Grain storage structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

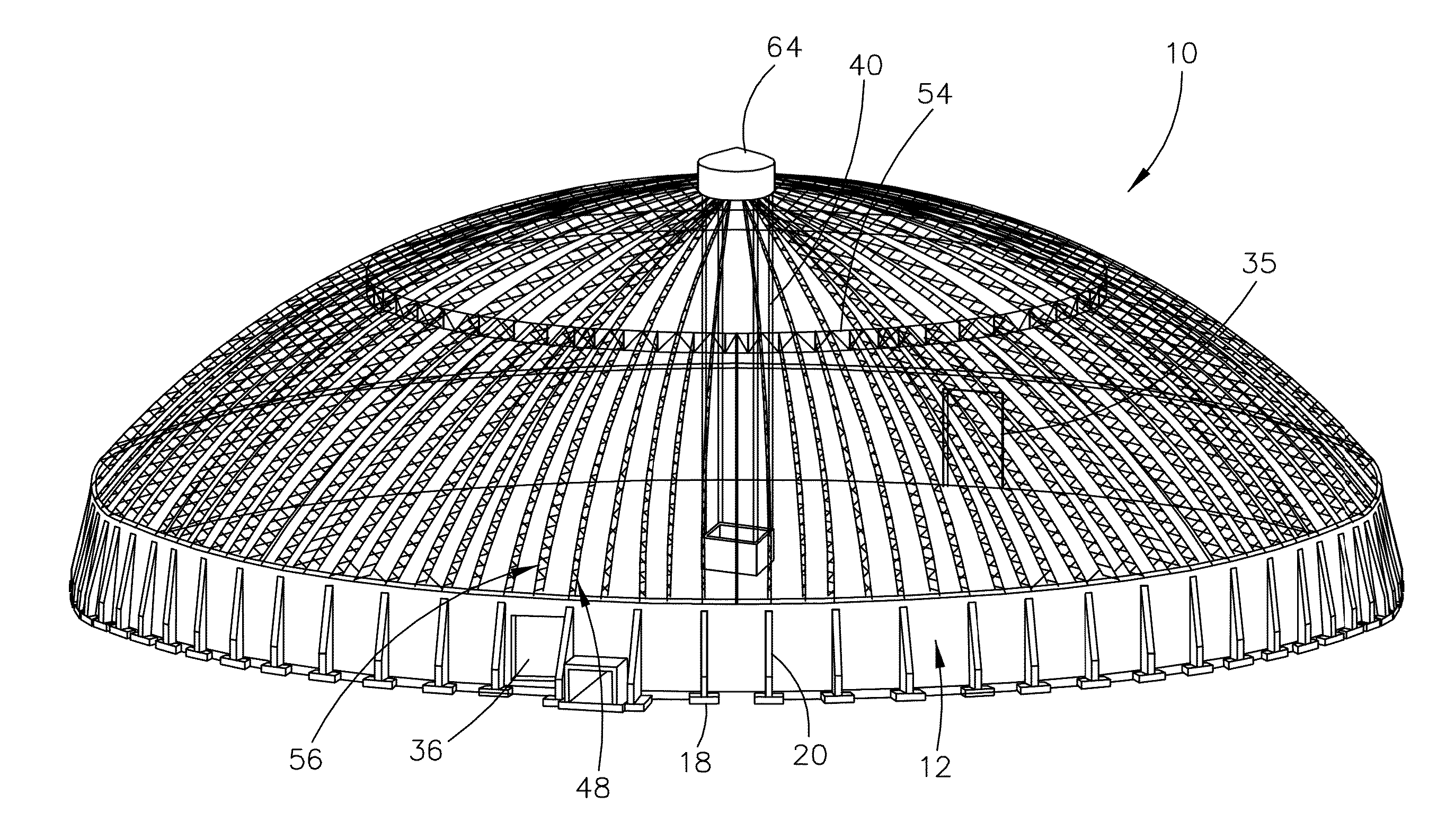

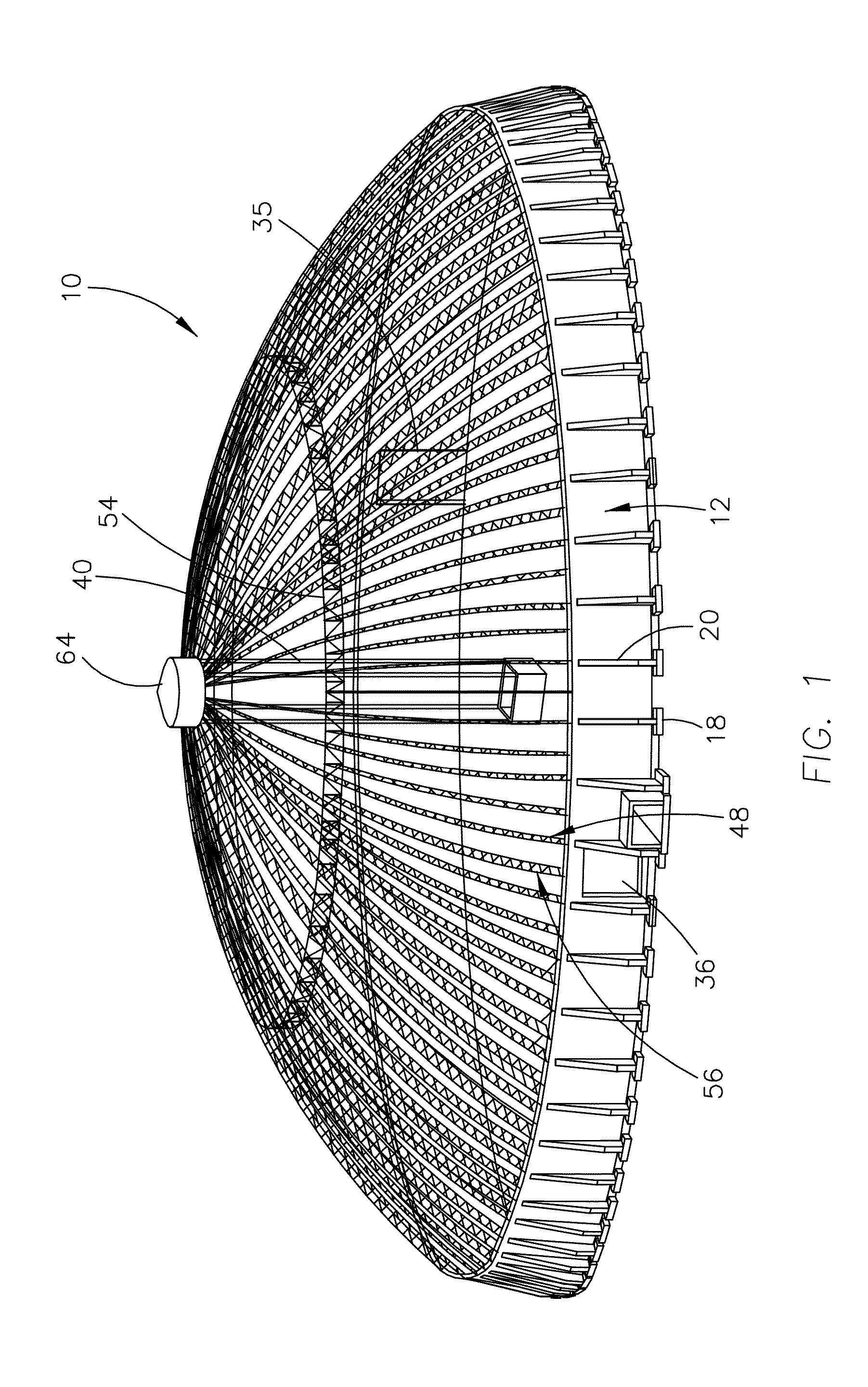

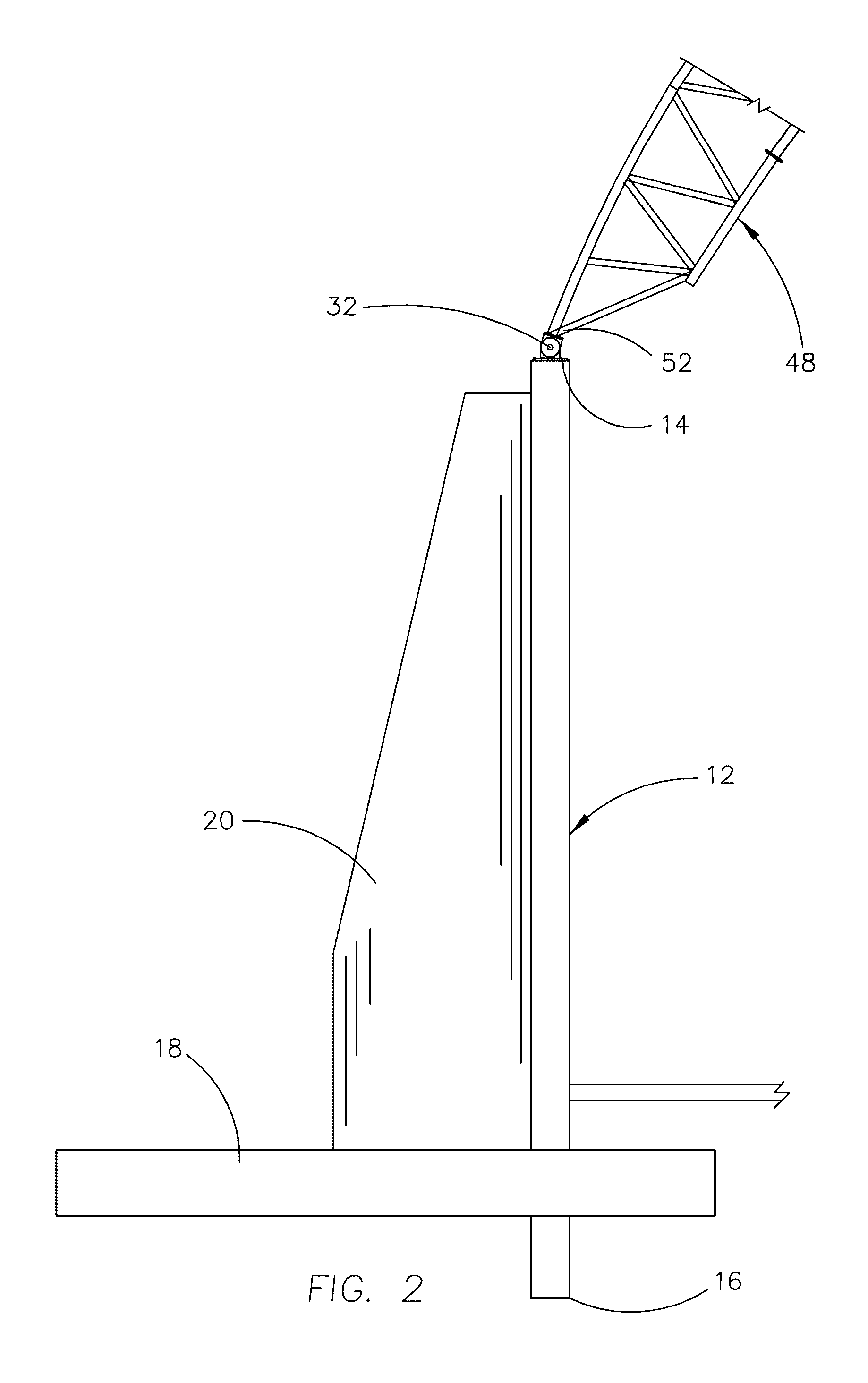

[0031]the grain storage structure of this invention is designated by the reference numeral 10. Structure 10 is of the hoop style and may have a diameter of up to 300 feet. Structure 10 is designed to hold up to 2.6 million bushels of grain. Structure 10 includes a circular concrete support wall 12 having an upper end 14 and a lower end 16. The lower end 16 of wall 12 will normally be embedded in the ground. Wall 12 includes radially spaced-apart ground engaging concrete pads 18 which are integrally formed with wall 12. A reinforcing web or member 20 is formed with each of the pads 18.

