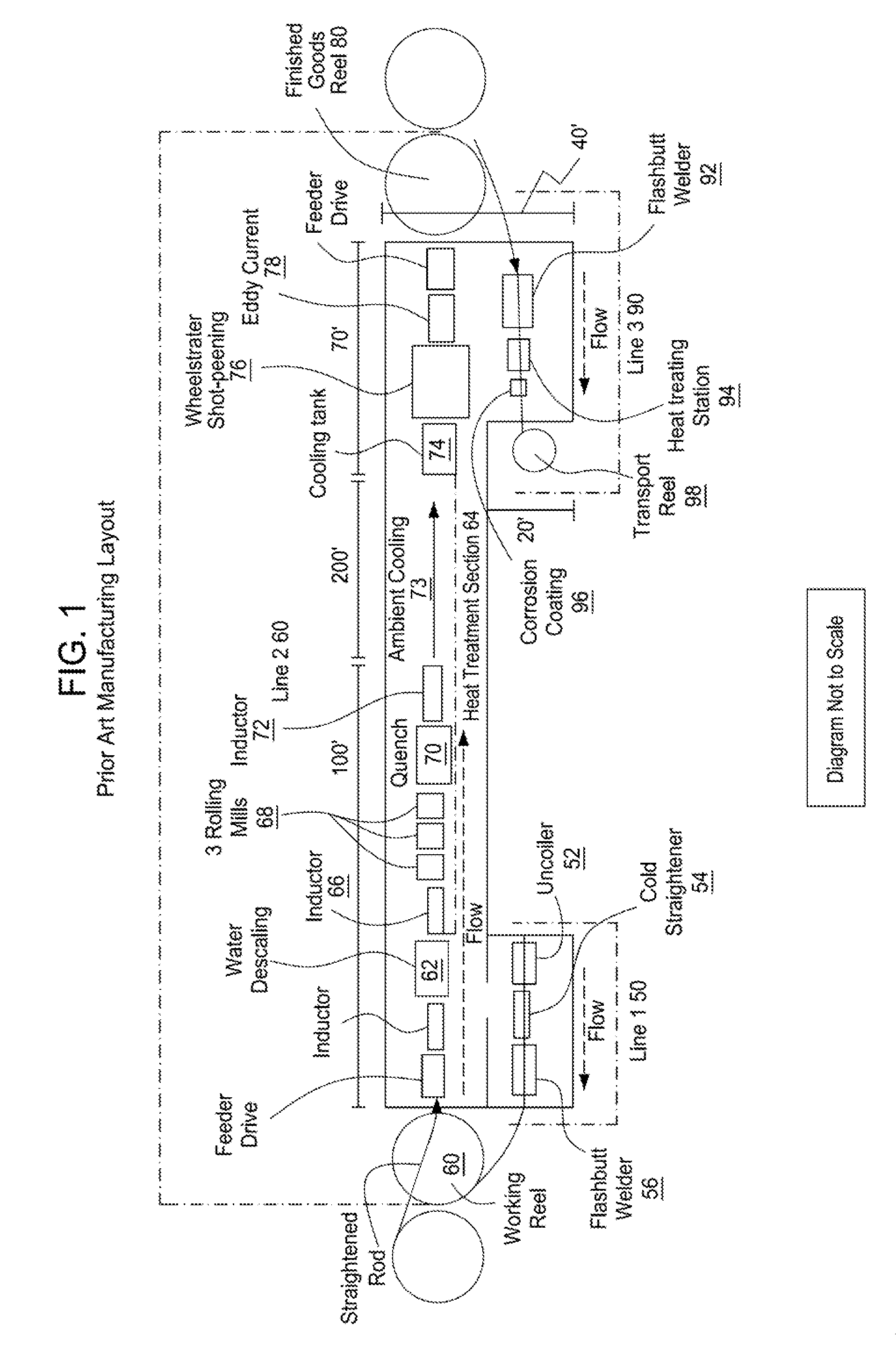

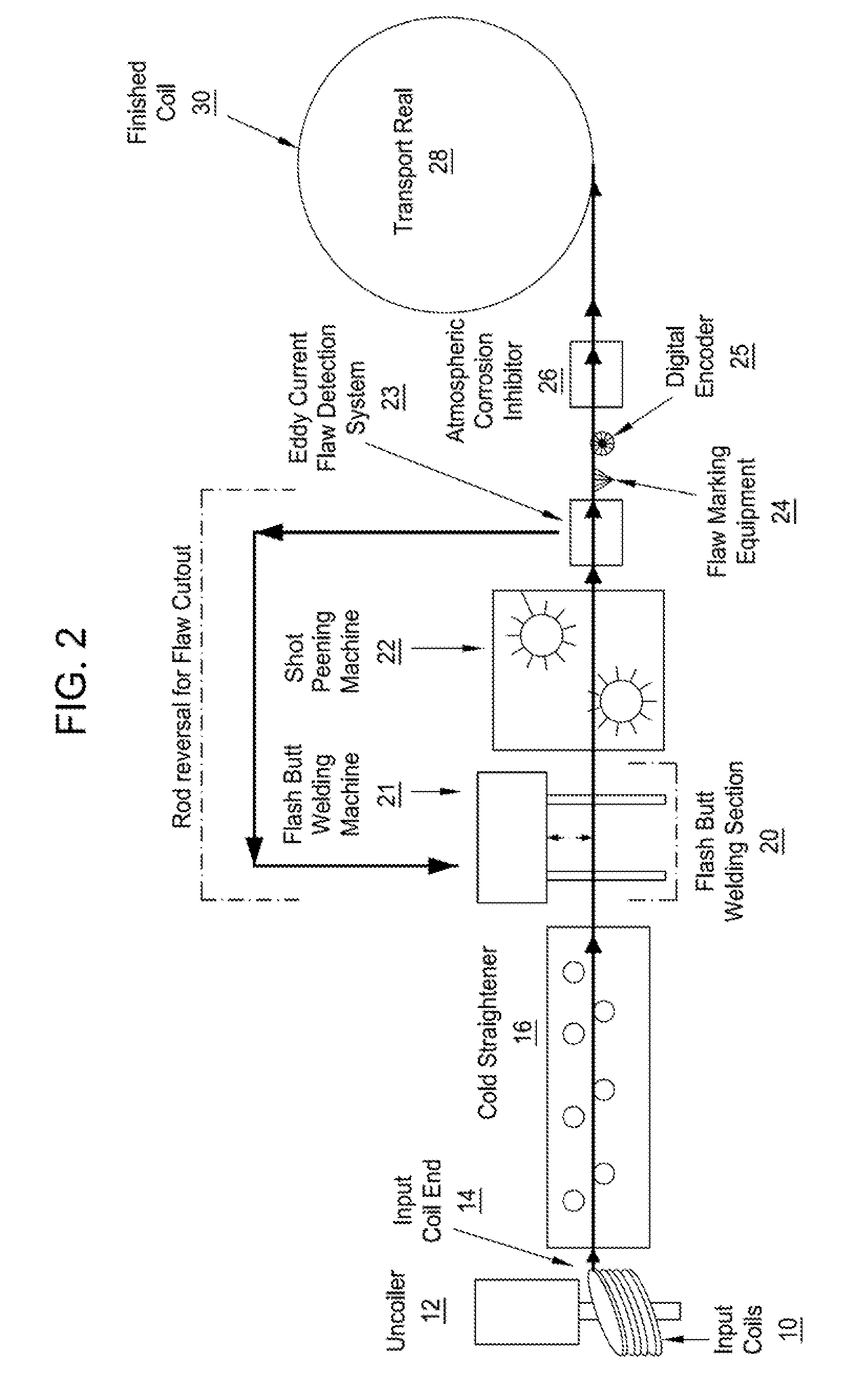

[0024]The prior art method shown in FIG. 1 is an illustration of the steps involved in a prior art method where the steel from the steel mill is selected without specifying a requirement of a uniform tensile strength along and among the input coils to be used to produce the continuous sucker rod. Referring now to FIG. 1, there are three lines in this method—Line 1 (50), Line 2 (60) and Line 3 (90).

[0025]On Line 1, the steel coil from the steel mill (not shown) is uncoiled by an uncoiler (52), then straightened by a straightener (54) and then passed through a first flash-butt welding section (56). Welding in the first flash-butt welding section (56) is applied only to the ends of the steel mill coils to fuse one end of one coil to the end of the next coil to form one continuous elongated piece of steel. After passing through the flash-butt section, the steel is transferred to a large working reel (58) to be held until production on Line 2 is initiated.

[0026]On Line 2 (60), the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com