Method for ethane liquefaction

a technology of liquefaction and apparatus, applied in the direction of refrigeration and liquidation, solidification, lighting and heating apparatus, etc., can solve the problems of high irreversible losses, high thermal stress, and inability to use brazed aluminum heat exchangers, so as to reduce the number of liquid recycle loops or eliminate them, the effect of reducing the efficiency of the compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032]While the invention will be described in connection with several embodiments, it will be understood that it is not intended to limit the invention to those embodiments. On the contrary, it is intended to cover all the alternatives, modifications and equivalence as may be included within the spirit and scope of the invention defined by the appended claims.

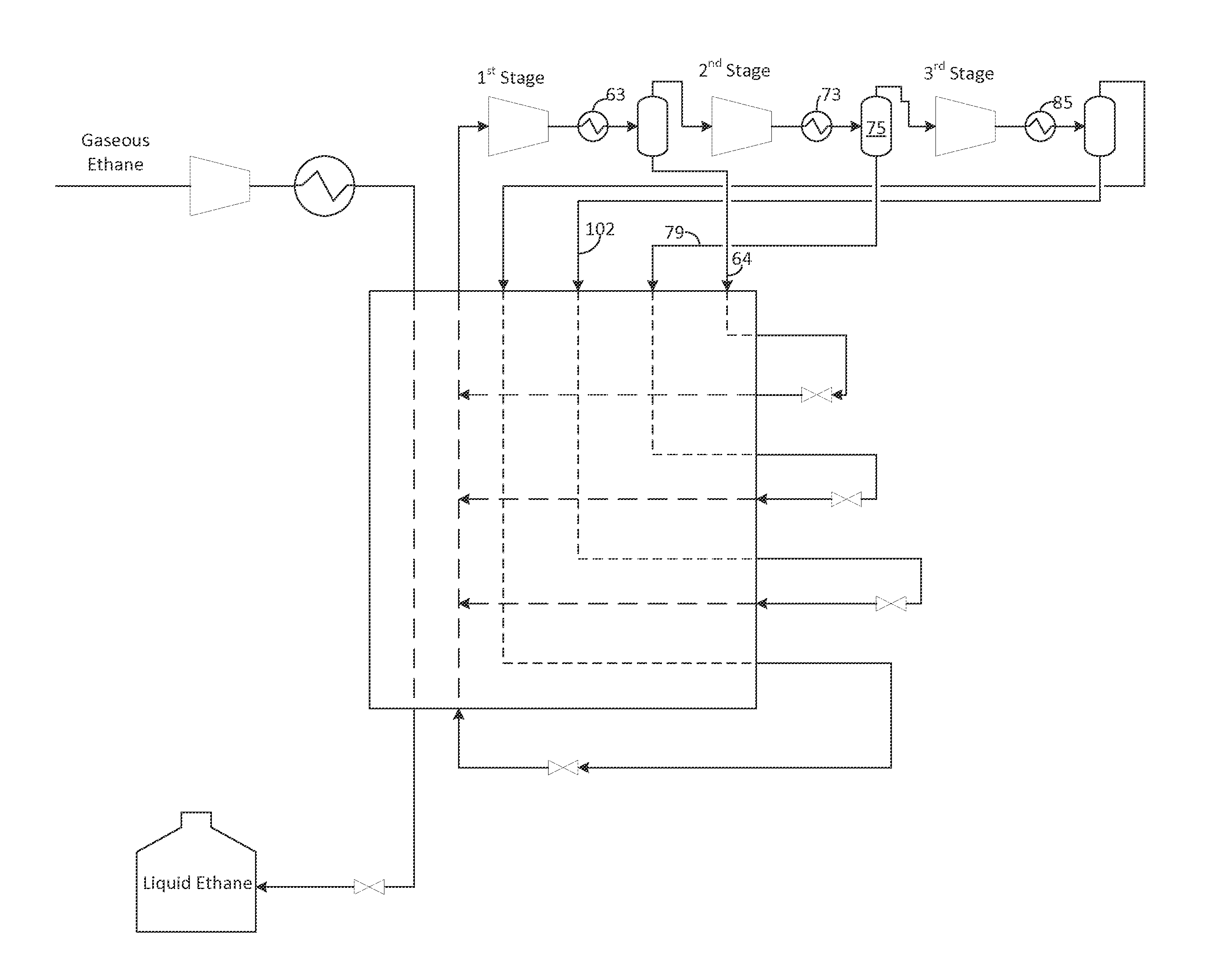

[0033]To overcome the problems associated with the cascading refrigeration cycle of FIG. 1, the natural progression of development for one skilled in the art would be to propose using a mixed refrigerant process similar to those used in LNG processes. However, because ethane liquefies at a warmer temperature than methane (i.e., LNG), large quantities of heavier components (e.g., butane and / or pentane) would be the natural choice of the refrigerant. For example, a typical mixed refrigerant composition for LNG production is 30% methane, 38% ethane, 11% propane, 6% butane, 15% pentane

