Polymer film heat exchanger with integral fluid distribution manifolds and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018]A heat exchanger operates to transfer heat from one fluid to another. The fluid can be liquid, vapor, or gas or a combination of the matter states. Hygroscopic fluids can be extremely useful in certain heat exchanger applications to limit water use. Hygroscopic fluids can be extremely corrosive and polymers can provide excellent resistance to corrosive fluids.

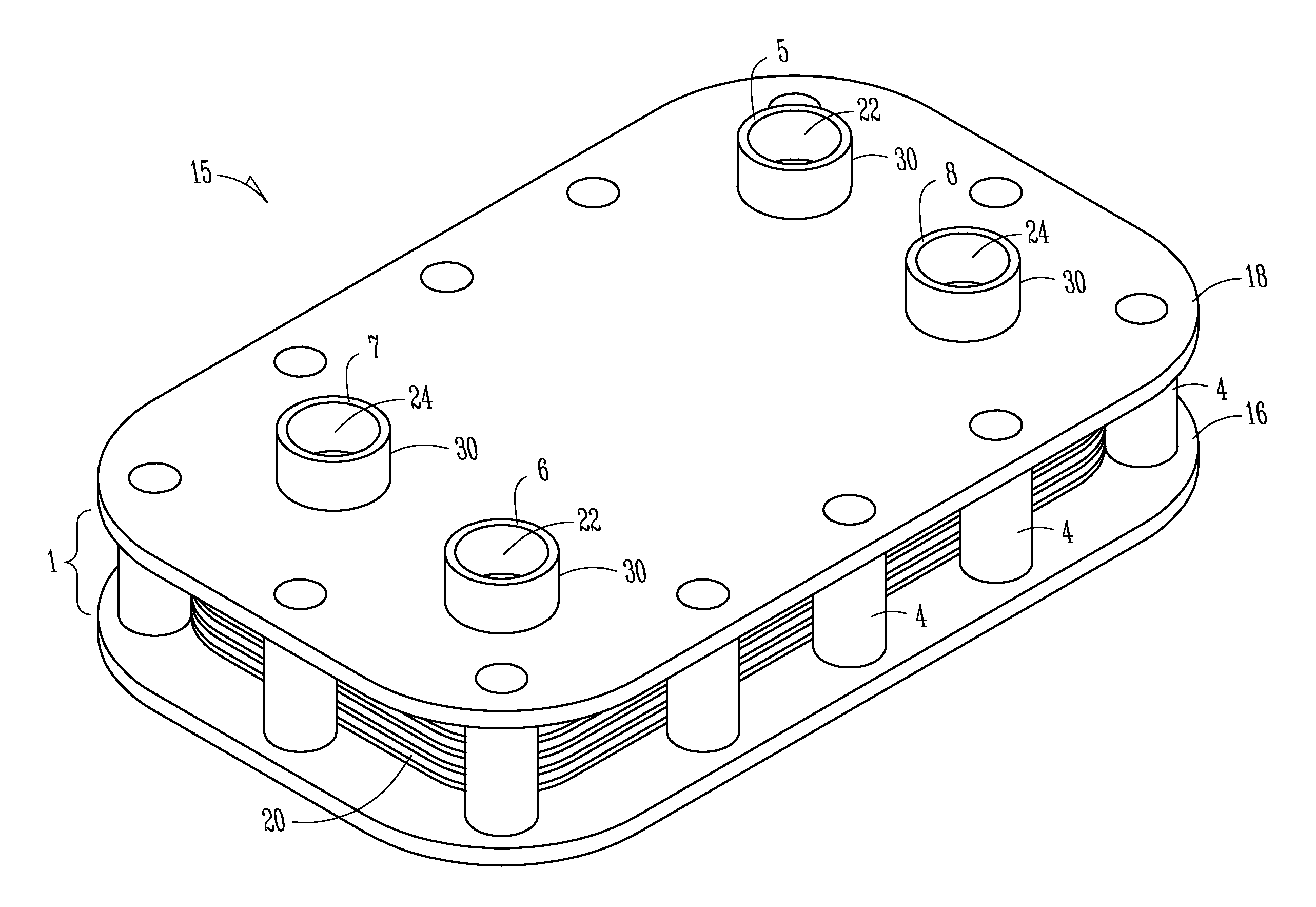

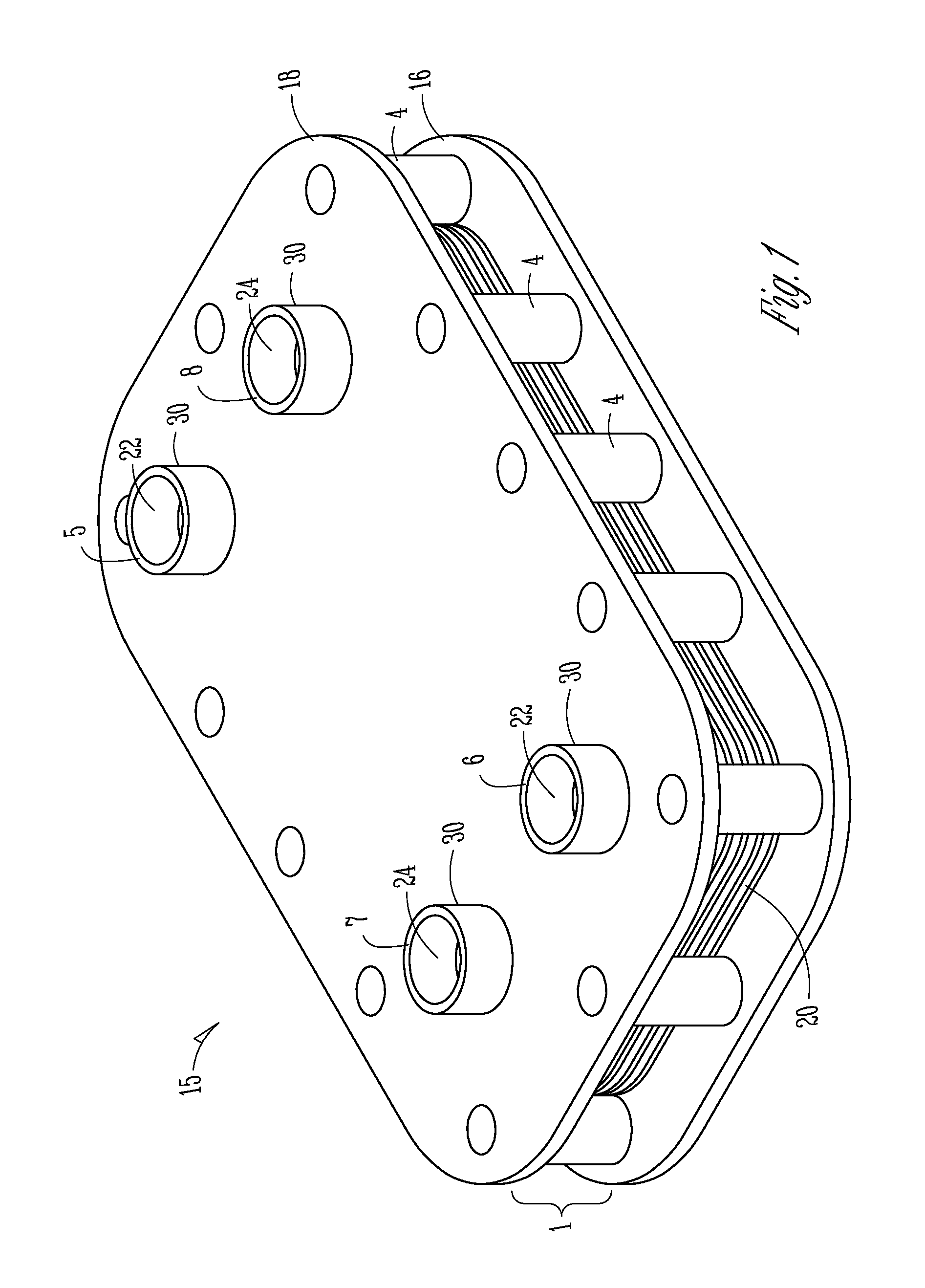

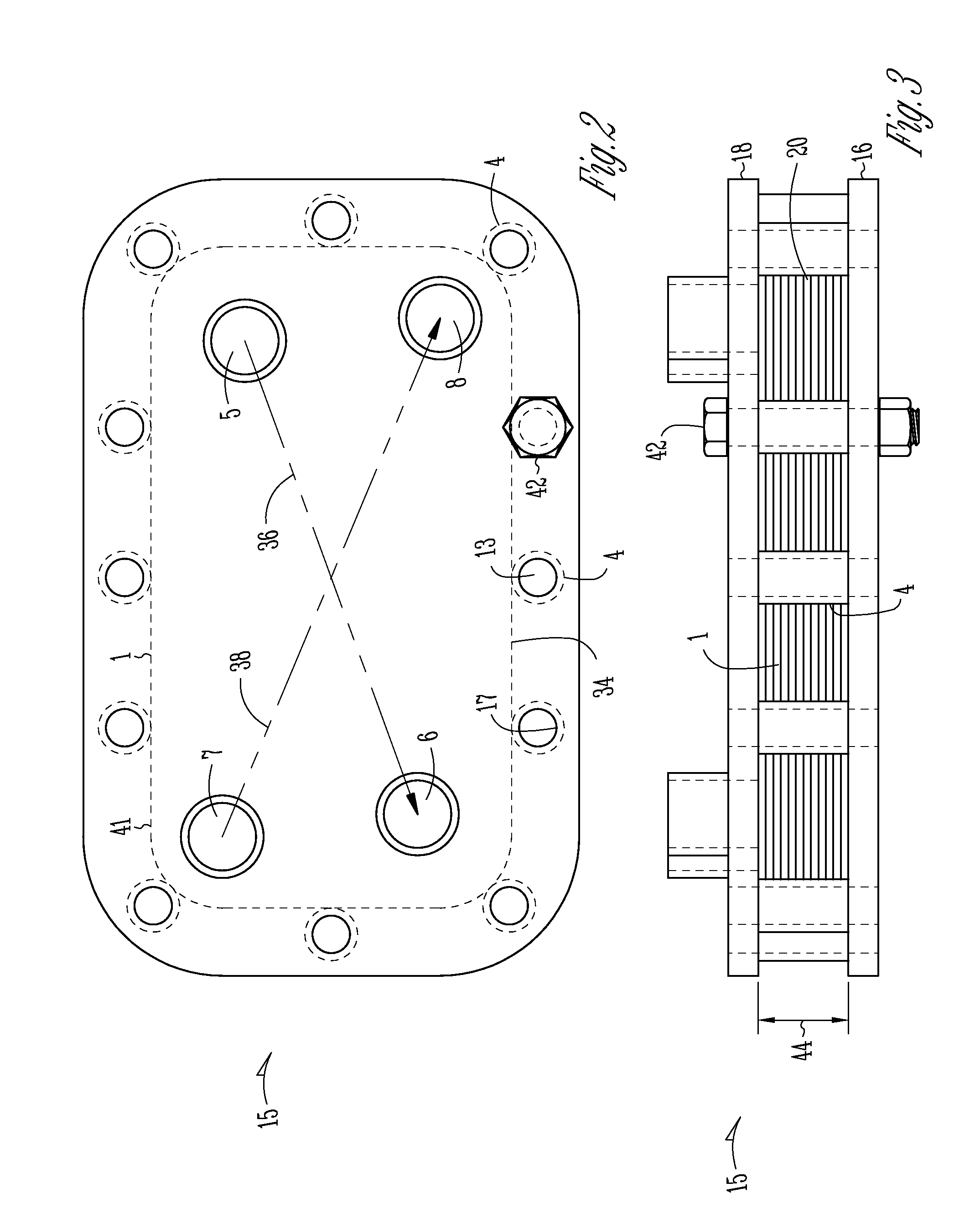

[0019]There is a need for a polymer heat exchanger that is low cost in construction and less complicated than previous heat exchangers. Described herein is a heat exchanger that includes a stack of film layers (film stack). The film stack can include alternating fluid passages that are separate from each other. Each fluid passage can include an input port and an output port and the input ports and output ports can be arranged so that the heat exchanger operates on a counter flow basis; fluid A flows in one direction and fluid B flows in the opposite direction.

[0020]The entire fluid circuit for both heat-transfer fluids, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimension | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Bond | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com