Larynx mask having a connector

a technology of larynx mask and connector, which is applied in the field of larynx mask, can solve the problems of insufficient aspiration protection, high cost, and insufficient work efficiency, and achieve the effect of reducing labor intensity, reducing labor intensity and simplifying the manufacture of larynx mask

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

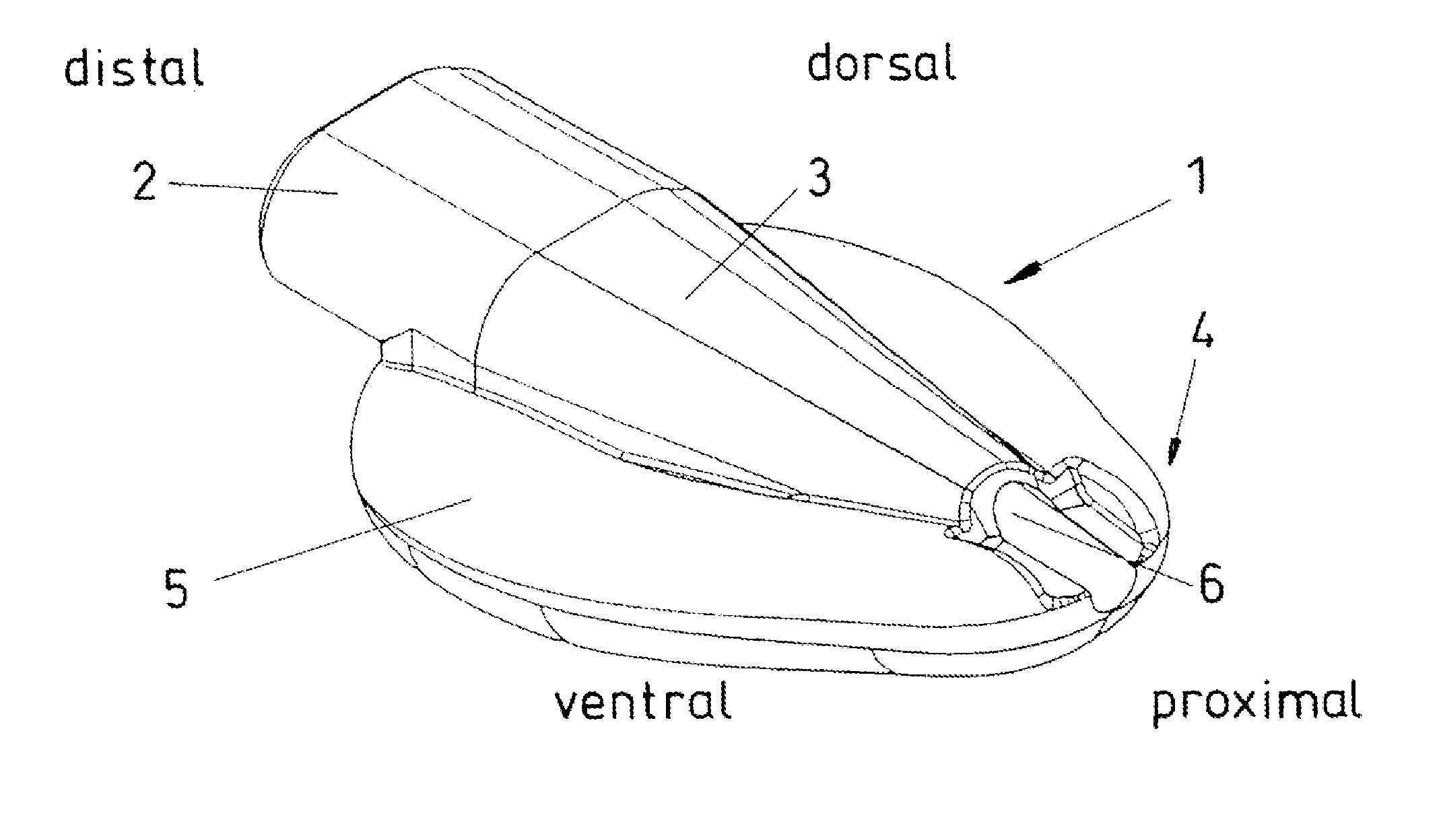

[0021]FIG. 1 shows the larynx mask which is denoted overall with 1. An insertion tube is attached to this larynx mask but is not shown in the drawing. However, for this a tube connecting connector 2 is used. This tube connecting connector 2 transits into a cover plate 3 and cuff 5 also formed thereon in one piece. The entire larynx mask 1 from the tube connecting connector 2 on the proximal end to the tip 4 on the distal end of the larynx mask is produced in one piece and accordingly all of the same synthetic material. In FIG. 1 the circumferential cuff 5 can be seen which is reduced in diameter by an oesophageal outlet 6 only on the distal end at the tip 4 whereas at the proximal end the cuff 5 passes through under the tube connecting connector 2. At the distal end the oesophageal outlet 6 passes over the cuff 5 in a type of channel.

