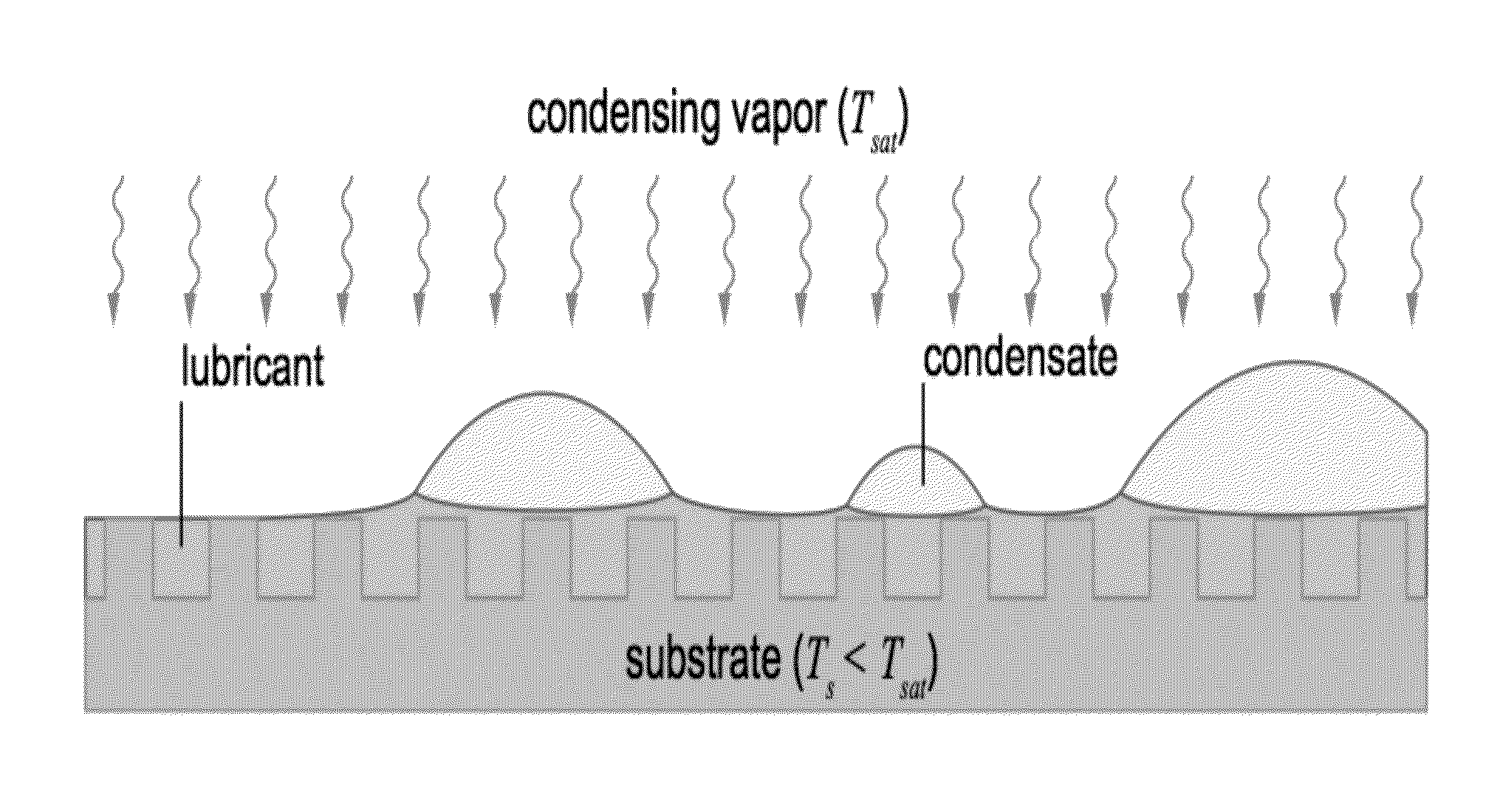

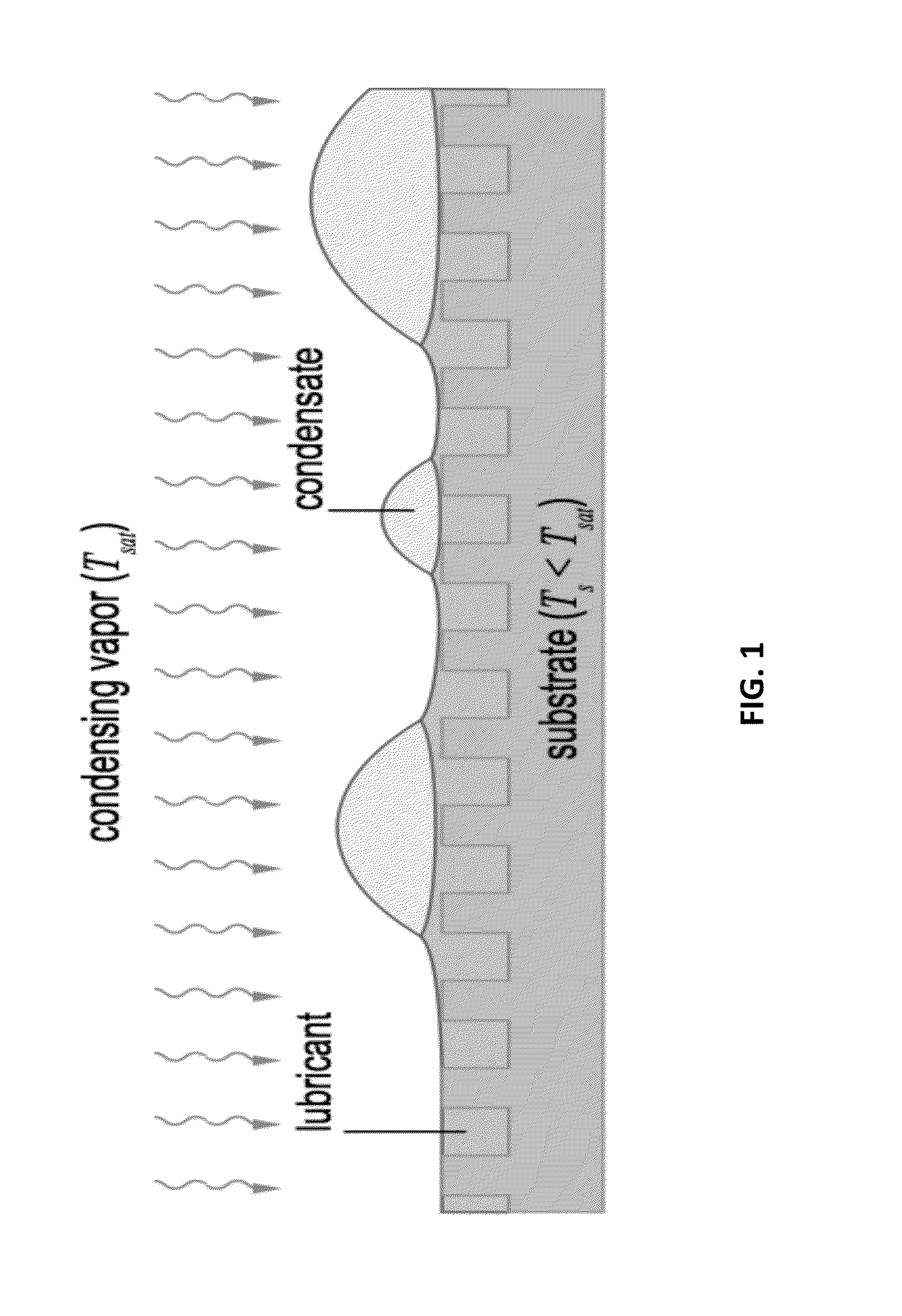

Controlled liquid/solid mobility using external fields on lubricant-impregnated surfaces

a technology of lubricant impregnated surfaces and external fields, which is applied in the direction of solar heat collectors with working fluids, magnetic materials, solar thermal energy generation, etc., can solve the problems of dramatic reduction in panel efficiency, optimize energy transfer, and improve droplet slippage. , the effect of facilitating the shedding of both moisture and dus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Materials and Methods

[0104]Ferrotec EMG 901 ferrofluid was used for ferrofluid, which includes nominal magnetite particle diameter of 10 nanometers at concentration of 11.8% volume. The ferrofluid has a saturation magnetization of 660 Gauss and a viscosity of 8 cP at 27° C.

