Petroleum instrument salvaging system and salvaging head

a technology for salvaging systems and petroleum instruments, applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., can solve the problems of severe environmental conditions inside the drilling well, damage to petroleum instruments, so as to reduce the economic loss caused by stopping drilling, improve efficiency, and reduce labor intensity and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The embodiments of the invention provide a salvaging head for a petroleum instrument salvaging system, thereby solving the current problems of large labor intensity, low efficiency, high cost high cost and large economic loss due to stopping drilling, which are caused by replacing or examining and repairing a petroleum instrument via pulling drill rods out of the drilling well.

[0036]In order to make one skilled in the art better understand the technical solutions in the embodiments of the invention and to make the above objects, characteristics and advantages of the embodiments of the invention more apparent, the technical solutions in the embodiments of the invention will be further illustrated in detail in conjunction with the drawings.

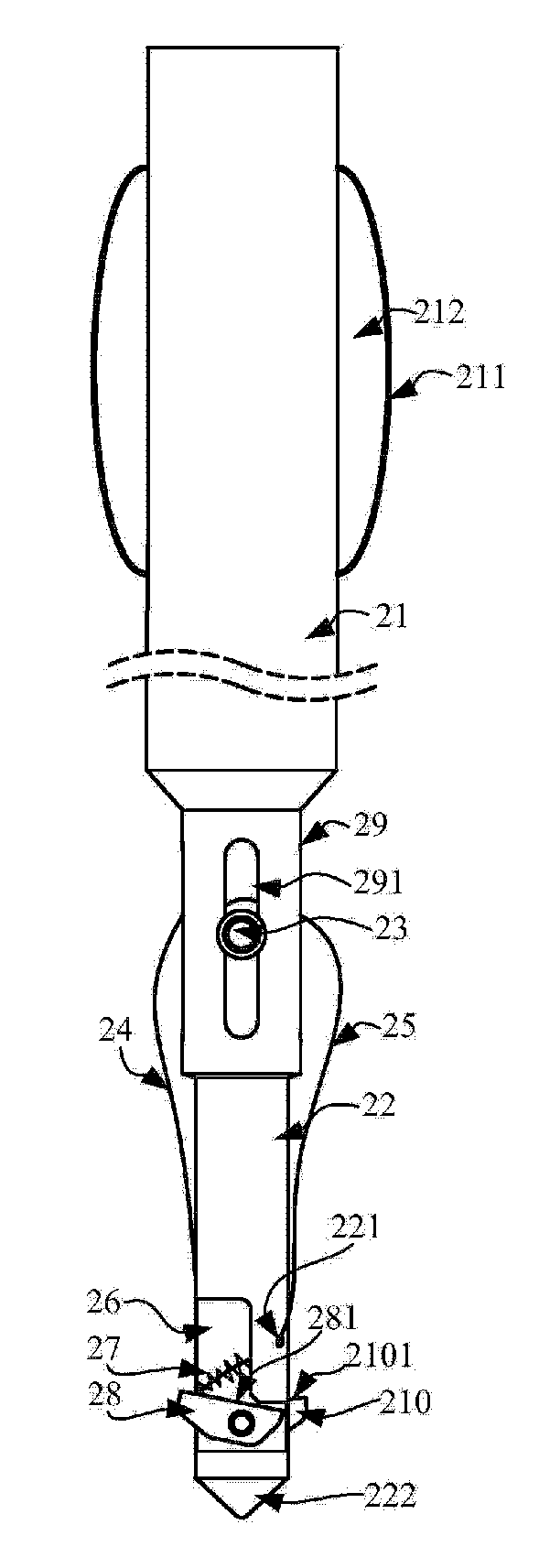

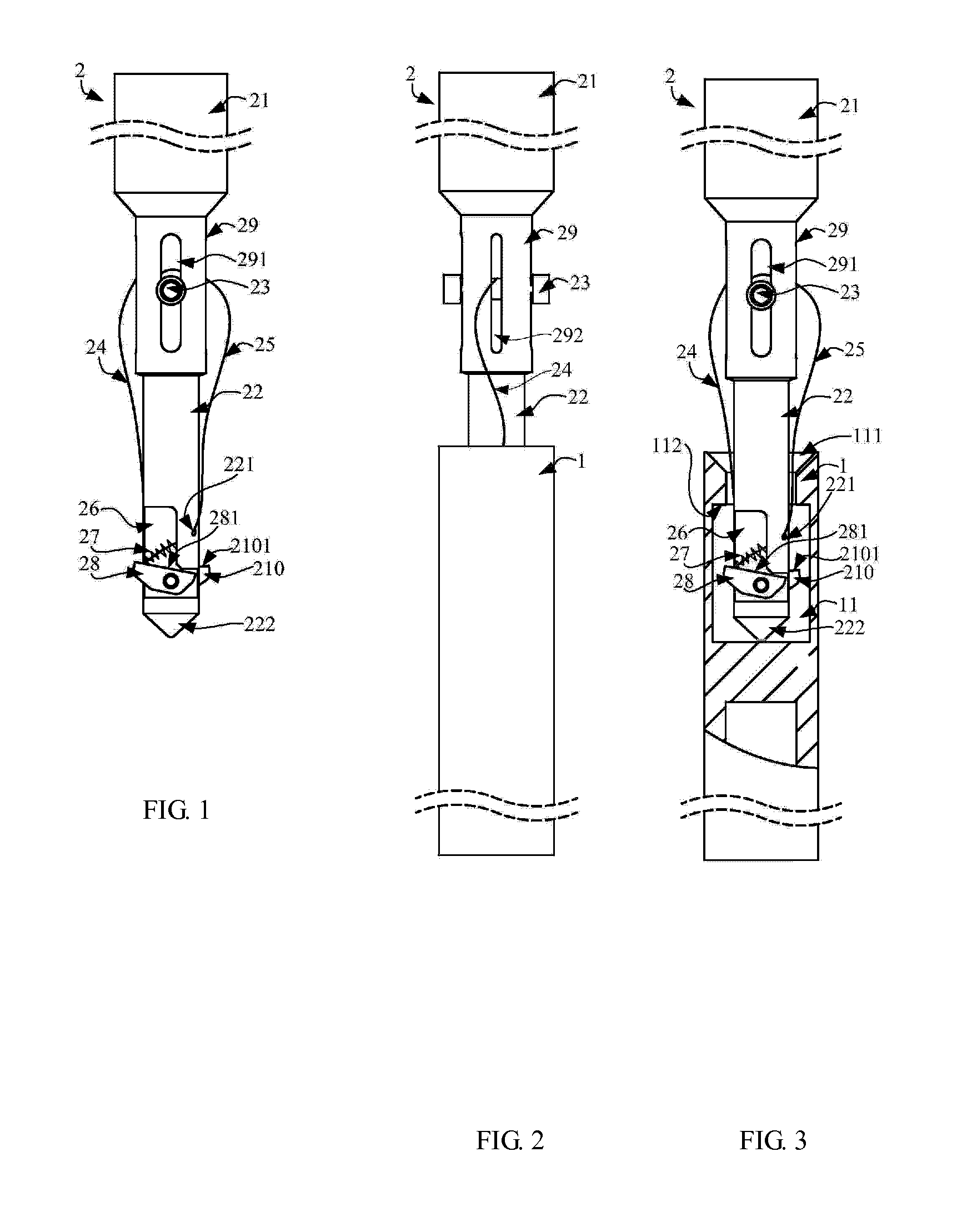

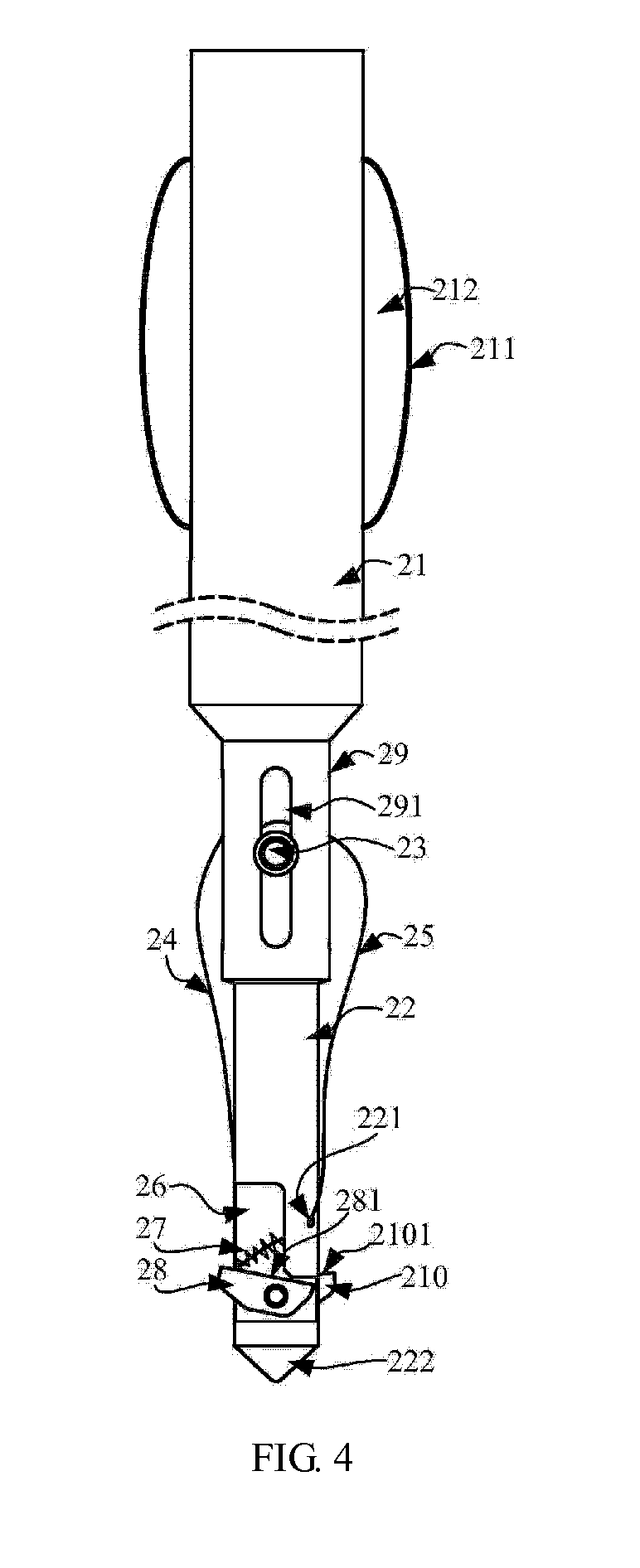

[0037]Referring to FIGS.1-3, one embodiment of the invention provides a salvaging head 2 for a petroleum instrument salvaging system, and the salvaging head 2 provided is used for the salvaging of a petroleum instrument 1. The petroleum instru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com