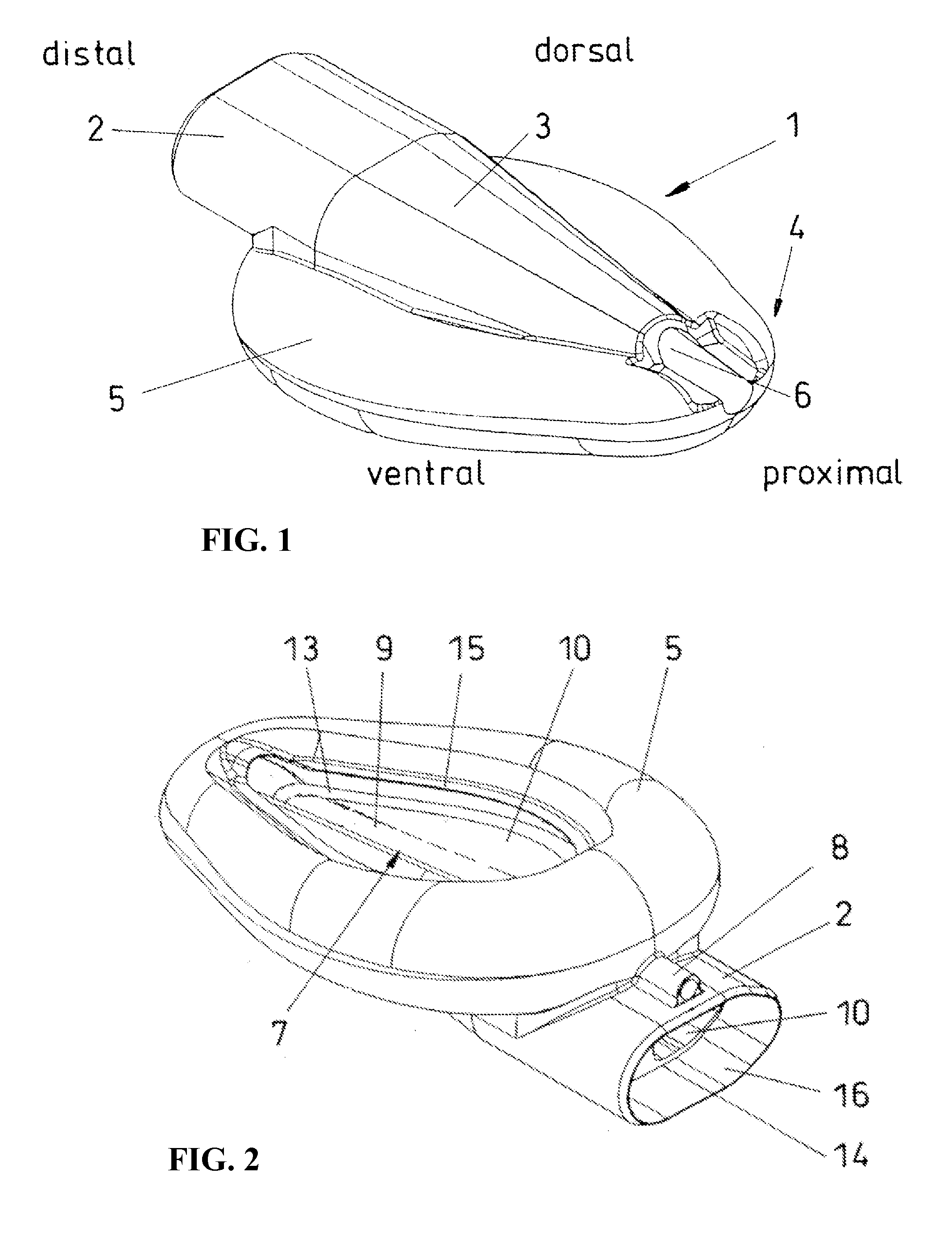

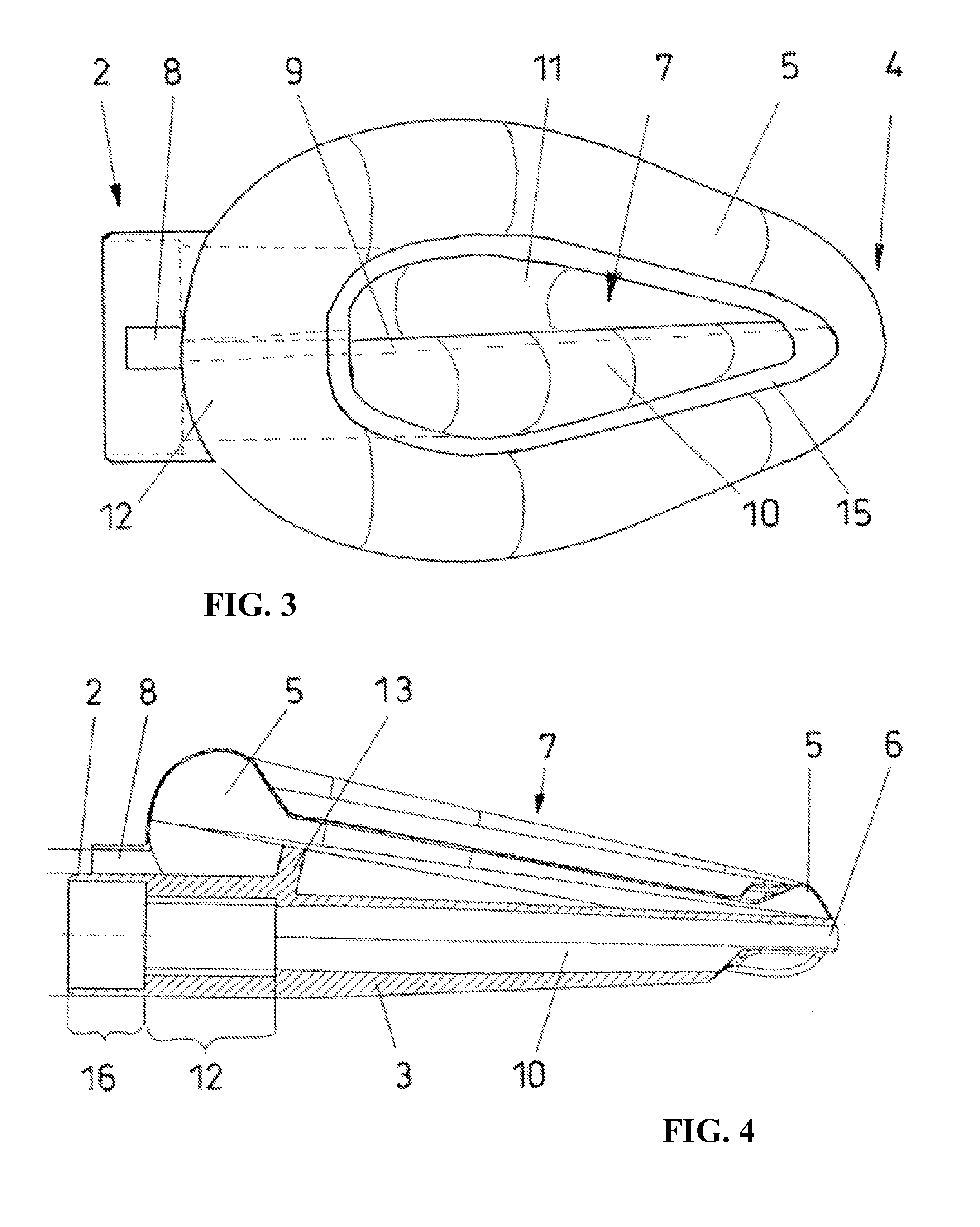

[0022]The cuff 5 is produced by open injection molding. In particular, in the cross-sections shown in FIGS. 6 and 7, but also in FIG. 2, a circumferent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| rigidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com