Applicator with separately produced and mounted bristle plates

a technology of bristle plates and applicators, which is applied in the field of cosmetics applicators, can solve the problems of increasing difficulty and entailing a large amount of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first complete exemplary embodiment

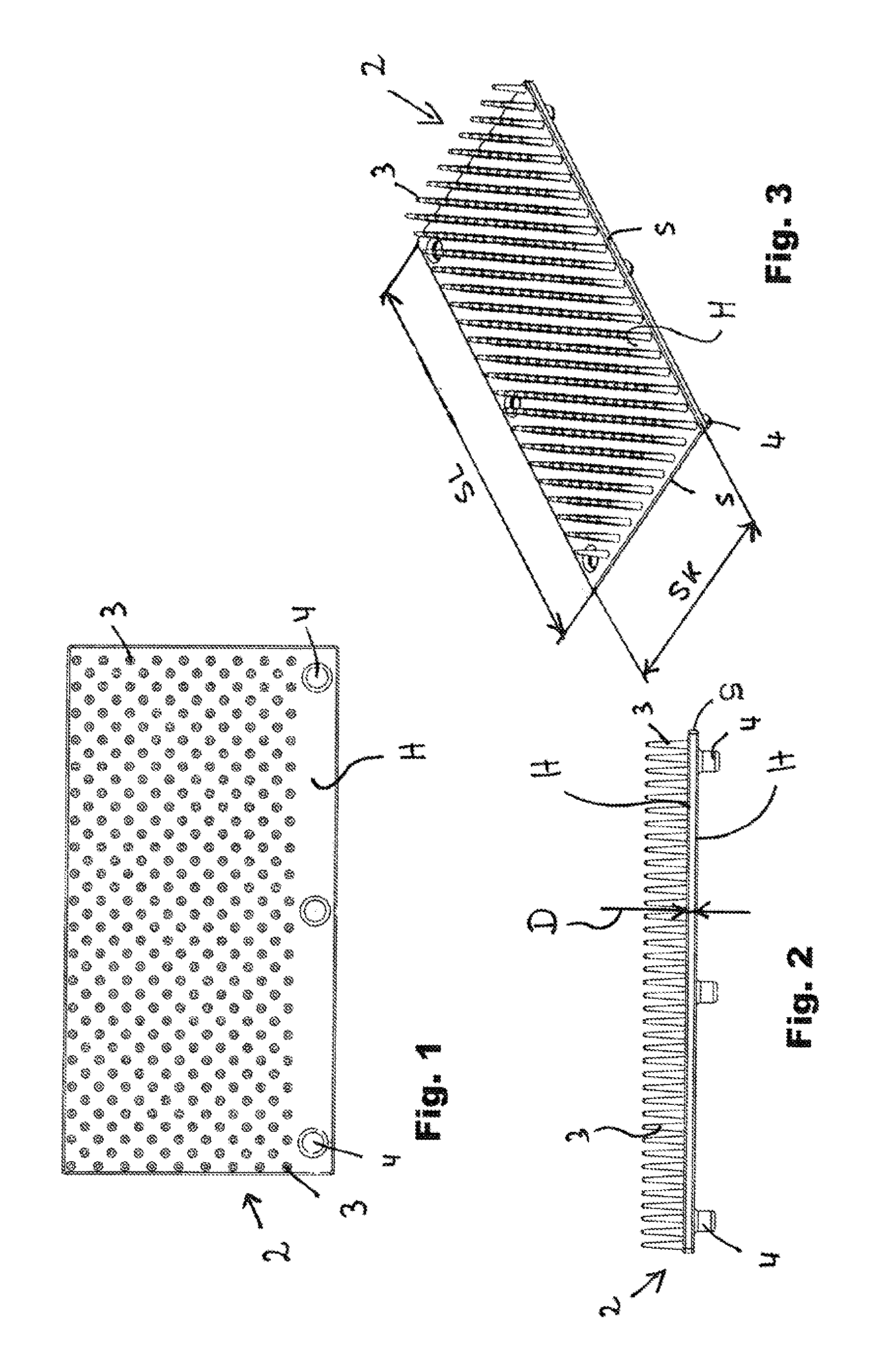

[0139]FIGS. 13 to 15 show a first complete exemplary embodiment that illustrates how the above-described finger-carrying plates 2 are used in order to produce an applicator 1, and in particular a cosmetics applicator.

[0140]Preferably, a finger-carrying plate 2 as is shown by FIG. 13 is used as the starting point, wherein, however, finger-carrying plates with a different design can also be used. In any case, the statements in the introduction pertaining to the finger-carrying plates apply mutatis mutandis.

[0141]Here, the finger-carrying plate 2 has a tongue-like shape, i.e. its long lateral edges SL are larger by at least the factor 4 than its short lateral edges SK.

