Tubular-bag machine having a gas-adjusting device, and gas-adjusting device for such a tubular-bag machine

a tube-bag machine and tube-bag technology, which is applied in the field of tube-bag machines having gas-adjusting devices, can solve the problems of affecting the quality of tubular-bag machines, increasing the amount of packaging material for packagings being produced, and risking the displacement of products in packaging tubes, so as to save gas and reduce the amount of gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

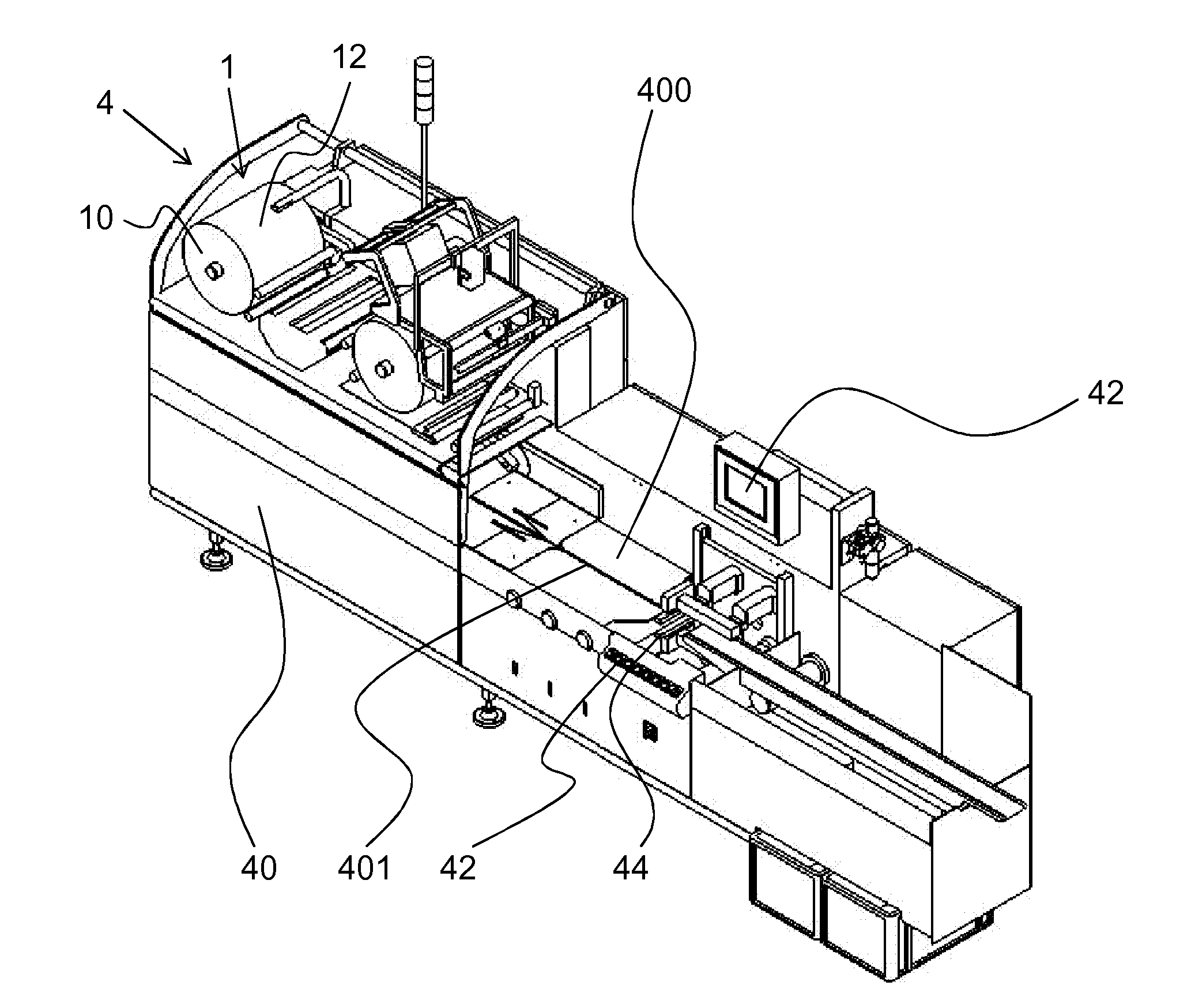

