Glass container with roll-on closure

a glass container and roll-on technology, applied in the field of glass containers, can solve the problems of inability to maintain the pressure of the container to keep the beverage adequately carbonated, beverage soon loses carbonation and goes “flat”, and is difficult to adequately clean and sterilize. to achieve the effect of maximizing beverage consumption characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

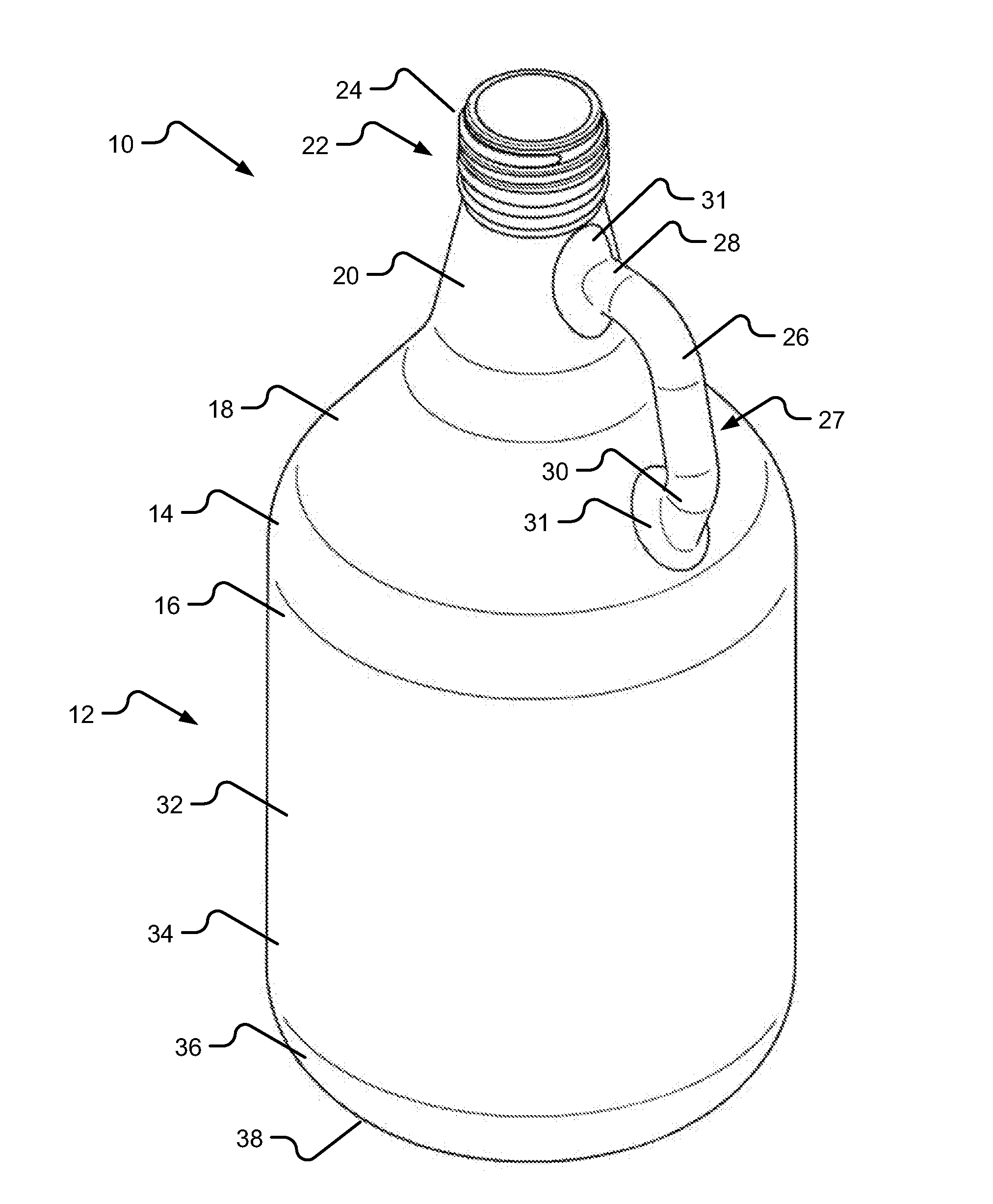

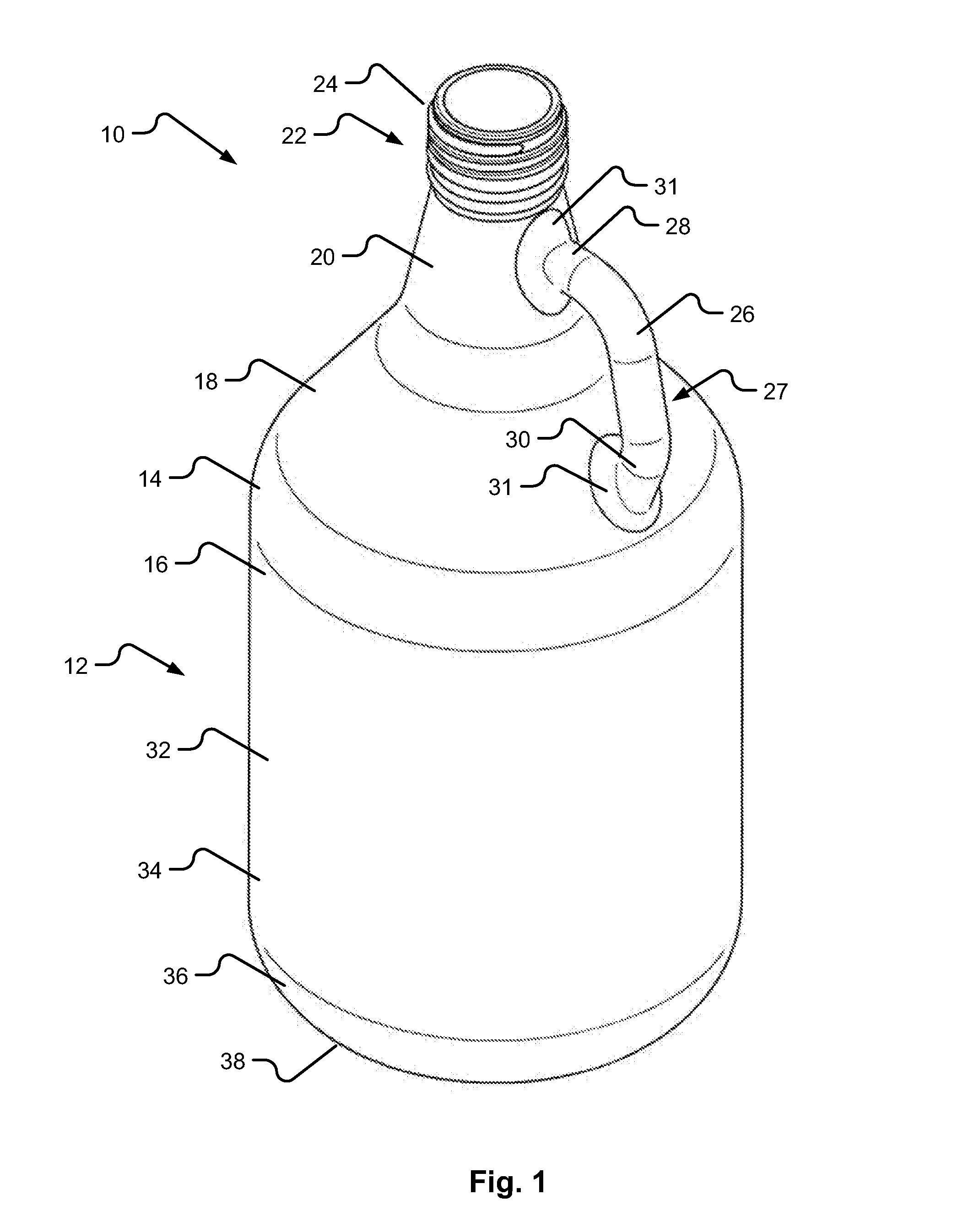

