Heat pipe

a technology of heat pipe and heat flux, which is applied in the direction of indirect heat exchangers, lighting and heating apparatus, etc., can solve the problems of not being able to take into account the cost and effect of heat pipe, the configuration of the heat pipe is still too complex, and the prior art heat pipe cannot meet the demand for discharging a lot of heat and high heat flux, so as to achieve easy manufacturing, improve the quality and yield of heat pipe manufacturing, and improve the effect of heat pipe quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]A heat pipe according to a preferred embodiment of the present invention will be apparent from the following detailed description, which proceeds with reference to the accompanying drawings, wherein the same references relate to the same elements.

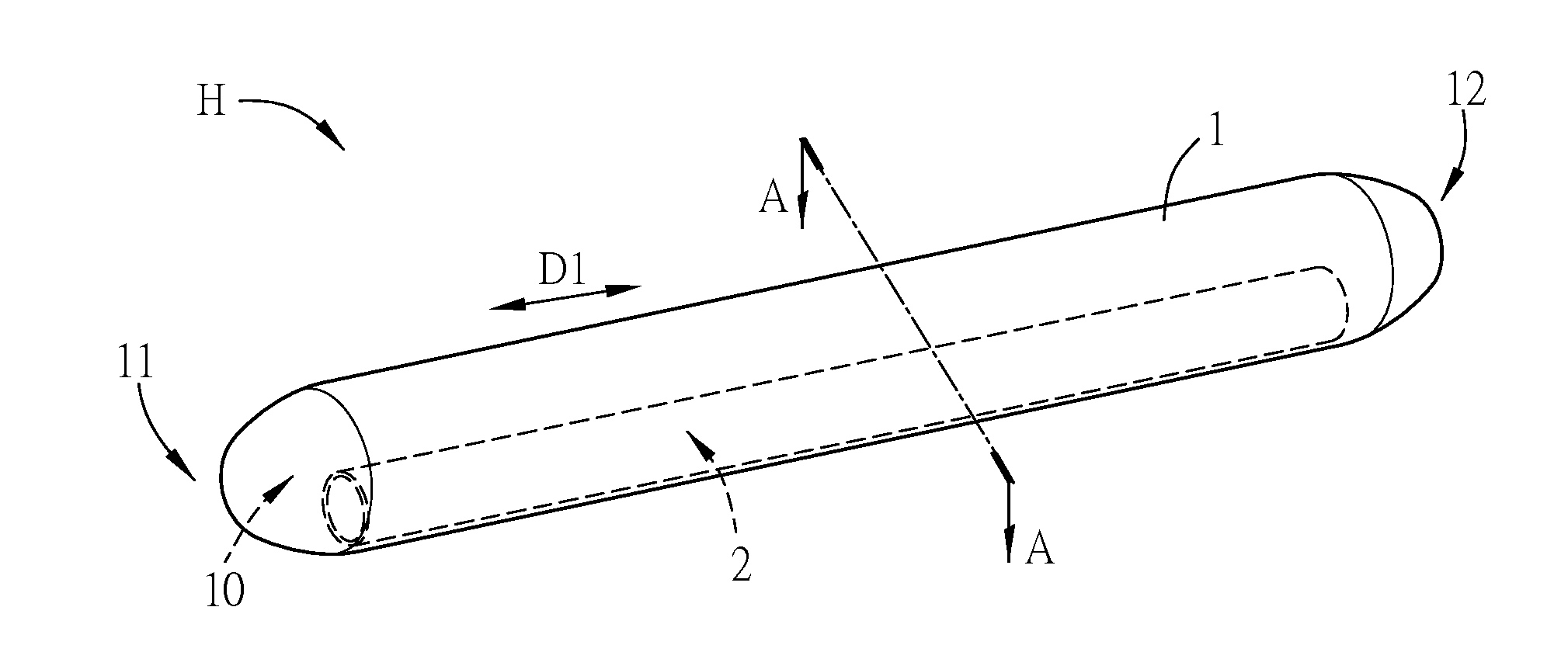

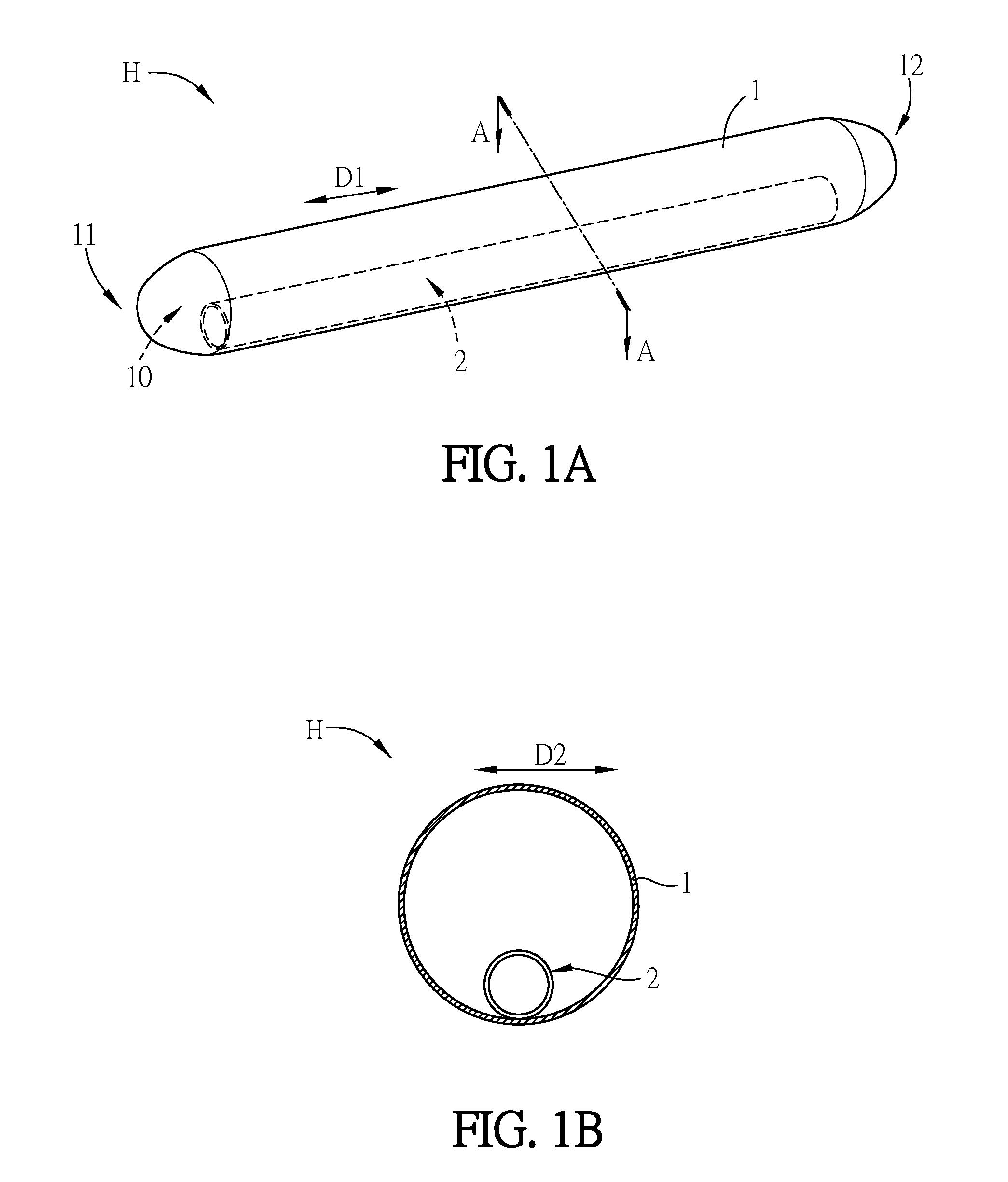

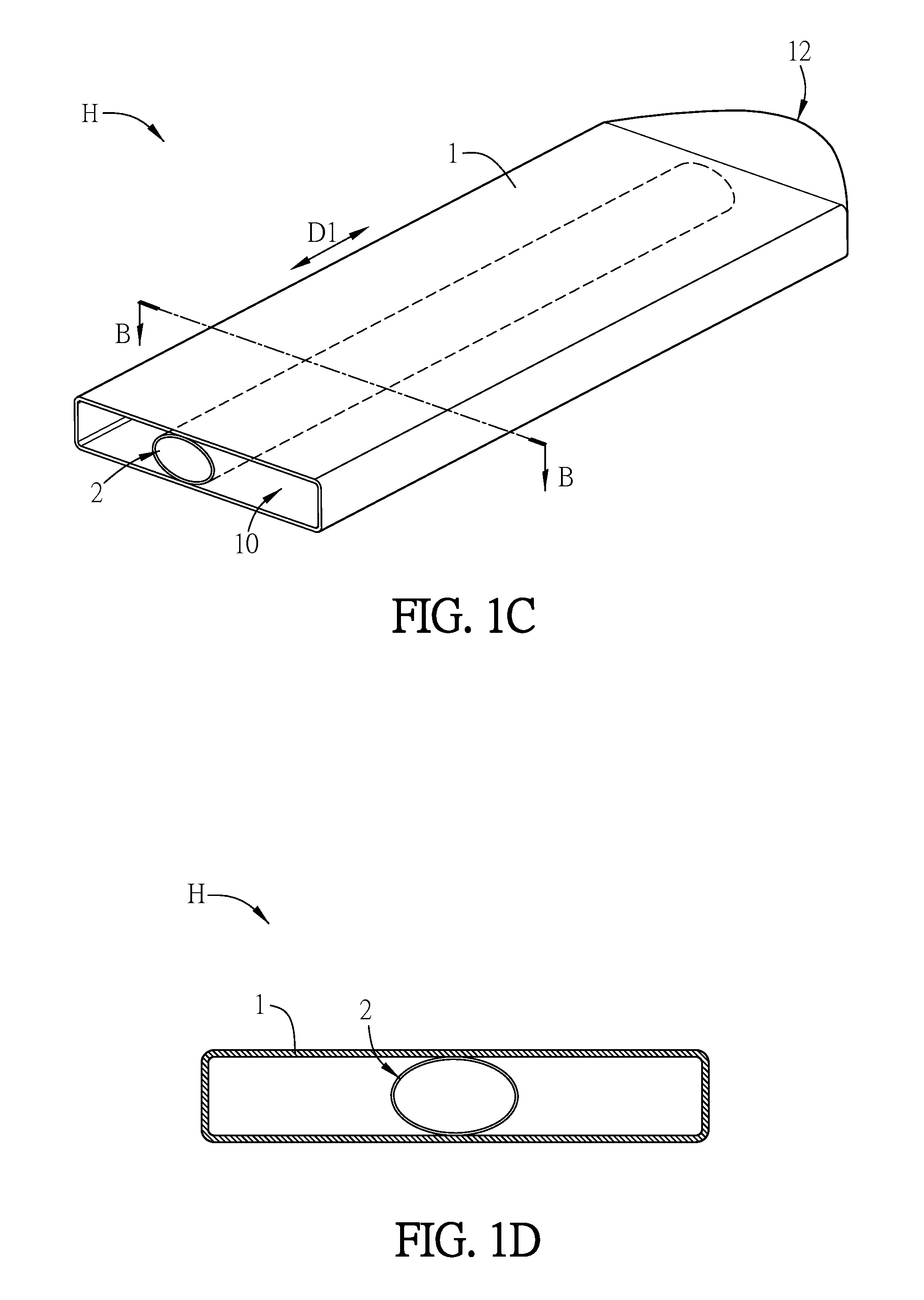

[0034]FIG. 1A is a schematic view of partial heat pipe according to a preferred embodiment of the present invention. FIG. 1B is a cross-sectional view taken along line A-A of the heat pipe in FIG. 1A. In the embodiment, a heat pipe H includes a first pipe 1 and at least one second pipe 2. In the embodiment, one second pipe is 2 is utilized. The first pipe 1 is formed with an enclosed space 10. The second pipe 2 is disposed in the enclosed space 10. There is no wick structure disposed between the first pipe 1 and the second pipe 2.

[0035]In the embodiment, the first pipe 1 is an elliptic cylindrical pipe with a thin wall. A section taken along a radial direction of the first pipe is a uniform section. The first pipe 1 can be made of Cu,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com