Low viscosity engine oil with superior engine wear protection

a low viscosity, engine oil technology, applied in the direction of lubricant composition, liquid carbonaceous fuels, additives, etc., can solve the problems of increased engine wear, inability to provide acceptable passenger vehicle diesel engine durability performance, and diesel engines are more prone to filter plugging, so as to improve fuel economy and improve anti-wear performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

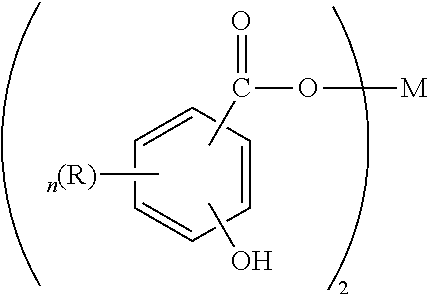

Image

Examples

examples

[0076]Lubricating oil compositions according to the invention were prepared using a blend of PAO, ester and Group III base oils.

[0077]In addition to a metal detergent, viscosity index improver, and ZDDP, the composition included borated and non-borated ashless dispersant, phenolic and aminic antioxidants, defoamant, pour point depressant, friction modifier and seal swelling agent.

[0078]Representative formulations are given in Table 2.

TABLE 2Invention Invention Comp.Comp.Comp.Comp.Comp.FormulationEx 1Ex 2Ex. 3Ex. 4Ex. 5Ex. 6Ex. 7Viscosity Grade0W-200W-200W-300W-205W-305W-305W-30Component, wt %Ca Salicylate and / or Mg2.21.82.252.333.523.522.33Sulfonate Detergent (total)Ca Salicylate Detergent2.21.32.251.53.523.521.5Mg Sulfonate Detergent0.50.830.83Friction Modifier (total)0.150.150.150.480.730.770.4Friction Modifier 0.150.150.150.10.180.220.1(Organo-molybdenum)Friction Modifier 0.380.550.550.3(ashless organic)Viscosity Index Improver(solid polymer content)Styrene-isoprene0.120.12block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com