Operating system utilizing an articulated bolt train to manage recoil force

a technology of operating system and recoil force, which is applied in the direction of weapons, butts, weapon components, etc., can solve the problems of ineffective volume and total weight of different means used to achieve recoil absorption, and no previous patent used active firing mechanisms,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

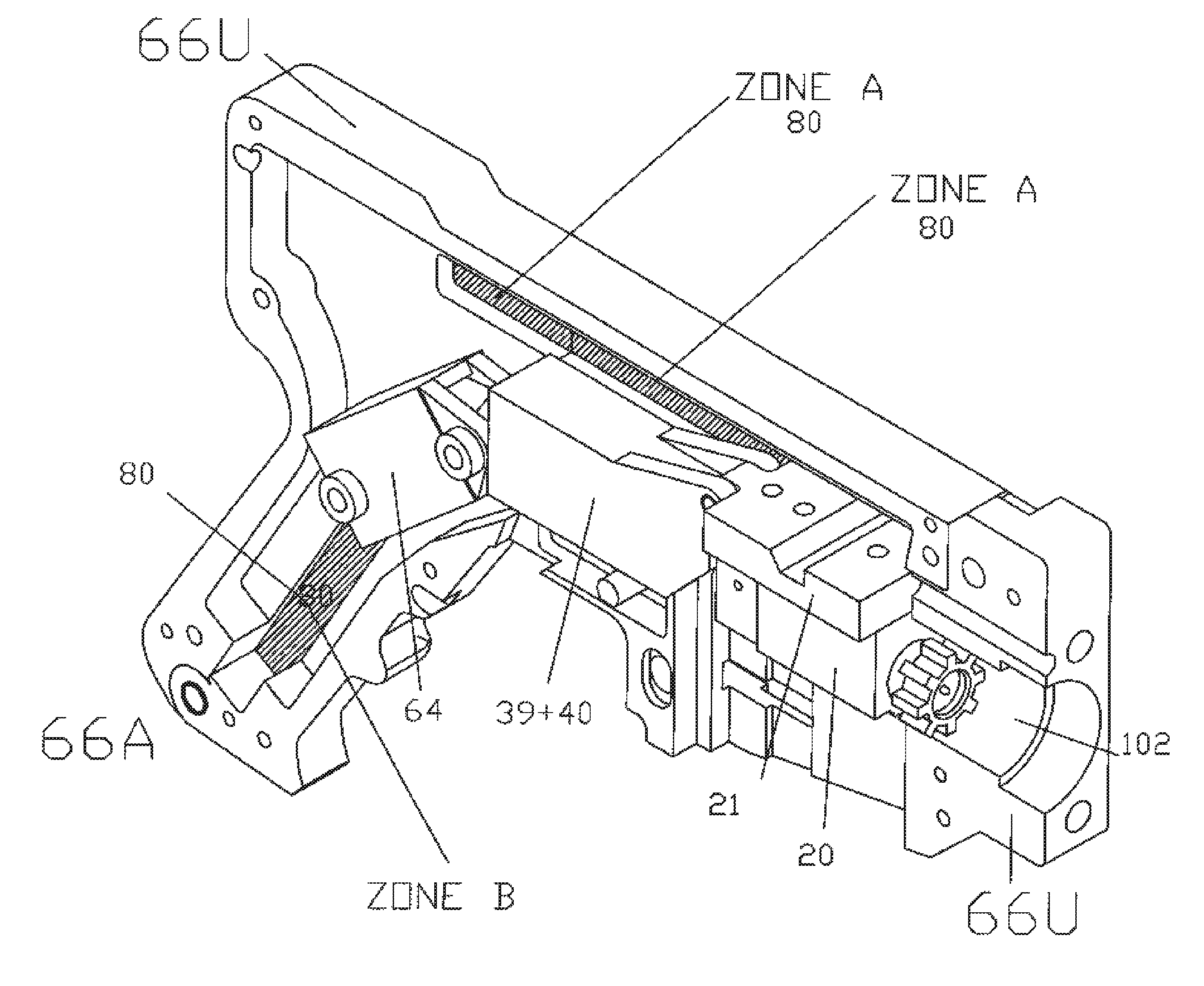

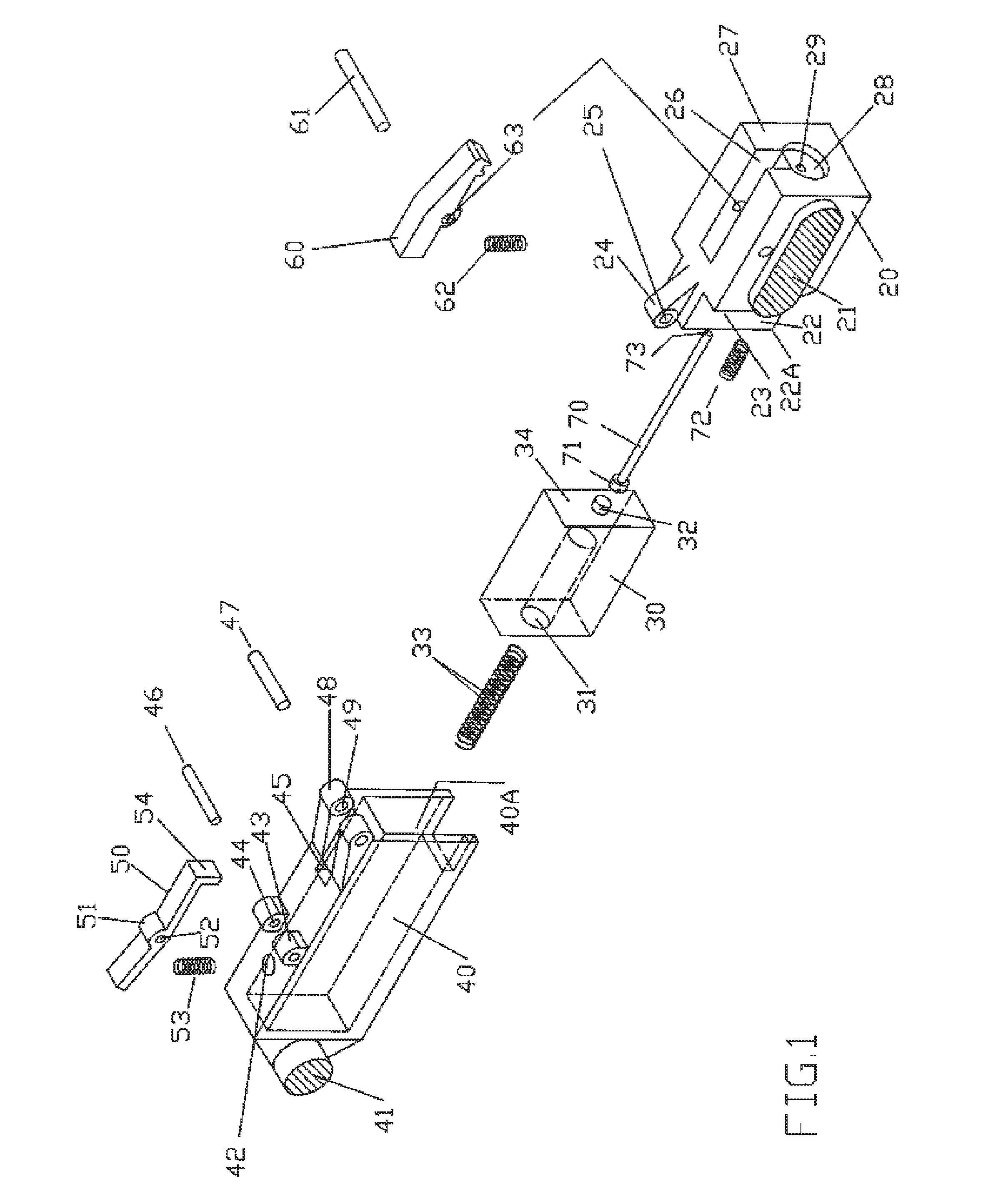

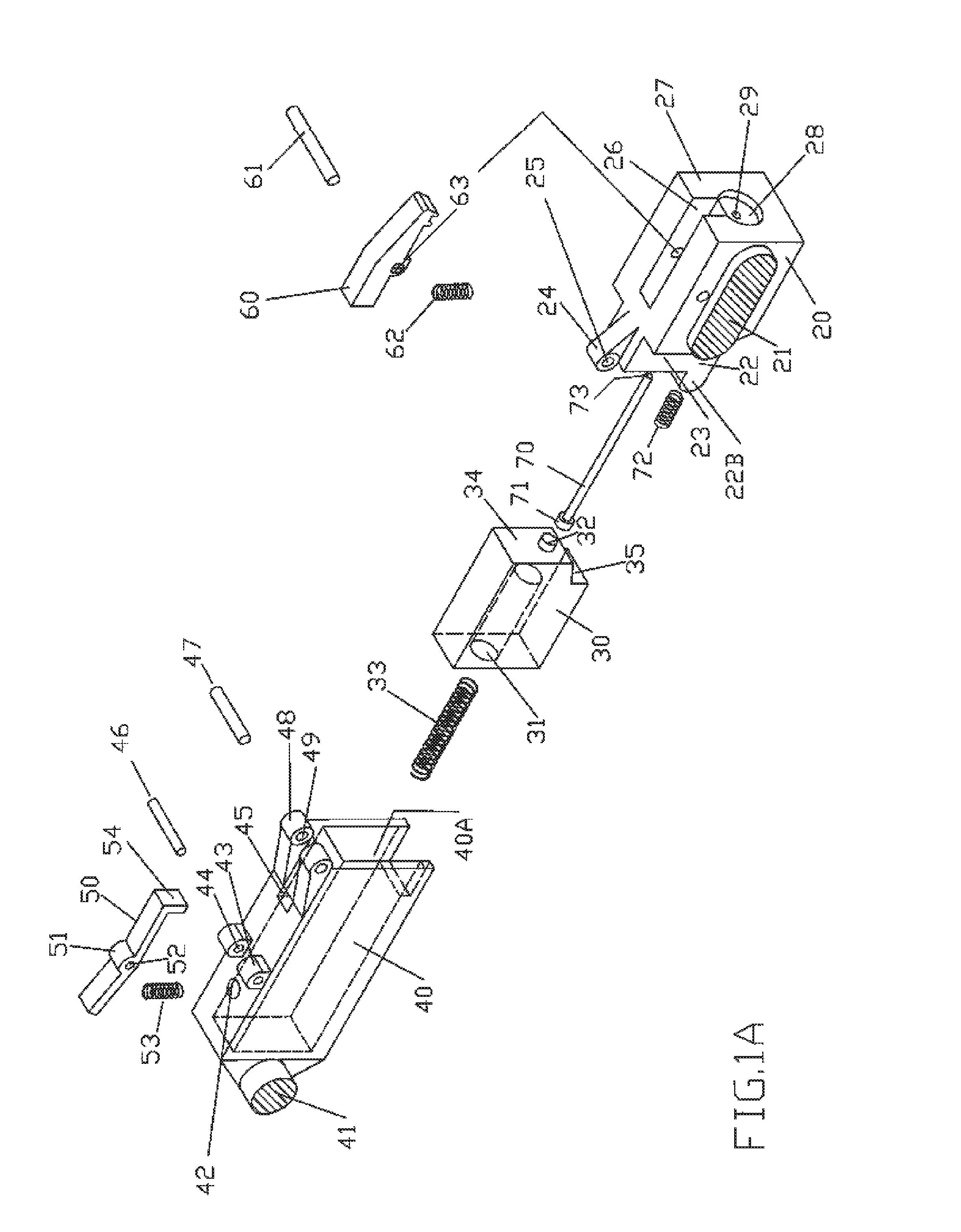

Embodiment Construction

[0228]a. This invention presents a linearly displacing hammer. Similar results in terms of recoil absorption can be obtained by placing a compact array of firing mechanisms with conventional rotary parts behind the front bolt as a part of another type of traveling mechanisms carriage, however it would require more volume, which defeats the purpose of accommodating the traveling mechanisms in a tight space such as the inside of the handgrip.[0229]b. Additional recoil absorption can be achieved by placing conventional shock absorbers, hydraulic or pneumatic, rubber pads at the end of the cavity that receives the mechanisms carrier housing 40. Elastomeric shock absorber can be placed to additionally abate the recoil by allowing the recoiling mechanisms carrier housing 40 stop against them.[0230]c. Neither the mechanisms carrier cavity 40A, the hammer 30, nor the mechanism carriers housing 30 are necessarily rectangular. They are of the convenient shape to accommodate a convenient shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

| Dynamic | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com