Acoustic microreactor and methods of use thereof

a microreactor and acoustic technology, applied in the field of acoustic microreactors, can solve the problems of complicated antibody binding quantitation and limited utility of protein a

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

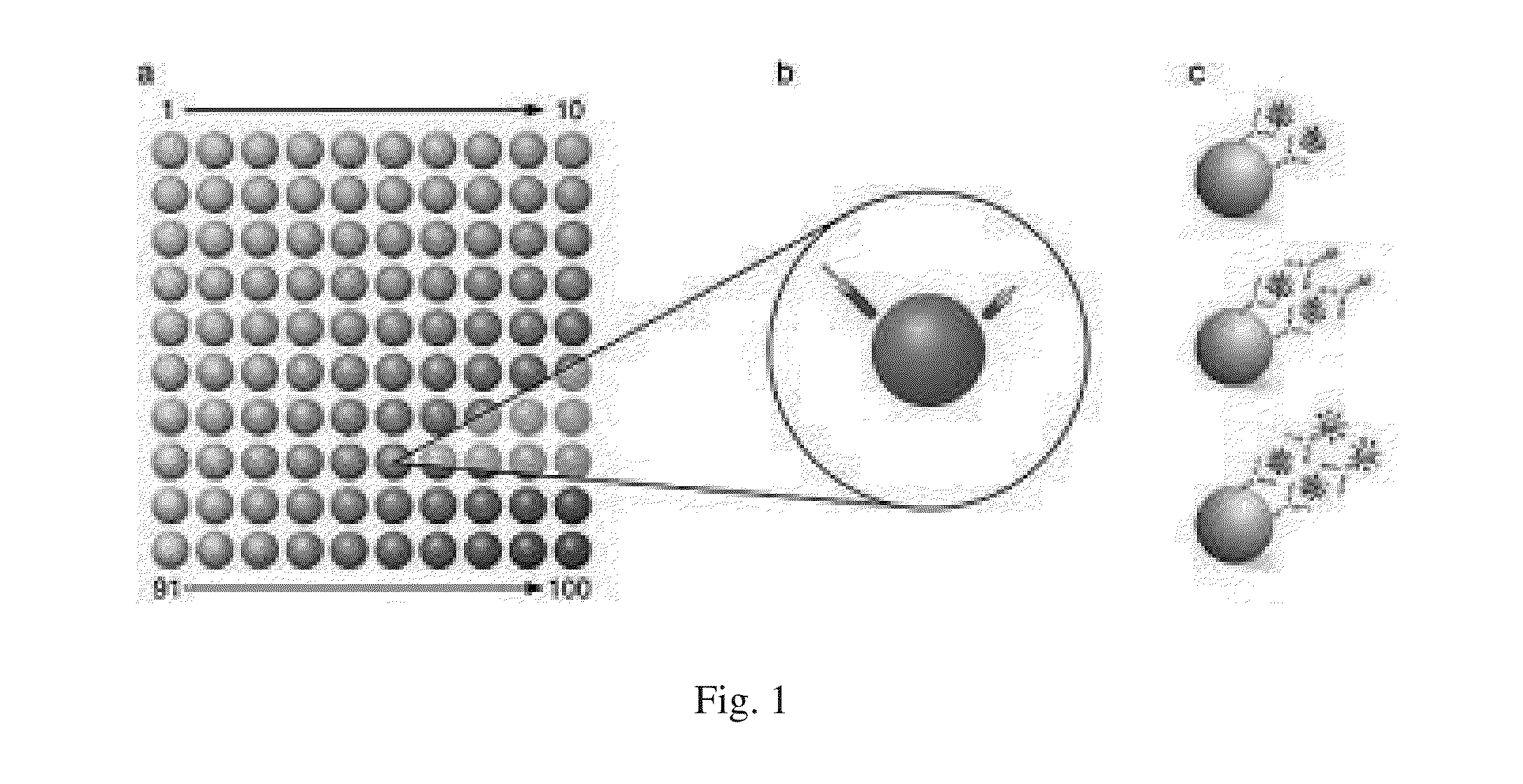

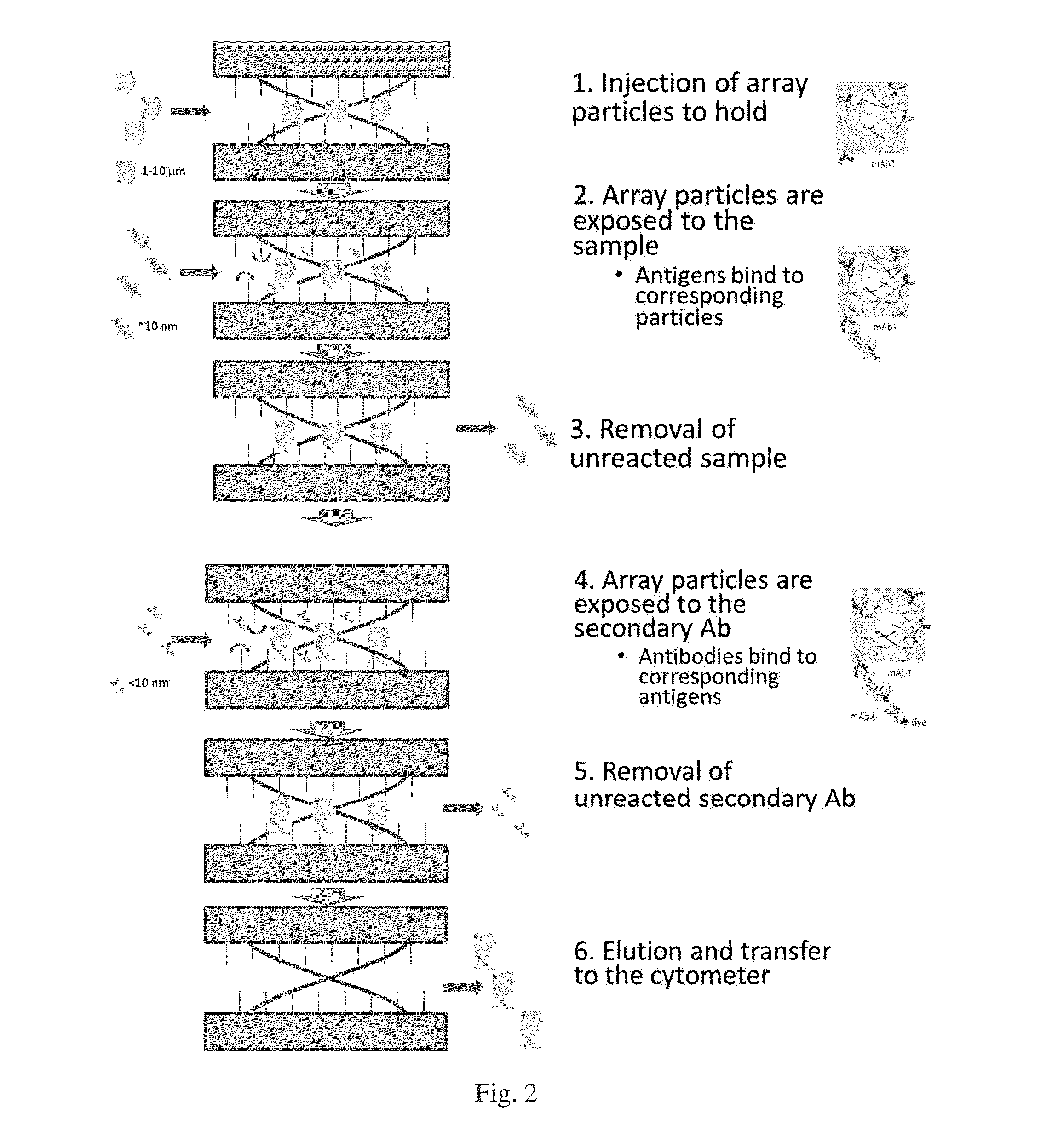

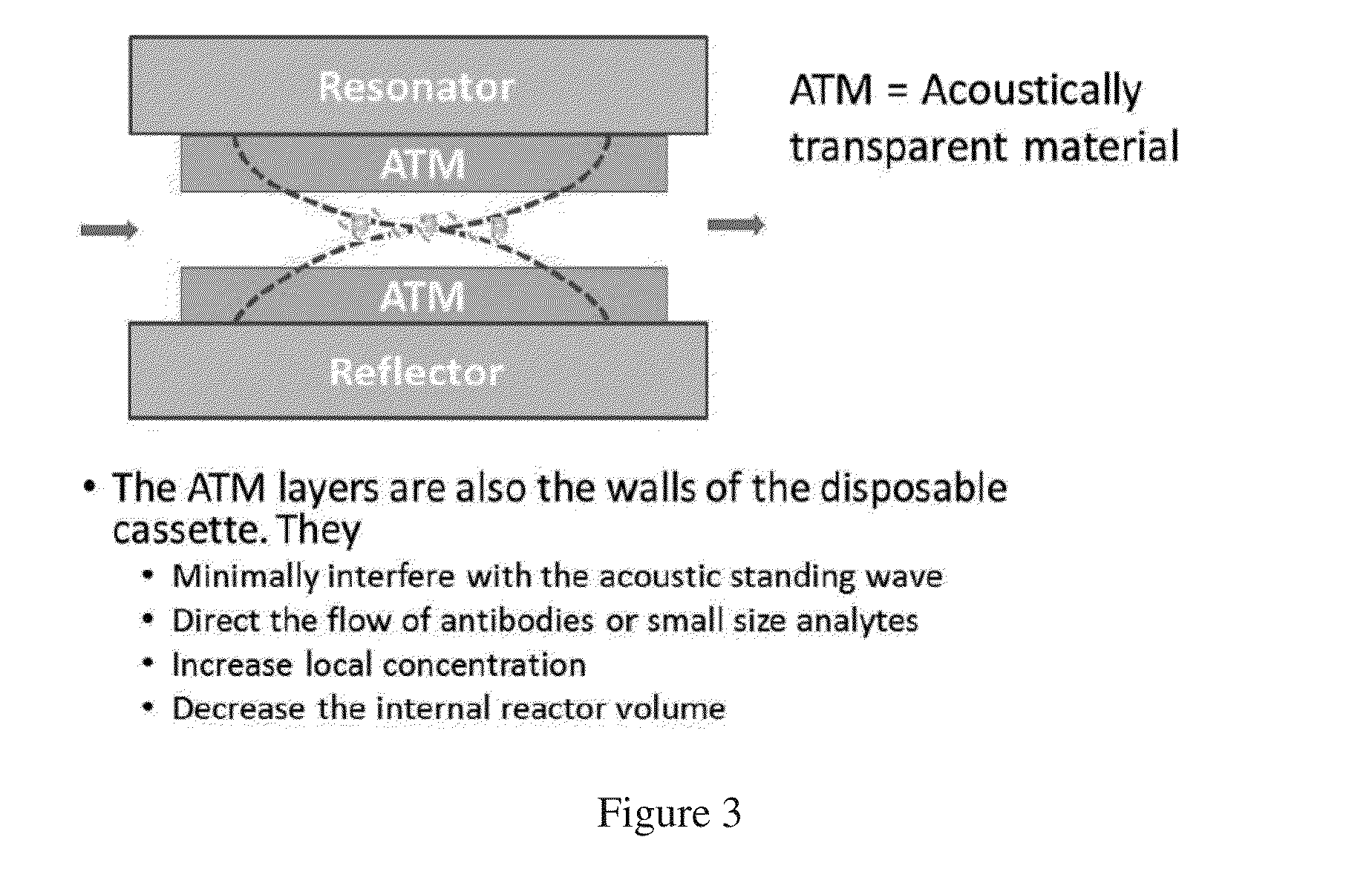

[0012]Described herein are fluidic (e.g., microfluidic and macrofluidic) devices and methods suitable for performing biochemical reactions on particles suspended in a liquid medium. Specifically, an acoustic standing wave is produced perpendicular to or at an angle to a flow path through a channel (e.g., a microchannel or macrochannel) and the suspended particles are held at a point, such as the center, in the channel (e.g., in a node or anti-node of the standing wave) when the liquid medium is flowed through the channel. Once the particles are held within the channel by the acoustic standing wave, one or more solutions containing the biochemical reactant(s) are flowed through the channel, allowing for binding of the biochemical reactant(s) with the held particles. Advantageously, reactions can be performed on the held particles in the absence of wall effects from the channel. Optionally, unreacted biochemical reactant is removed from the channel by flowing a wash solution through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com