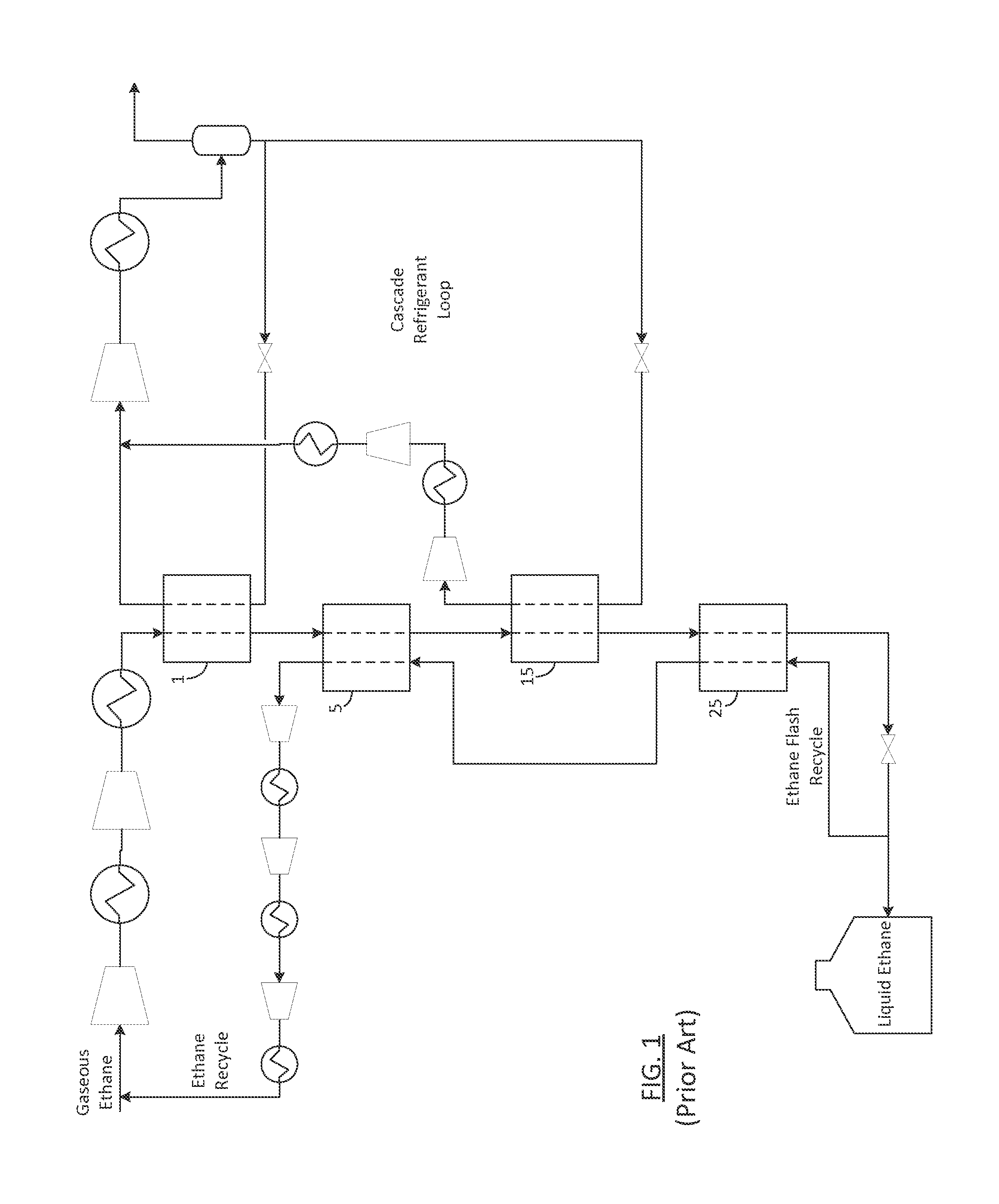

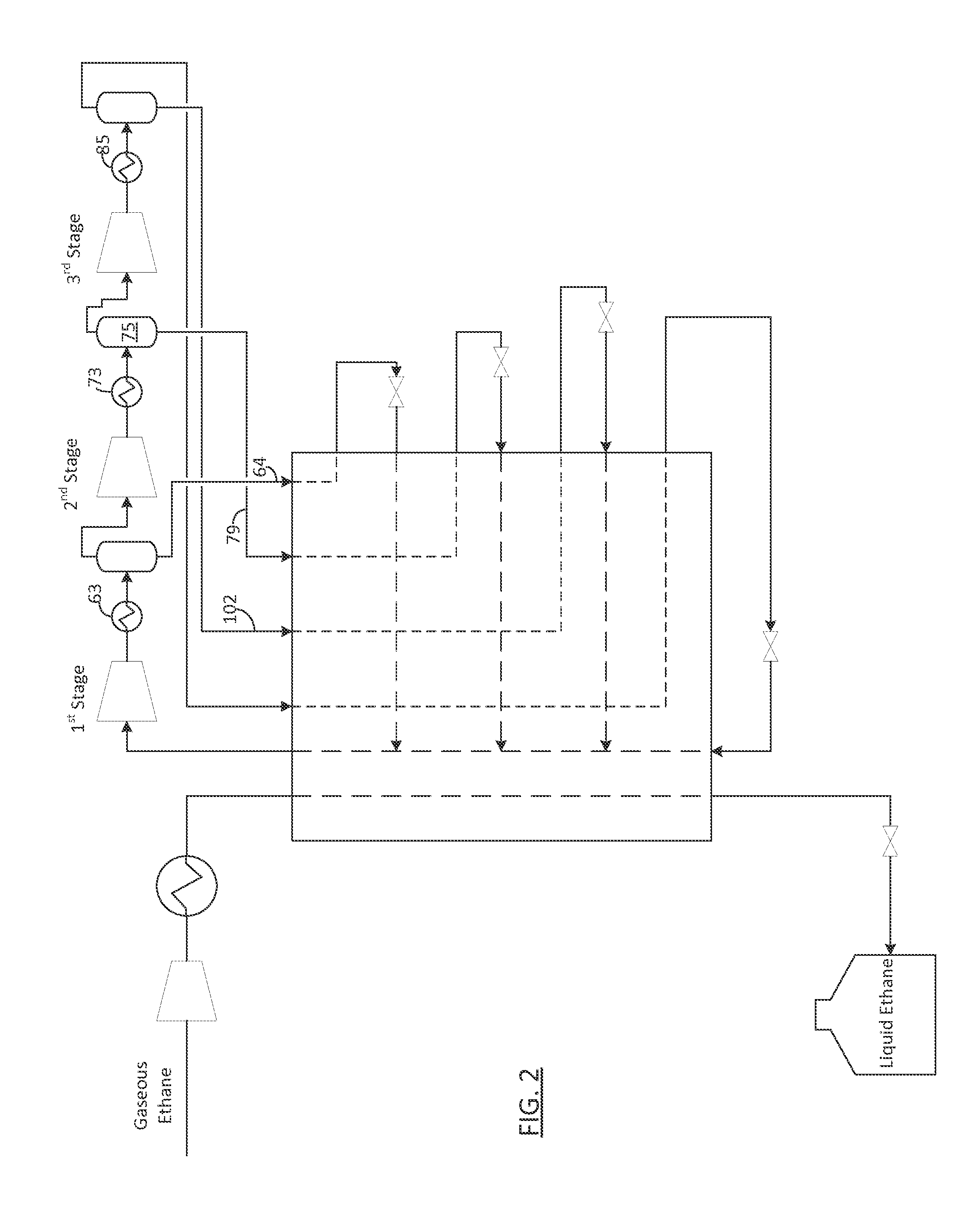

[0034]FIG. 2 provides an example of a thermody...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com