[0032]Wall 12 has a plurality of radially spaced-apart metal plates 22 which are positioned on the upper end of wall 12. At each plate 22 location, a plurality of anchor bolts 24, which are embedded in wall 12, extend upwardly through bolt openings formed in plate 22. Nuts 26 are threadably secured to the upper ends of anchor bolts 24 to hold plate 22 in position on the upper end of wall 12. A pair of v...

second embodiment

[0037]The numeral 66 refers to a grain storage structure. As seen, the structure 66, when viewed in a top view, has an oblong configuration. Structure 66 includes a first semi-circular support wall 68. Structure 66 also includes straight support walls 70 and 72 which extend from the ends of support wall 68. Structure 66 further includes a second semi-circular support wall 74 which extends between the ends of walls 70 and 72, as seen in FIG. 7. The support walls 68, 70, 72 and 74 form a continuous support wall which is identical to support wall 12 of structure 10 except for the oblong configuration.

[0038]Structure 66 includes a vertically disposed support tower 76 which is centrally positioned between the ends of the semi-circular support wall 68, as seen in FIG. 7. Structure 66 also includes a vertically disposed support tower 78 which is centrally positioned between the ends of the semi-circular support wall 74, as seen in FIG. 7. An elongated support beam or truss 80 extends betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com