[0142]The finger-carrying plate 2 is equipped with a field of fingers 3 in which the fingers respectively form rows of fingers aligned one behind the other in the longitudinal direction and in the transverse direction extending perpendicularly thereto. Here, the fingers are preferably all oriented parallel with regard to ...

second complete exemplary embodiment

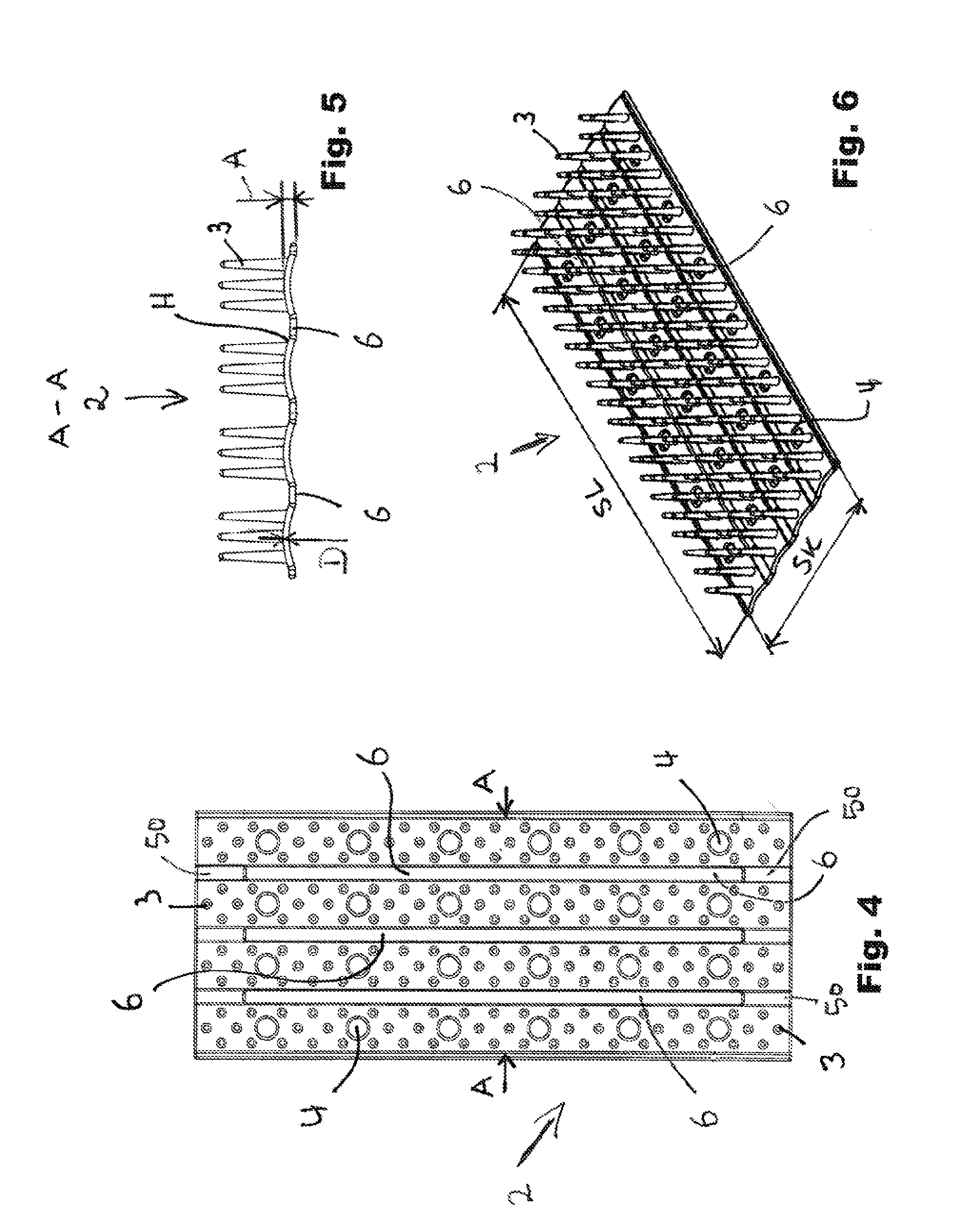

[0153]FIGS. 16 and 17 show a second complete exemplary embodiment of the invention.

[0154]A finger-carrying plate 2 as it is shown by FIG. 16 is used for this exemplary embodiment. In principle, this finger-carrying plate 2 corresponds to the finger-carrying plate already shown by FIG. 13, so that reference can be made to the explanations given there.

[0155]The only point to note is that the fingers are not arranged in lines in the longitudinal and transverse direction, but are distributed irregularly. However, they may also be arranged in lines also in this case, just like in the preceding exemplary embodiment. Conversely, the type of arrangement of the fingers here can of course also be chosen for the preceding exemplary embodiment.

[0156]FIG. 16 again shows the finger-carrying plate 2 in its first three-dimensional shape, which it assumes immediately after its production.

