Radiator heating device using vacuum spiral heat pipe

a heating device and vacuum technology, applied in the direction of electrical heating fuel, domestic stoves or ranges, lighting and heating apparatus, etc., can solve the problems of excessive fuel cost, contaminating the air environment, excessive generation of harmful electromagnetic waves, etc., to maximize heating efficiency, effectively carry out seat heating, and reduce energy used in the volume range of the heating devi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Hereinafter, the present invention will be described in detail with respect to the configuration thereof with reference to accompanying drawings, which preferably illustrate the present invention.

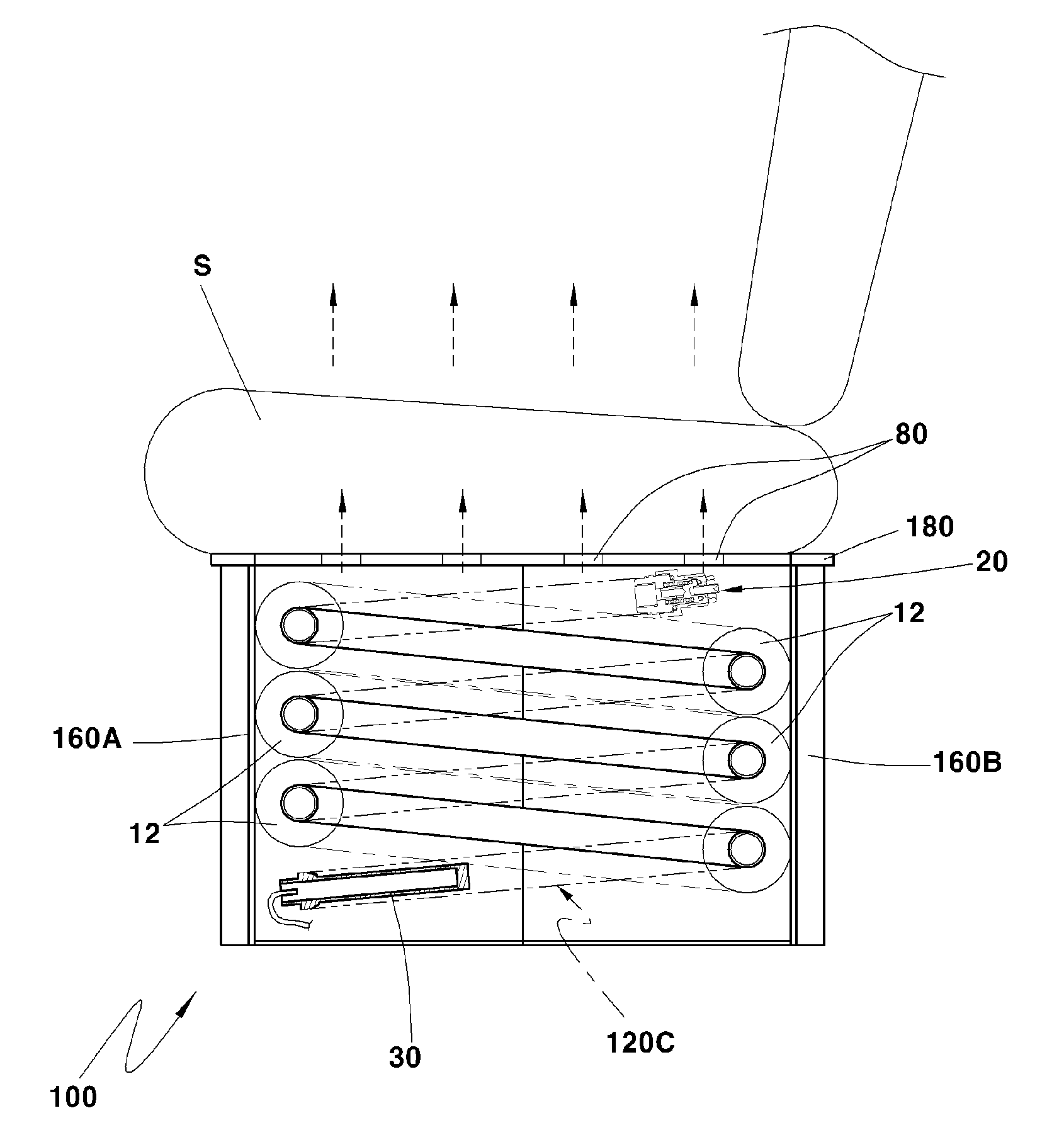

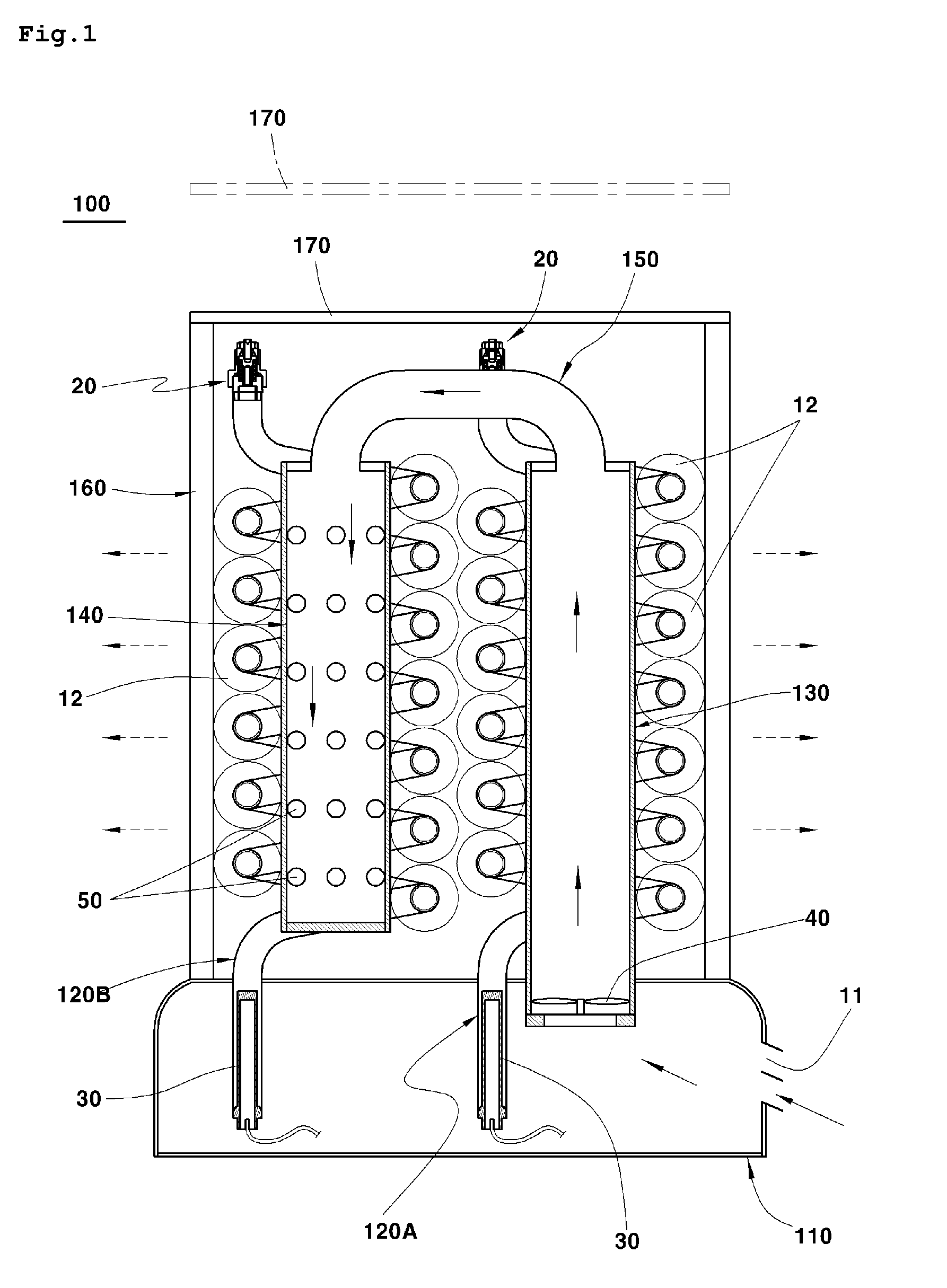

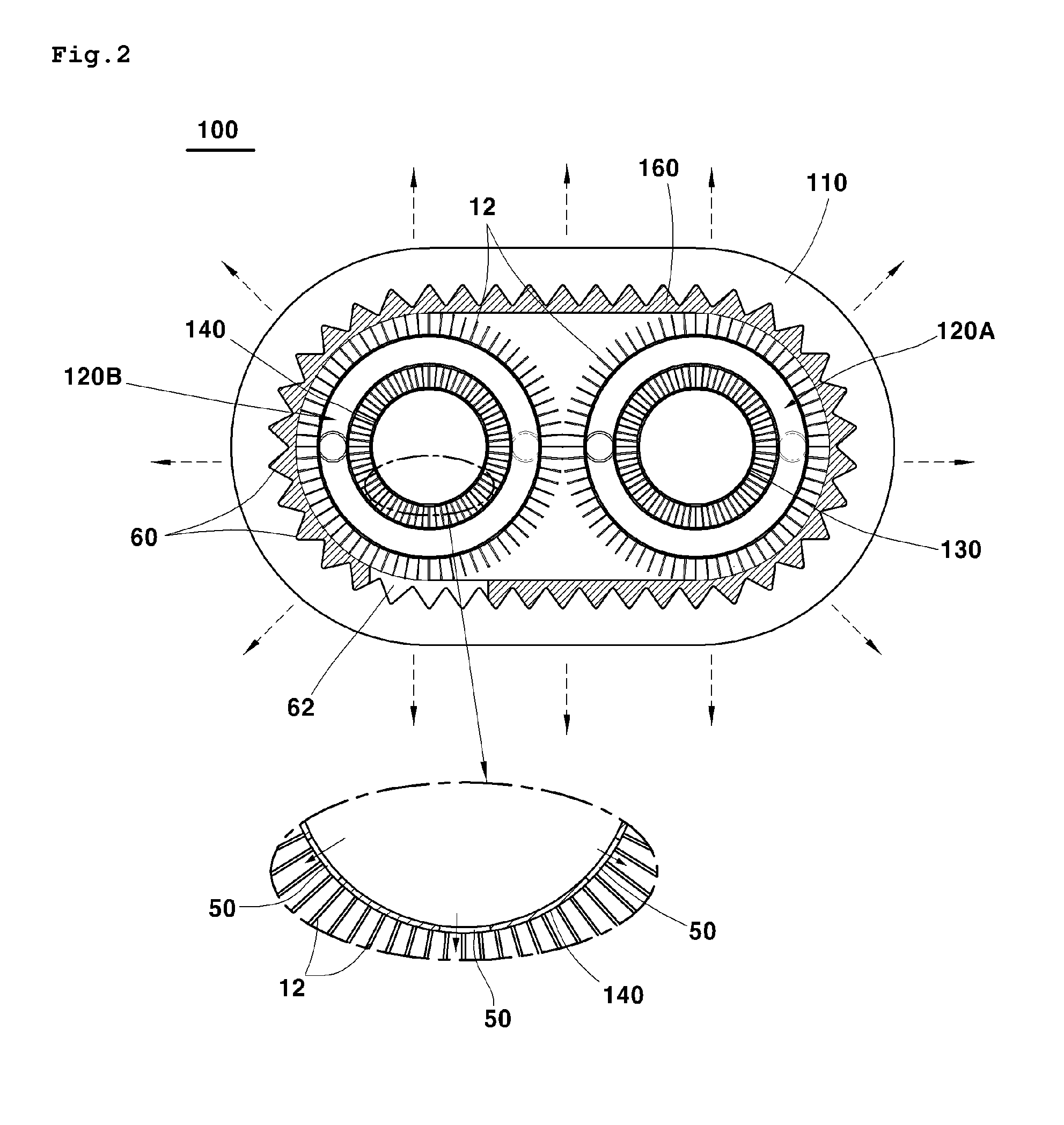

[0026]According to the present invention, in a radiator heating device, the heating device (100), as shown in FIG. 1 to FIG. 3, includes: a lower support (110) provided with an air hole (11) for inducing external introduction air; a first heat pipe (120A) and a second heat pipe (120B) as hollow pipes, each of which incorporates a heating medium, and has upper and lower parts, which are formed linearly, a spiral heat exchange part (10), which is integrally formed in the shape of a coil spring between the upper and lower parts, a plurality of circular radiating plates (12) coupled to the outside circumference of the spiral heat exchange part in close contact therewith, a vacuum pressure control valve (20) provided to the upper end portion thereof, and a heater heating part (30) incorpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com