Projectile with amorphous polymer tip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

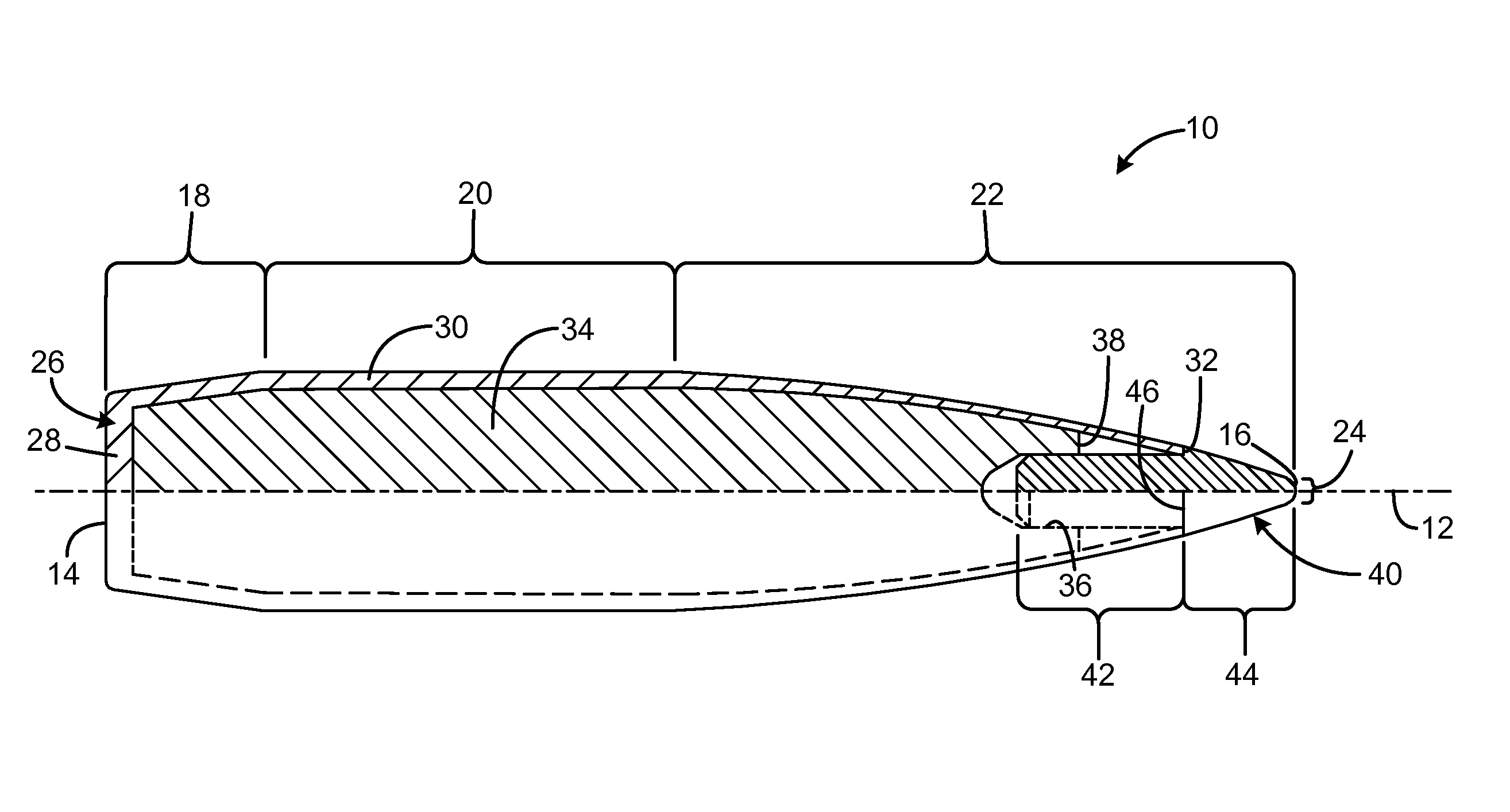

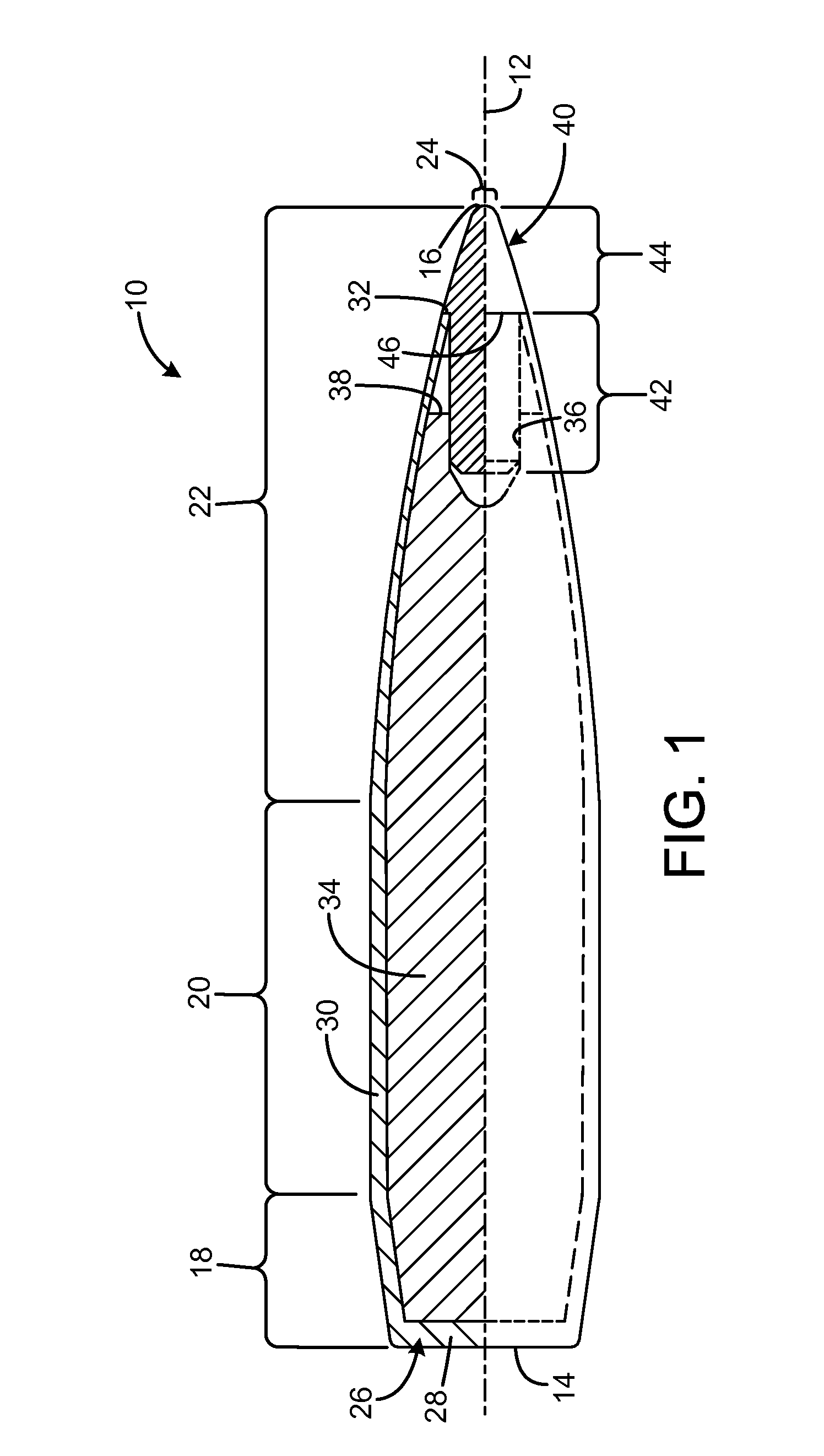

[0023]An embodiment of the projectile with amorphous plastic tip of the present invention is shown and generally designated by the reference numeral 10.

[0024]FIG. 1 illustrates the improved projectile 10 of the present invention. More particularly, the projectile is a generally cylindrical body, symmetrical in rotation about an axis 12, with a rear end 40 and a forward tip 16. The projectile has an exterior surface shaped as follows: a rear portion 18 has a tapered frustoconical “boat tail” surface; a cylindrical intermediate portion 20 continues forward from the rear portion with a straight cylindrical side wall. Continuing, a forward ogive surface portion 22 has a gentle curve toward a meplat portion 24 at the tip. The meplat is a small diameter spherical portion. The ogive has a larger radius (as taken in a plane including the bullet's axis, as illustrated) than the intermediate section's diameter (taken in section across the axis), and also a much larger radius than that of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com