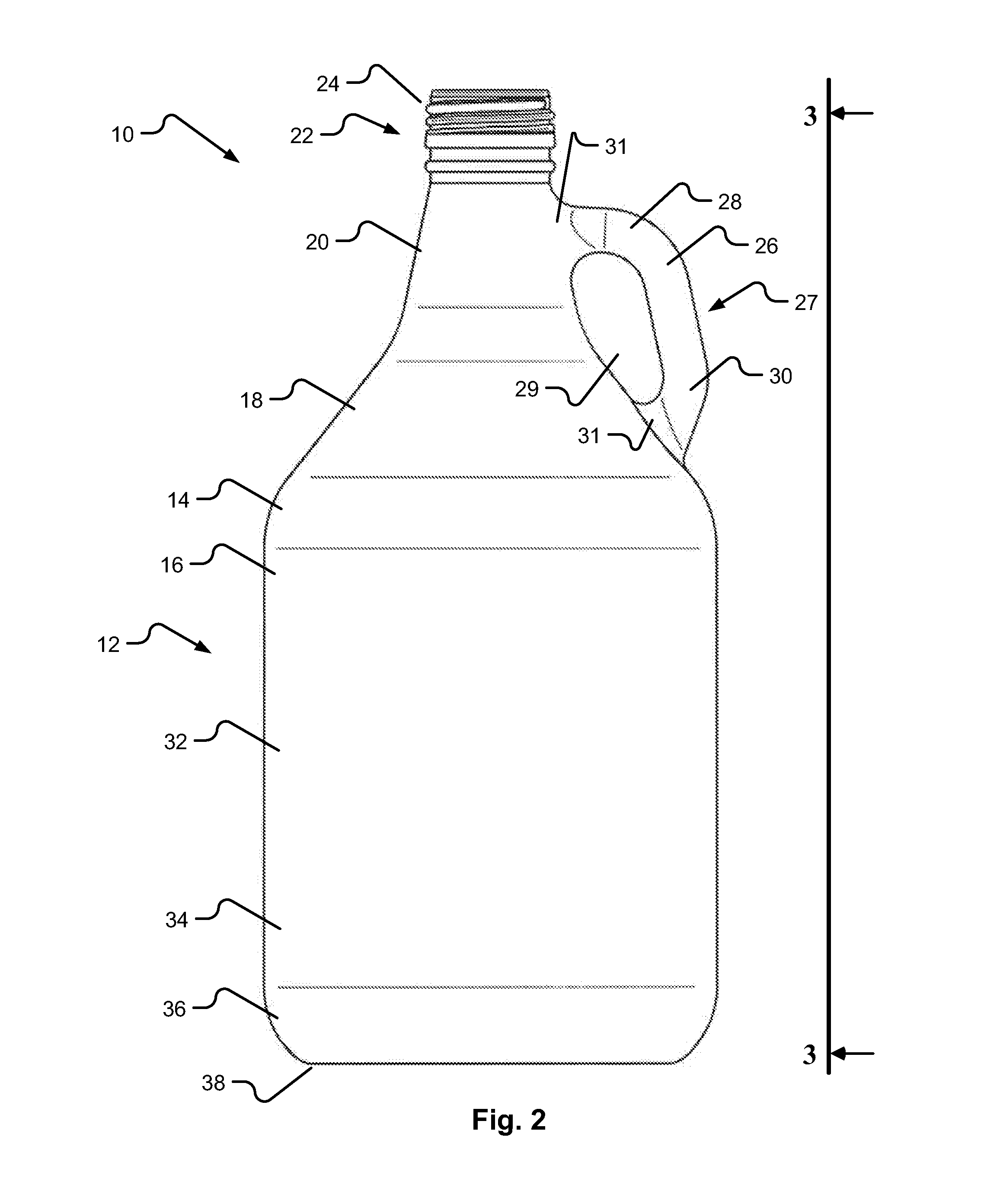

[0024]Referring to FIGS. 1-3, a container 10 of the present invention shown. The container 10 can be referred to as a growler, a container sized for holding a bulk volume of a beverage, and especially adapted for holding carbonated beverages such as beer. The container has a sidewall 12, a shoulder 14 disposed above an upper portion 16 of the sidewall, a converging portion 18, and a neck 20 disposed above the converging portion 18. The upper end of the container, also referred to as the finish 22, has threads 24 formed thereon. An integral handle 26 is provided, the handle 26 having an upper end 28 that attaches to the neck 20 at a base 31, and a lower end 30 that attaches to the converging portion 18 at base 31. The bases 31 of the upper and lower ends 28, 30 of the handle 26 are enlarged as shown which contributes to the increased break strength, as discussed below. The loop 27 of the handle is adequately sized for carrying, and the loop 27 creates an arcuate shaped opening 29 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com