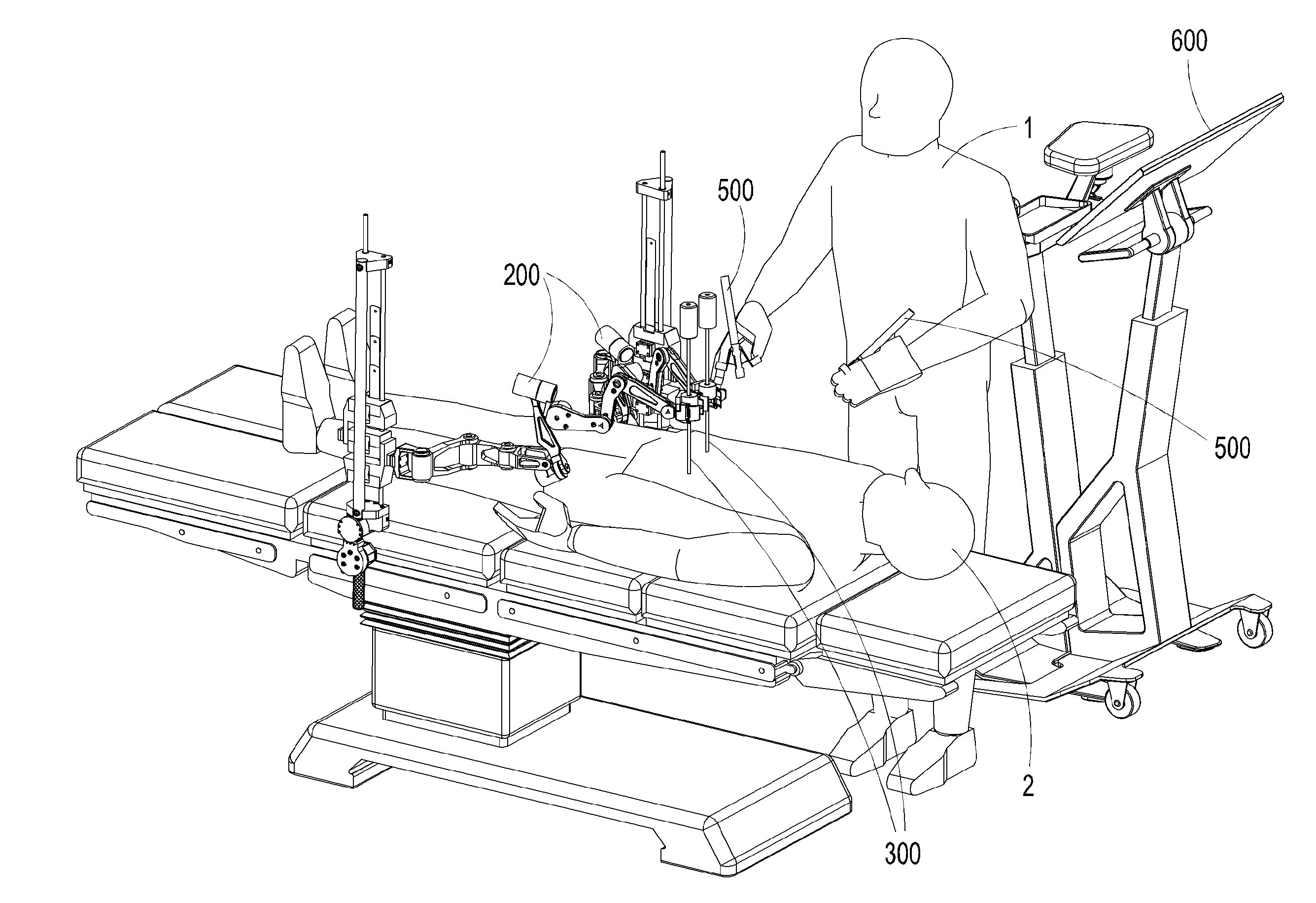

Hyperdexterous surgical system

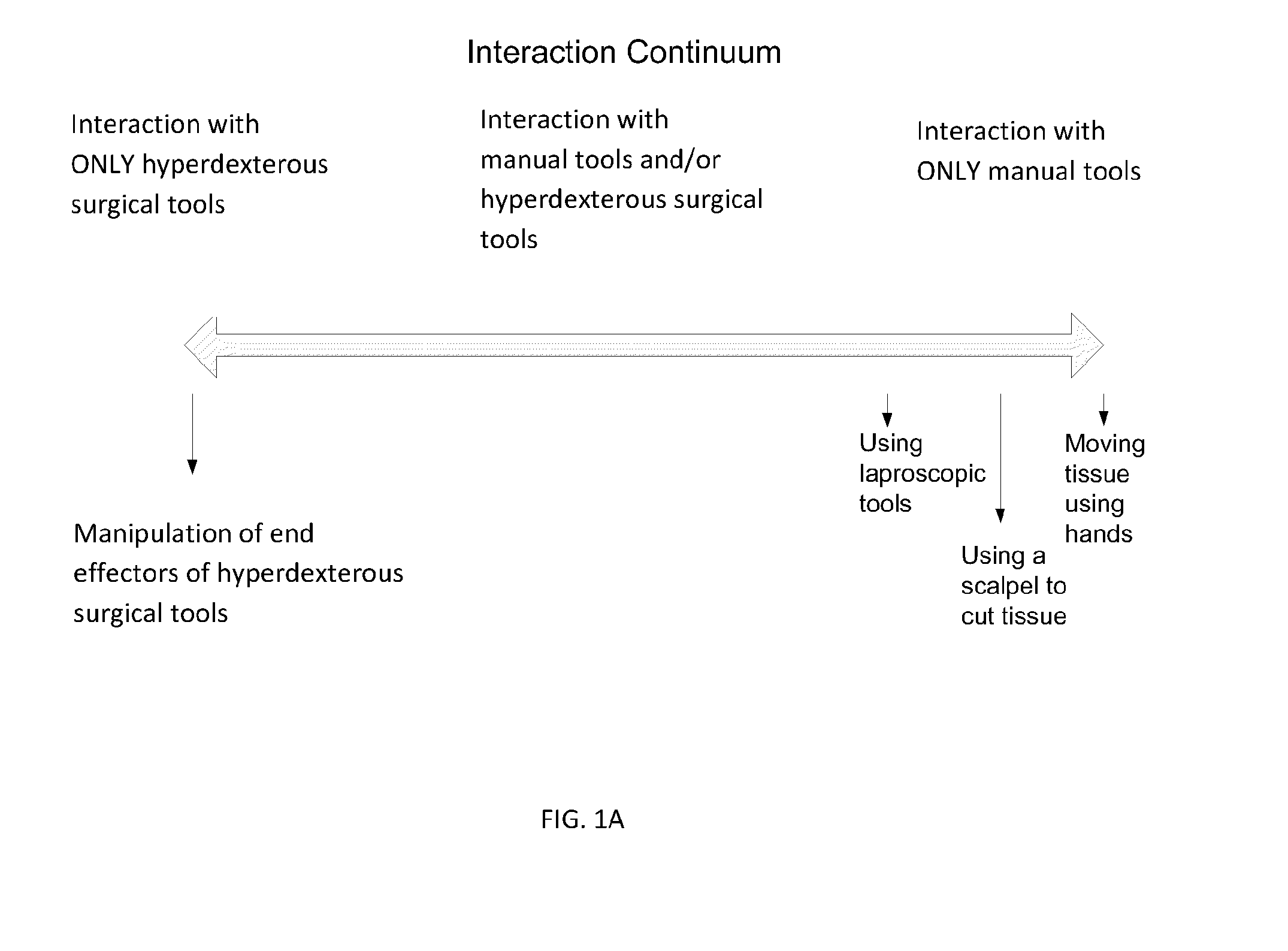

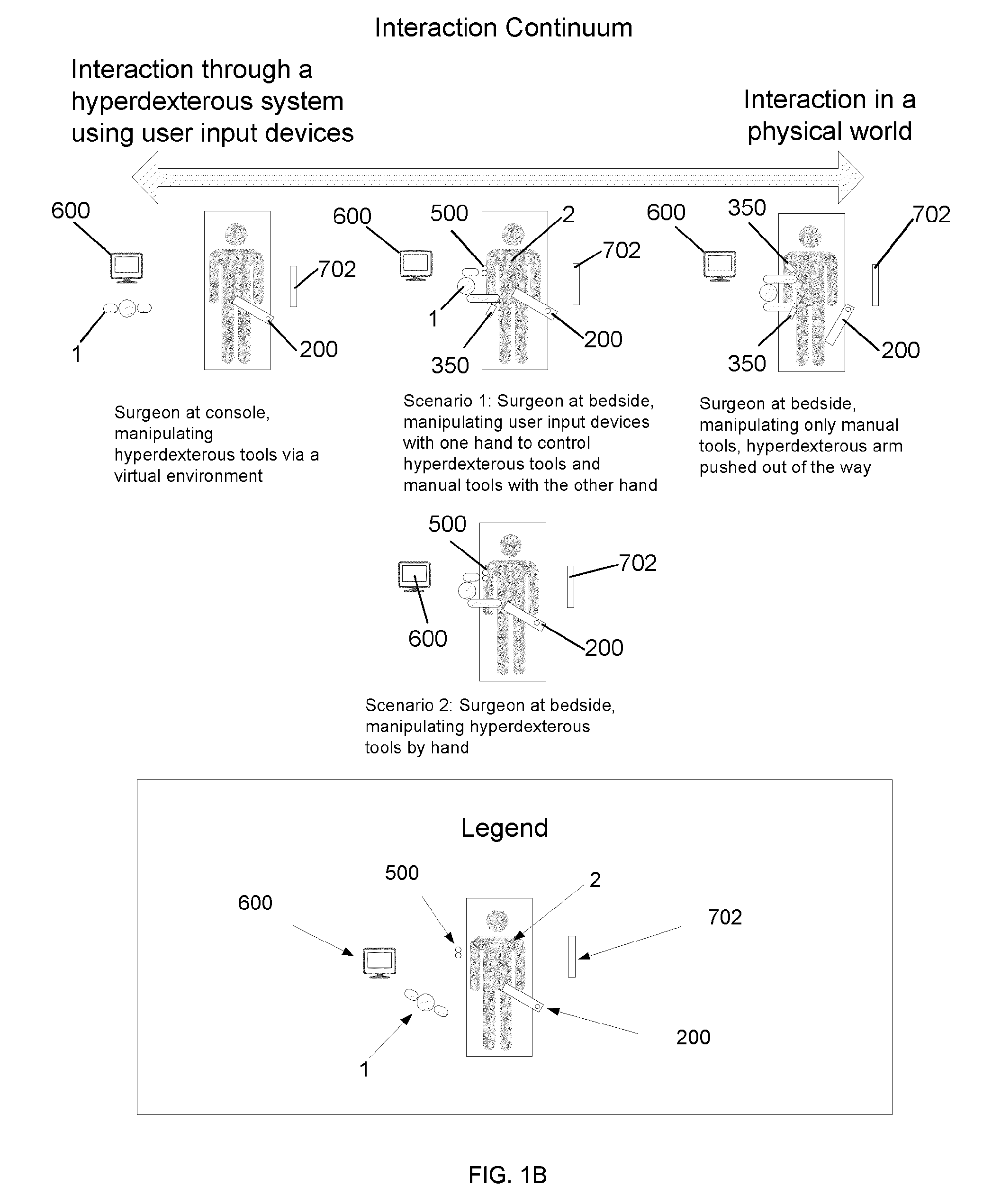

a surgical system and hyperdexter technology, applied in the field of surgical systems and methods, can solve the problems of robotic tools, not being well-suited for other surgical tasks, and the motion of the distal end of the tool relative to the proximal end of the tool may not be natural,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

an embodiment

of a Surgical Method

[0343]In some embodiments, one or more manual tools 350 are used in conjunction with one or more hyperdexterous surgical tools 300 in the same work space. An example of a manual tool 350 is a stapler 354, see FIG. 39. The stapler 354 may be used in conjunction with the hyperdexterous surgical tool 300. The workflow when using both types of tools in a colon resection surgical procedure is shown in FIG. 39, which shows a method 5. FIG. 39 illustrates one method of using a hyperdexterous surgical tool 300 and a manual tool 350. The method relates to holding the colon in a particular position and placing a staple line across the colon. The system includes a first grasper 312, a second grasper 314, a camera 304, and a stapler 354. The system includes two input devices 500, a first controller 516 and a second controller 518.

[0344]In step 10, the operator 1 may position the camera 304 by using any of the input devices 500. In some embodiments, the operator 1 connects an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com