Mechanical press system and method of removing salt using the same

a mechanical press and salt technology, applied in the field of systems and methods for removing salts, can solve the problems of increasing the risk of accidental release of such materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

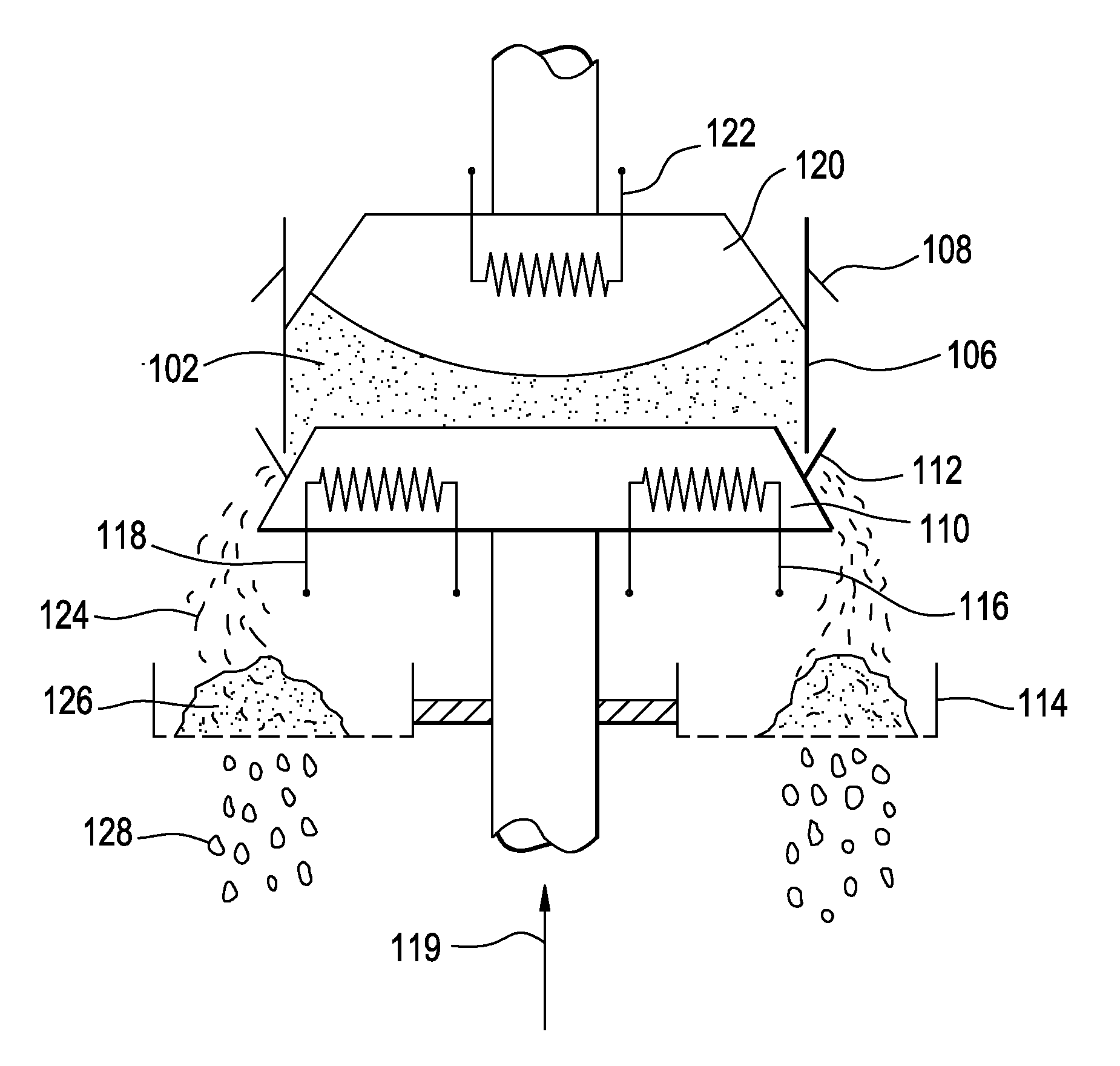

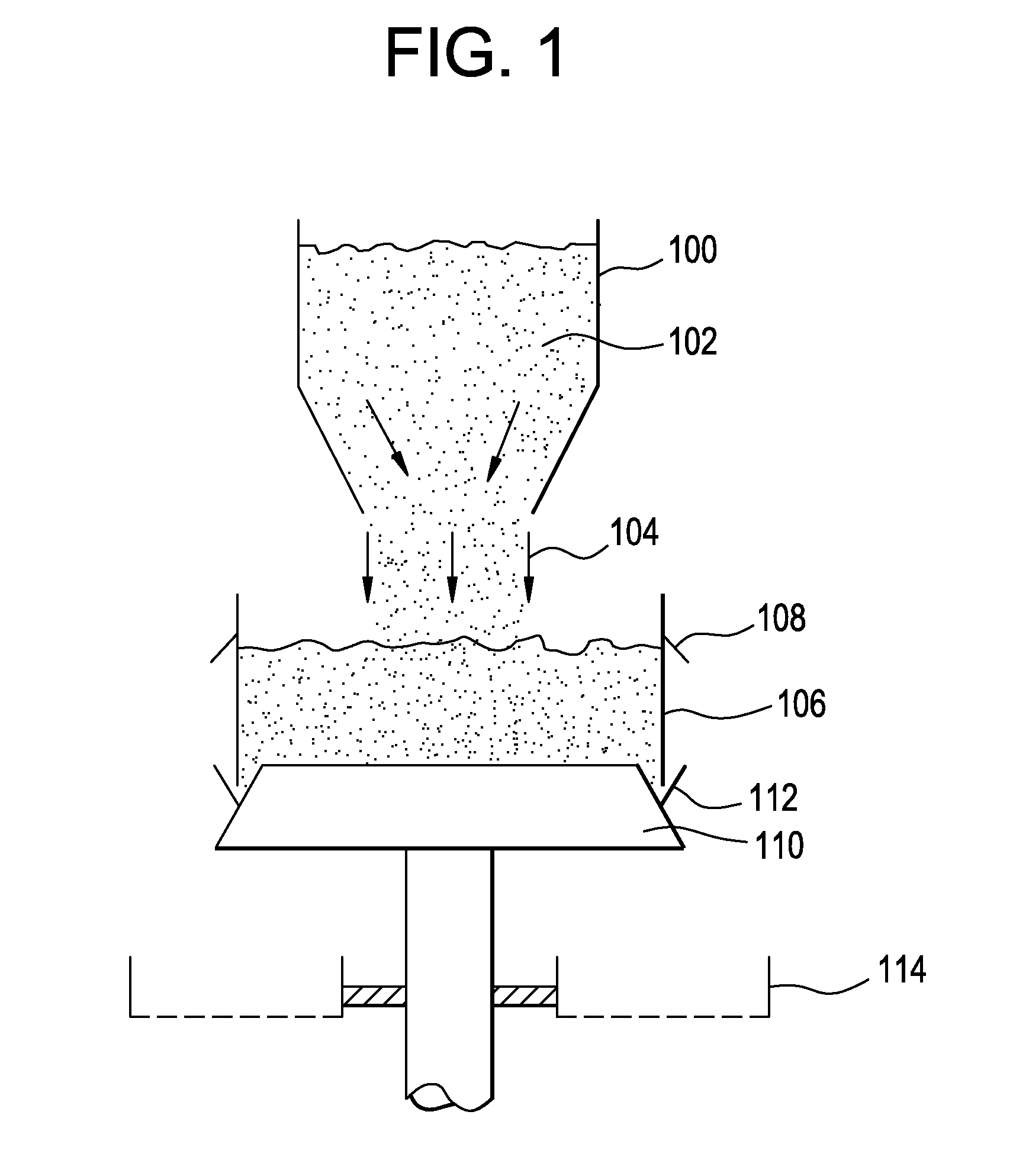

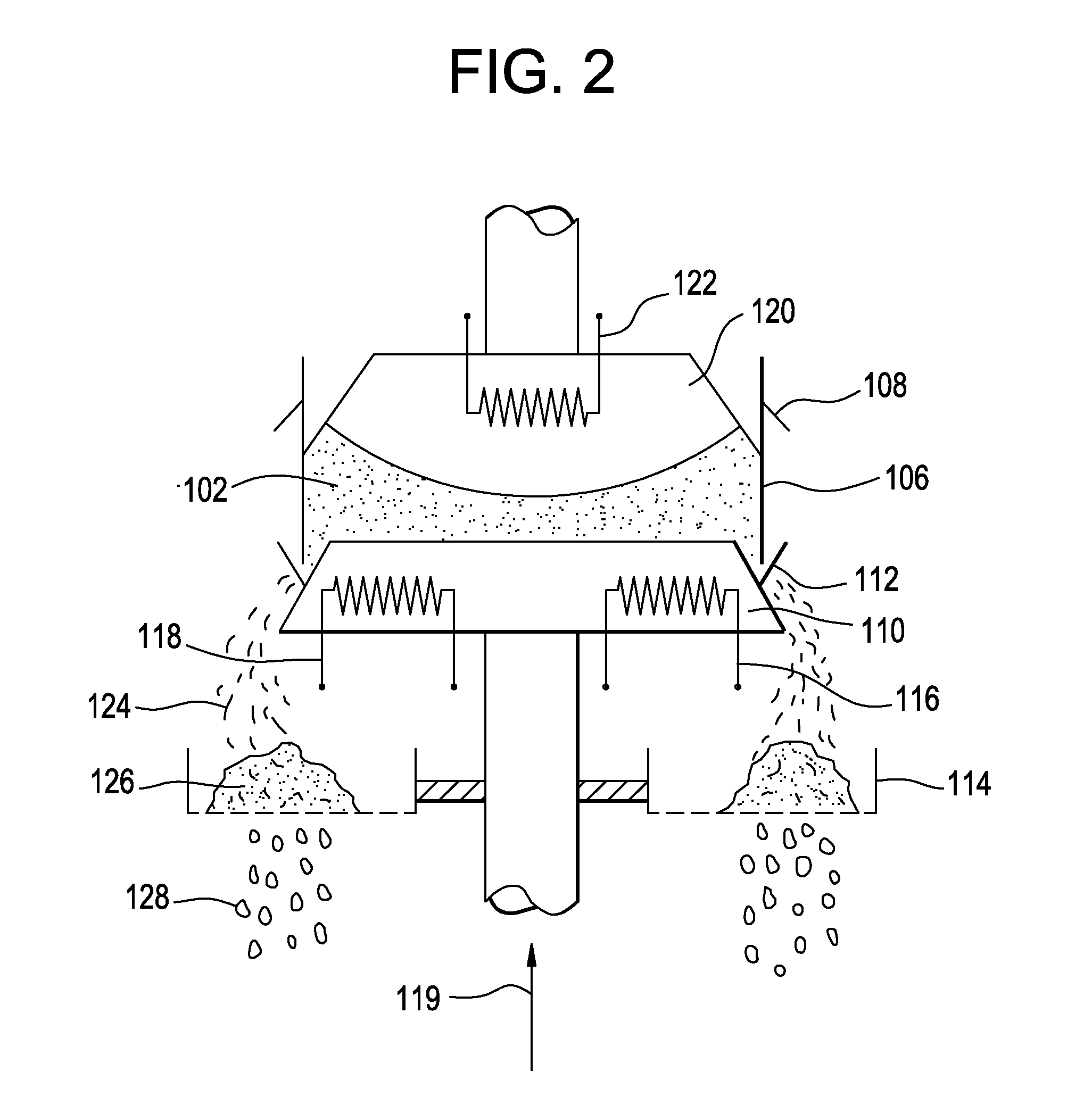

[0006]A mechanical press system may include an upper press body including a curved bottom portion and an upper lip portion surrounding the curved bottom portion; a first heater within the upper press body; a lower press body aligned below the upper press body, the lower press body including a top portion and a lower lip portion surrounding the top portion, the upper press body and lower press body configured to come together during a compression state and configured to move apart during a decompression state; a second heater within the lower press body; and a containment band configured to rest on the lower lip portion of the lower press body and to surround the upper lip portion of the upper press body during the compression state and configured to separate from the upper press body and the lower press body during the decompression state.

[0007]A method of removing salt from a dendritic mixture may include loading the dendritic mixture into a mechanical press system, the dendritic m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

| Metallic bond | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com