[0157]FIG. 17 shows the finished applicator 1.

[0158]In this case, an applicator core 8 is used again which may be...

third complete exemplary embodiment

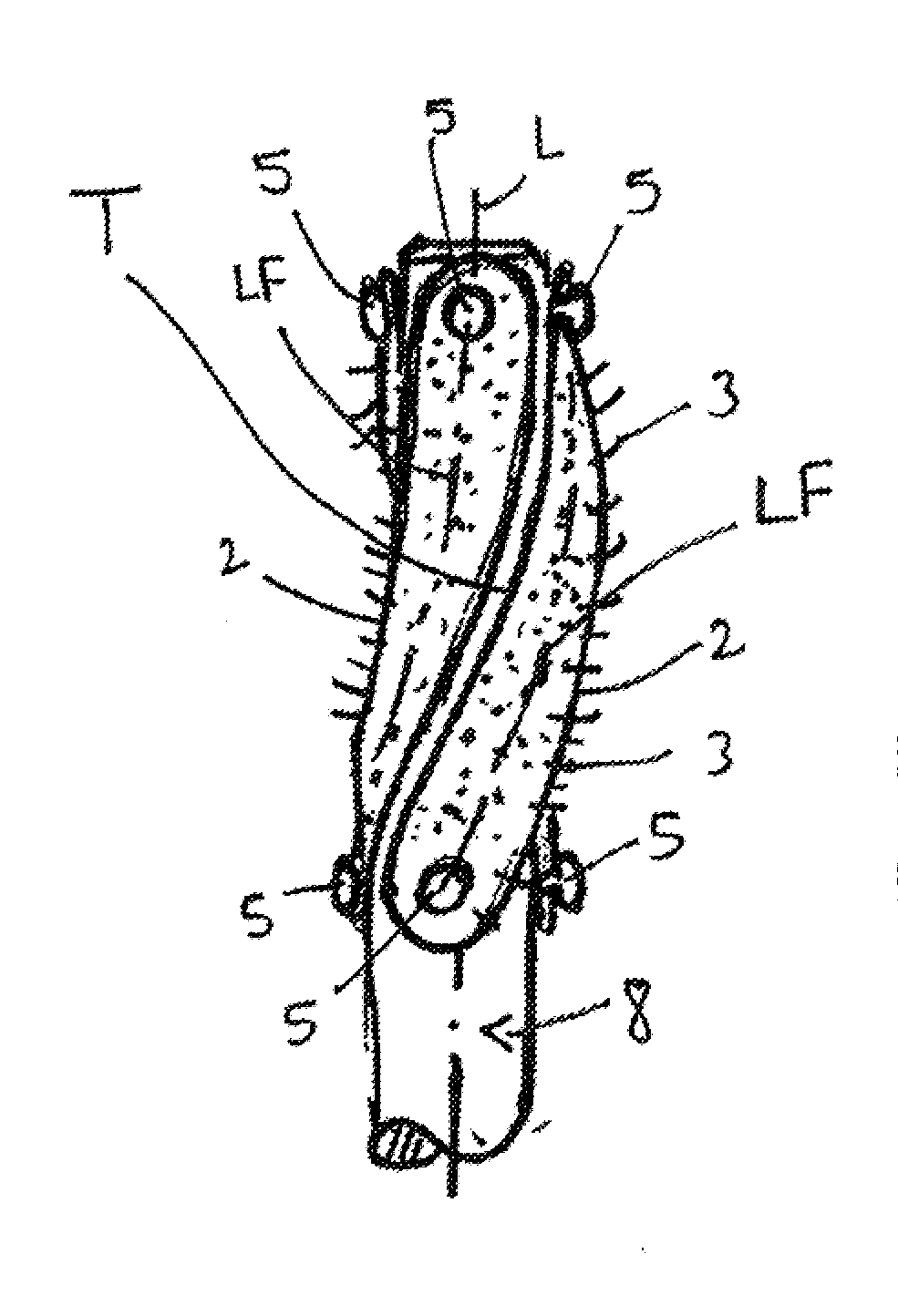

[0164]FIG. 18 shows a third complete exemplary embodiment.

[0165]Preferably, finger plates 2 as they have already been described above for the two preceding exemplary embodiments are again used within the context of this third complete exemplary embodiment; also see FIGS. 13 and 16. The statements there thus also apply here.

[0166]The special feature in this exemplary embodiment is that the longitudinal axes LF of the finger-carrying plates 2 here extend in a helical shape around the longitudinal axis L of the applicator core 8. In contrast to the similar exemplary embodiment already discussed above, each finger-carrying plate does not encircle the core part 9 completely, but extends only over an angle of ≦190 °, and better of ≦100 °, around the core part 9. Starting from their first three-dimensional shape shown in FIG. 16, the finger-carrying plates have been brought into a corresponding second three-dimensional shape.

[0167]Also in this case, fixation is effected by retaining organs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com