Processing unit and method for separating hydrocarbons from feedstock material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The invention may be better understood by reference to the following detailed description, taken in conjunction with the figures. Various embodiments of the invention relate to a system for eliminating biofilm on a surface. Other configurations and variants will be apparent to those skilled in the art from the teachings herein.

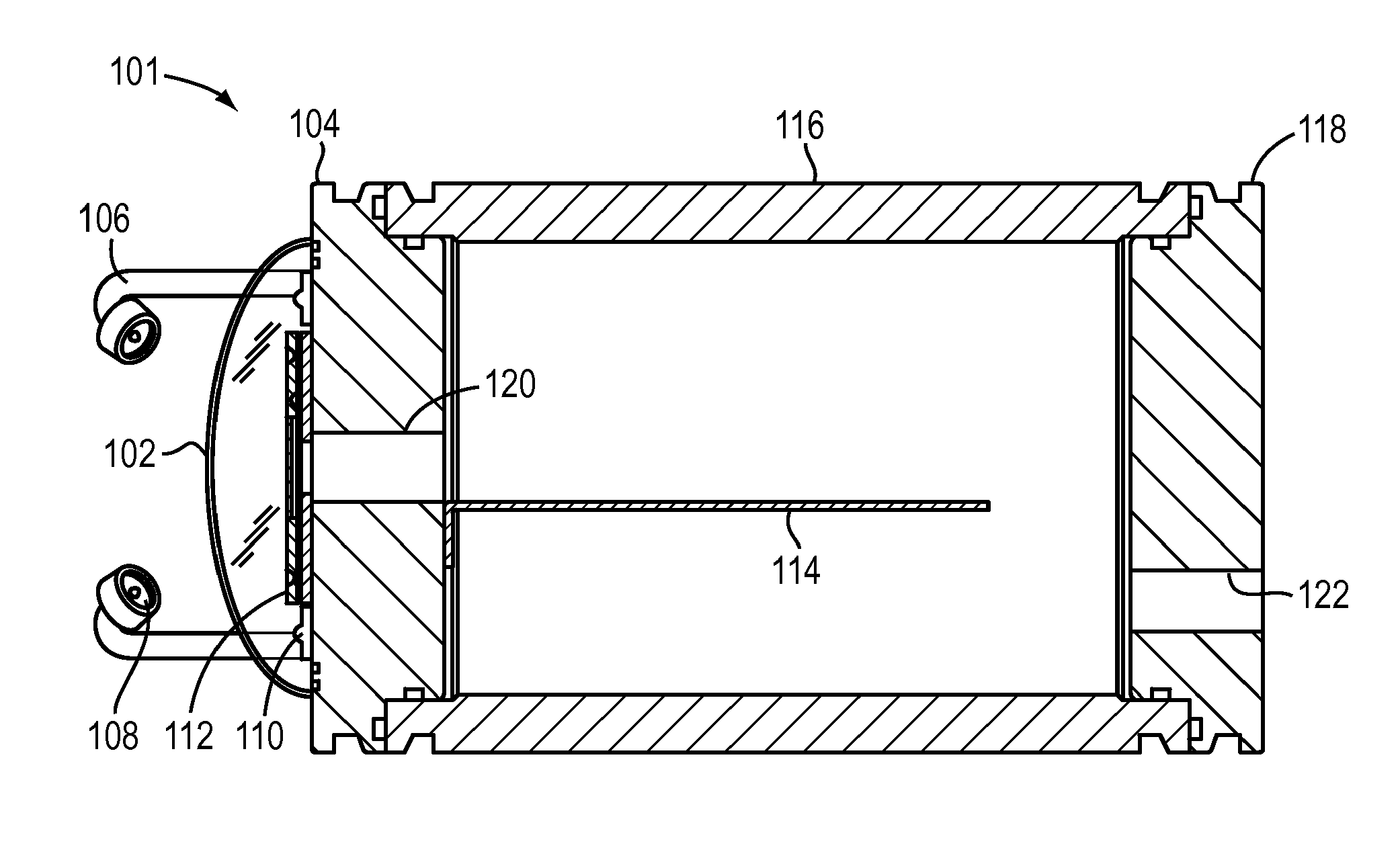

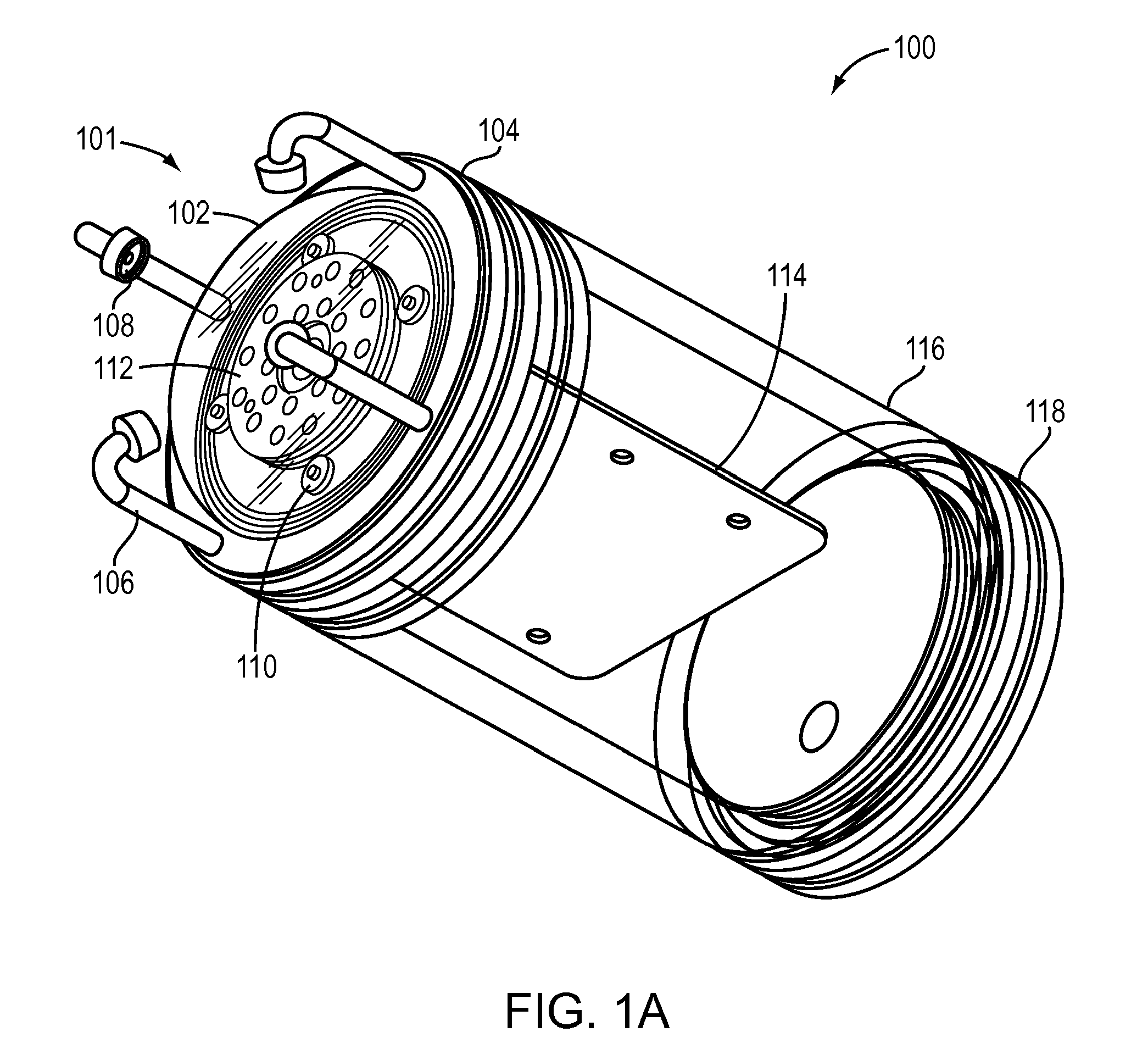

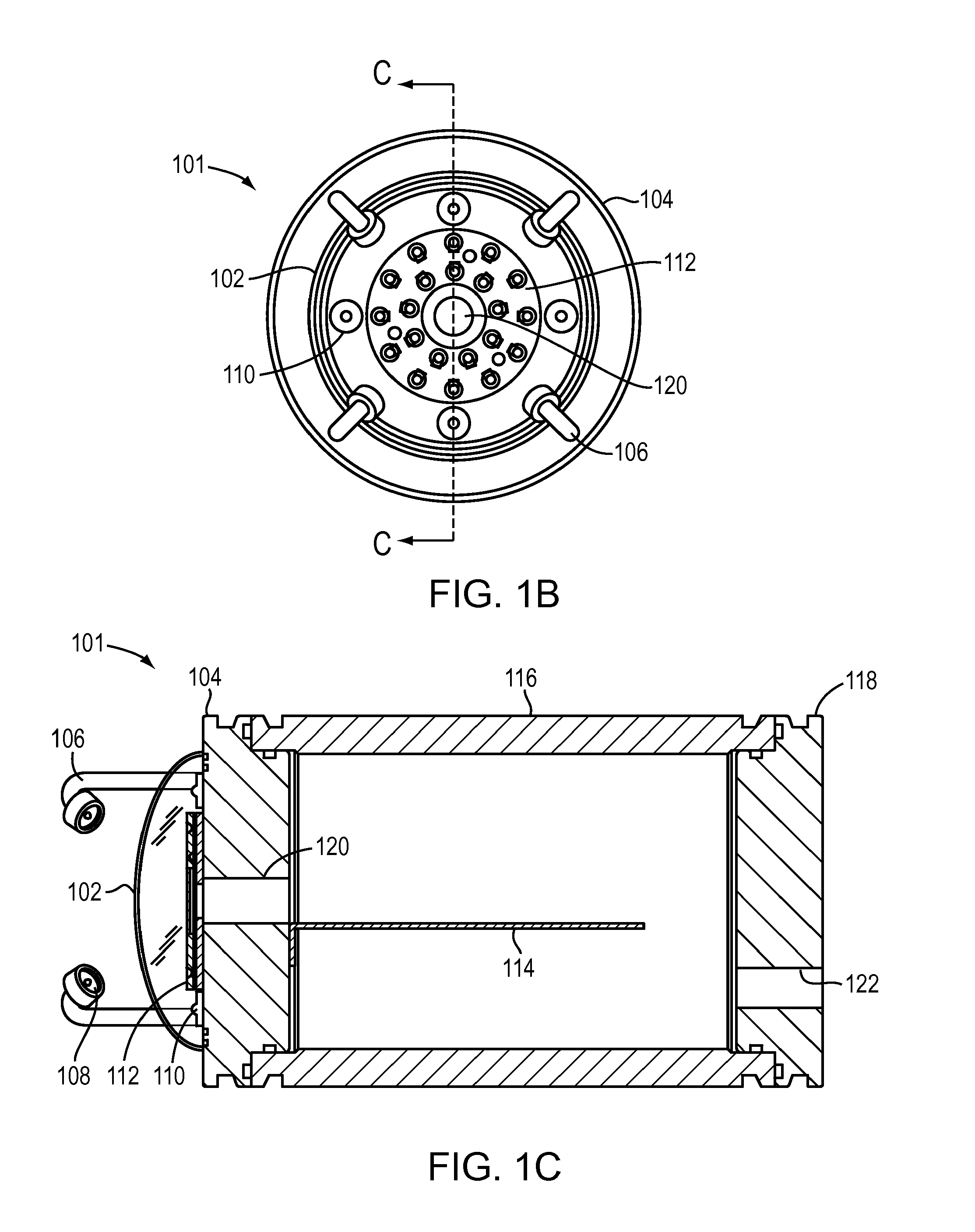

[0020]FIG. 1A depicts an optical modem (or transmitter assembly) 100 with a system 101 for reducing fouling of a surface of an optically transparent element 102 in a marine environment. The outer surface of the optically transparent element may be in contact with marine fluid, making this surface particularly vulnerable to developing biofilm that supports larger organism bio-fouling. The system 101 may be configured to remove / prevent the formation of biofilm. The optically transparent element 102 allows for the transmission of light therethrough, enabling communications and sensors reliant on optics to operate within the interior of the optical modem 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com