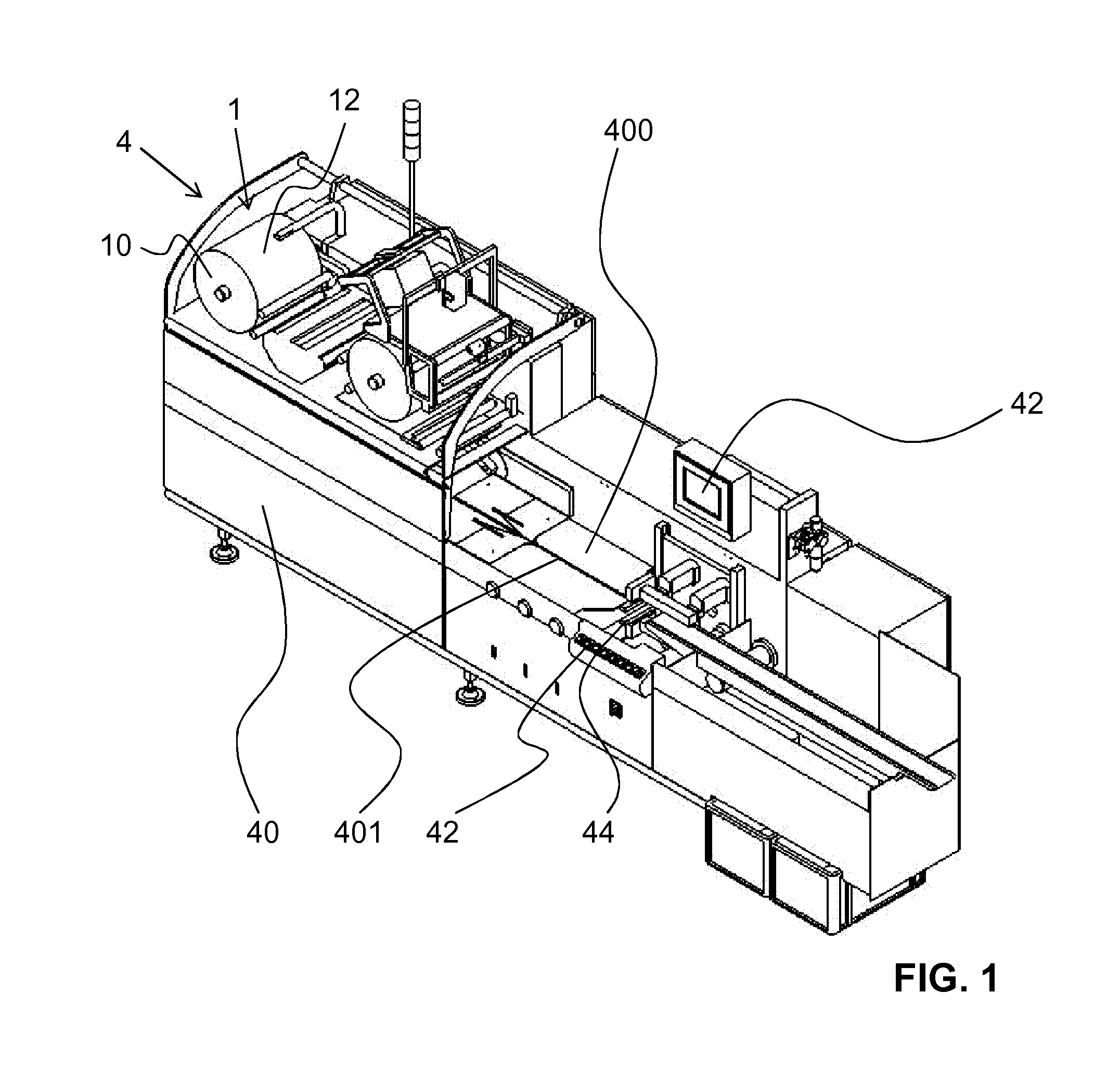

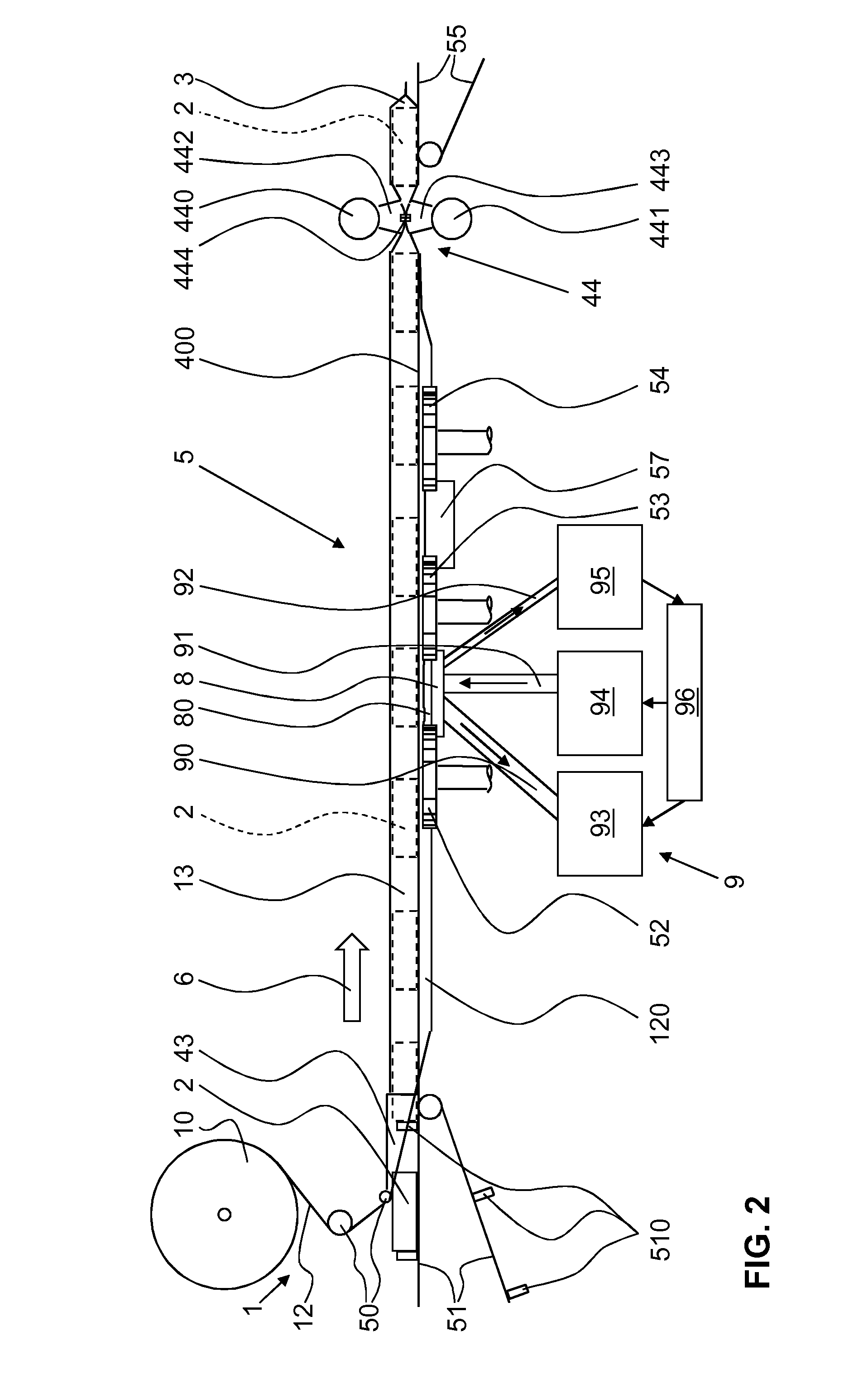

[0060]A horizontal tubular-bag machine is depicted in FIG. 1, as said machine is well known from the prior art. The tubular-bag machine 4 has a film roll 10 as packaging material 1. The film roll 10 contains a packaging sheet material 12.

[0061]The tubular-bag machine 4 comprises a frame 40 with operating and display elements 42 mounted thereon. A running surface 400, which has a longitudinal slot 401, is provided on the top side of the tubular-bag machine 4. The longitudinal slot 401 is used to accommodate the longitudinal sheet edge regions of the packaging sheet material 12 formed to a packaging tube during transport of the objects to be packaged along the longitudinal direction of the running surface 400. The tubular-bag machine 4 depicted in FIG. 1 furthermore comprises a longitudinal-connection device, which is not visible here and is disposed beneath the running surface 400, as well as a transverse-connection and separation device 44, which, in a known manner, welds the packag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com