Re-lined pipe technique for wear mitigation in slurry transport pipeline

a technology of slurry transport pipeline and relining, which is applied in the direction of pipe elements, mechanical equipment, coatings, etc., can solve the problems of inability to monitor the wear rate and status of lined pipes, inability to perform ultrasonic non-destructive examination approaches to detect lining wear (wall thickness), and inability to do so, so as to achieve high abrasion resistance and wear resistance, the effect of high degree of abrasion resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

FIG. 1

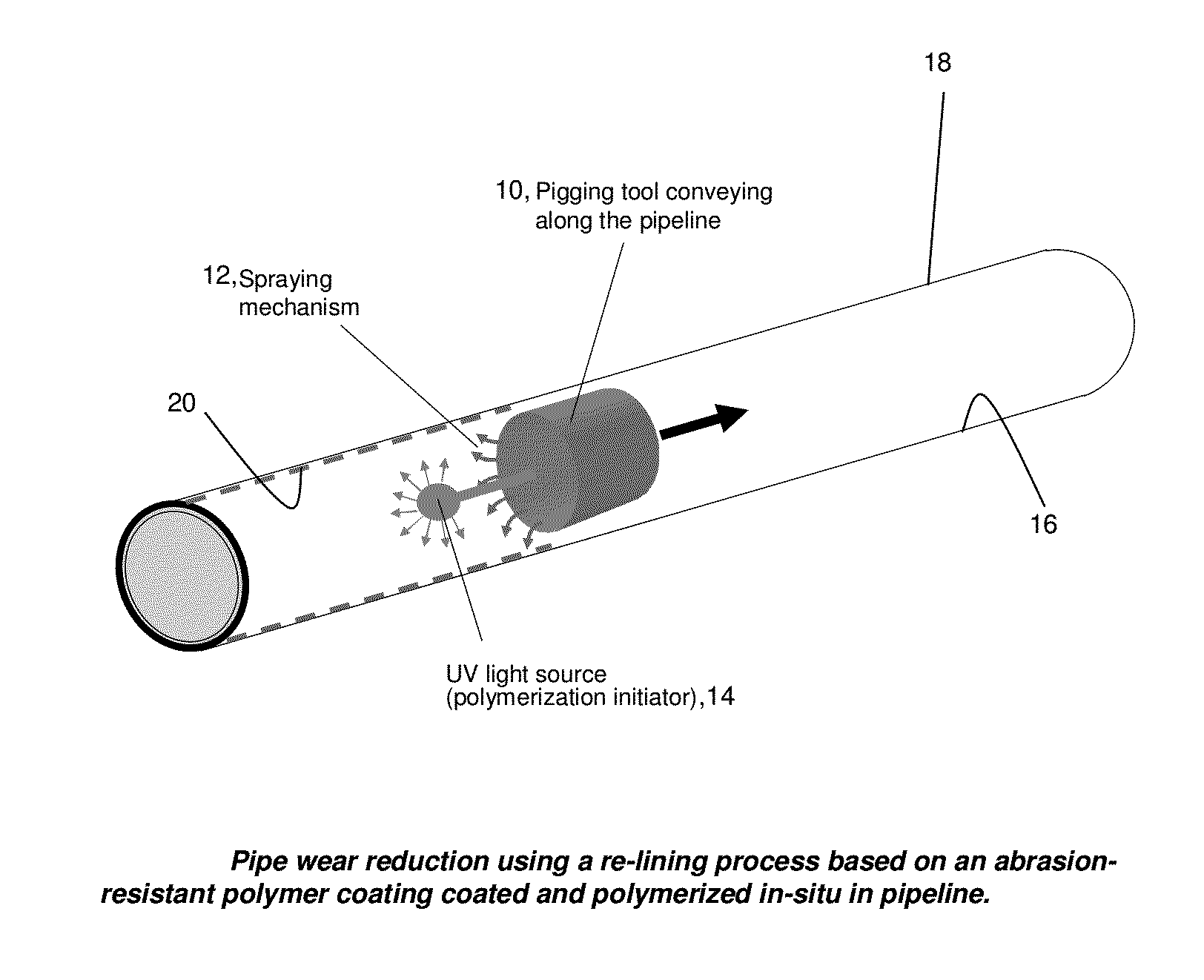

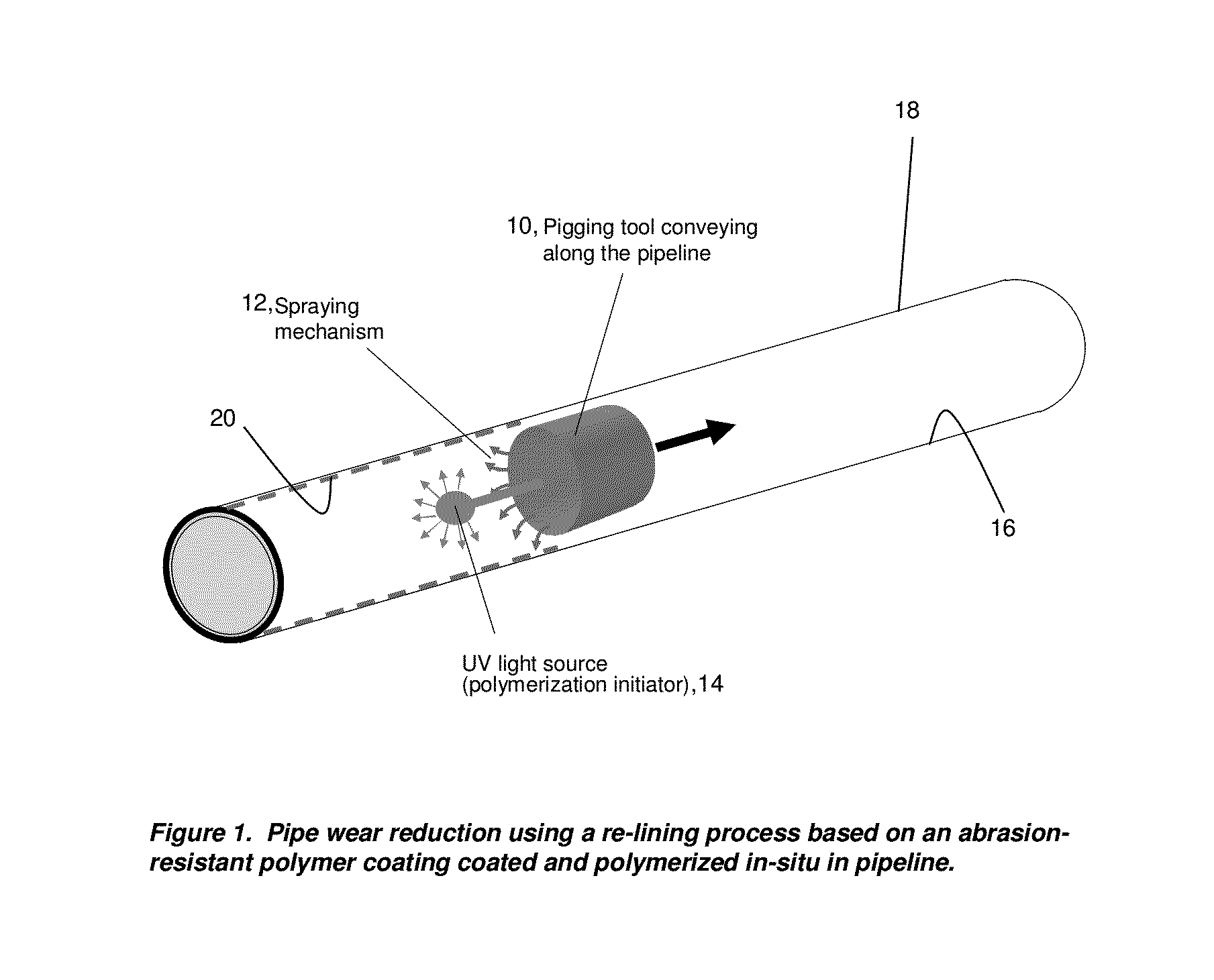

[0029]In the technique according to the present invention, a so-called “sacrificial” coating may be applied to normal high wear pipes, e.g., such as mild steel (carbon steel) pipes, to provide an “abrasion barrier.” This coating may be applied using a pipe “pigging tool” that traverses the pipeline and applies the coating compound and polymerizes the coating as it passes down the pipe. FIG. 1 shows the concept and principle of operation of the technique, according to some embodiments of the present invention. The pipeline, used for example in coarse tailings transport, may be cleaned using an initial pass by a pigging tool, then a tool designed to spray-coat the inner surface of the pipe with the monomer coating, then polymerize the coating via a UV irradiation, according to the present invention. The subsequent coating, while possibly even being thin, is designed to have sufficient wear resistance to allow the pipeline to be operated, e.g., for at least 6 months, and / or to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wear resistance | aaaaa | aaaaa |

| Mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com