[0105]K&J Magnetics 3 mm radius cylindrical neodymium permanent magnet (Grade N52) were used as permanent magnets

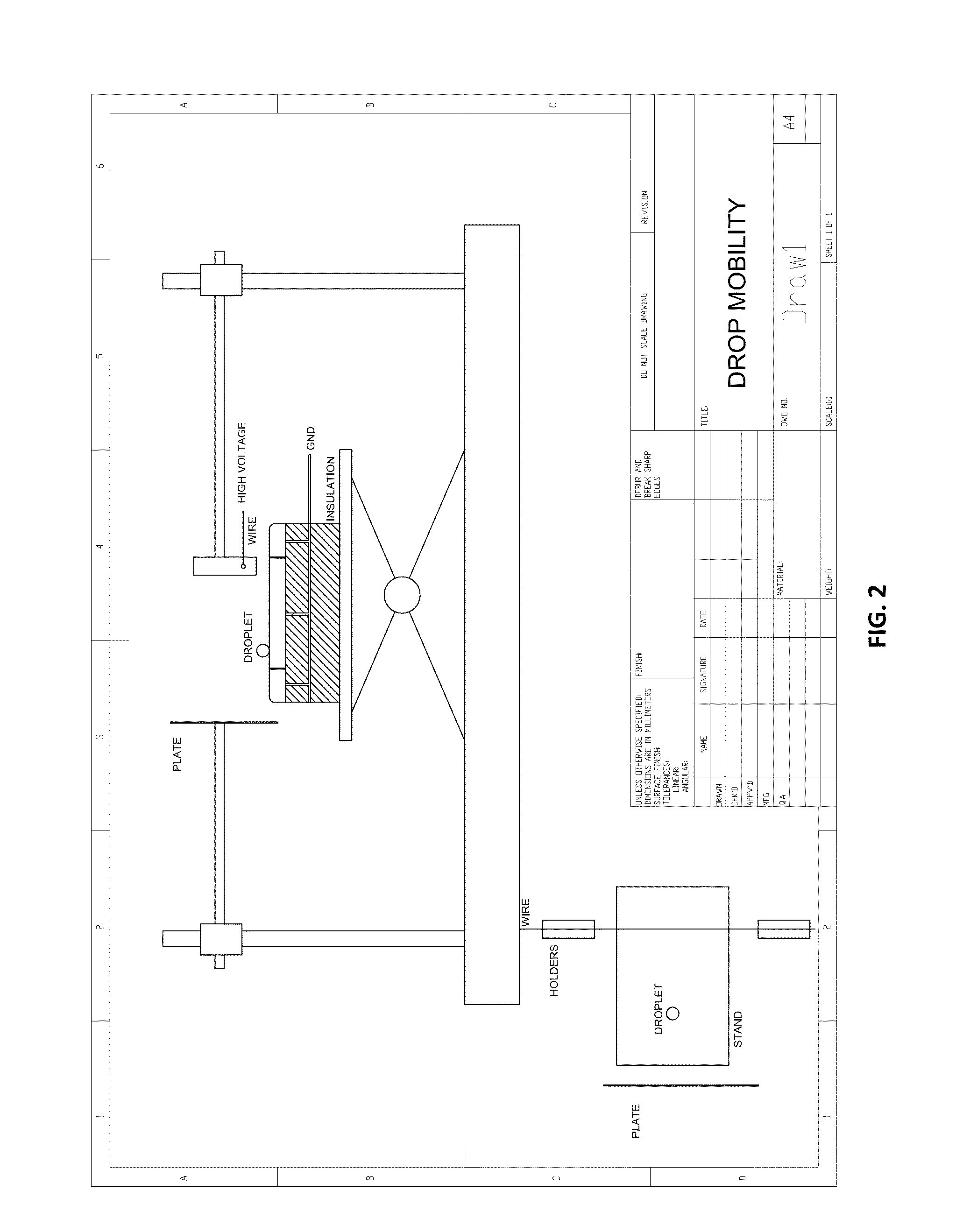

Electric Field Experiments

[0106]For both FIGS. 5 and 6, the samples that were used were identical. Silicon wafers were textured using typical clean-room photolithography and RIE (reactive-ion etching). Once the samples were textured, they were coated with a low surface energy silane (octadecyltrichlorosilane (OTS)) which rendered the surface hydrophobic and preferentially wetted by oil. OTS exhibits an advancing water contact angle of 110±4° on a smooth surface. The samples were impregnated using a careful dip coating technique at a controlled rate such that there was no excess oil. The oil used in both...

PUM

| Property | Measurement | Unit |

|---|---|---|

| vapor pressure | aaaaa | aaaaa |

| surface energies | aaaaa | aaaaa |

| vapor pressures | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com