Circuit board and method for manufacturing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

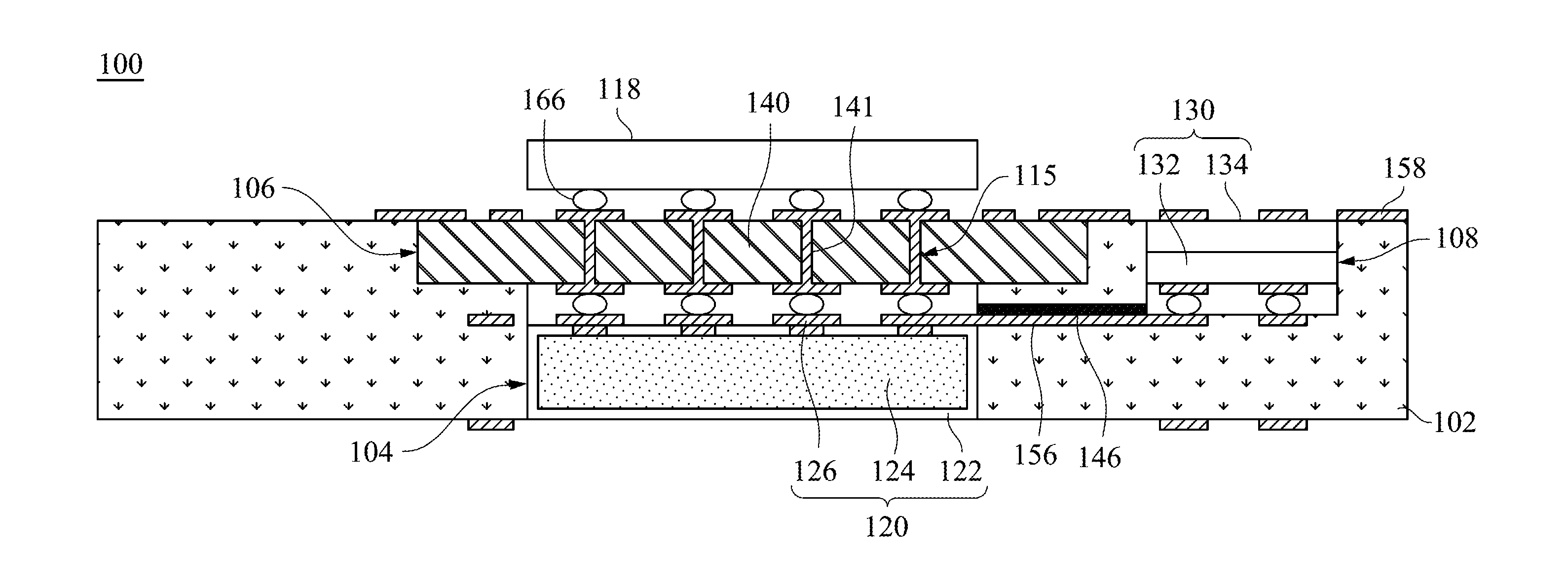

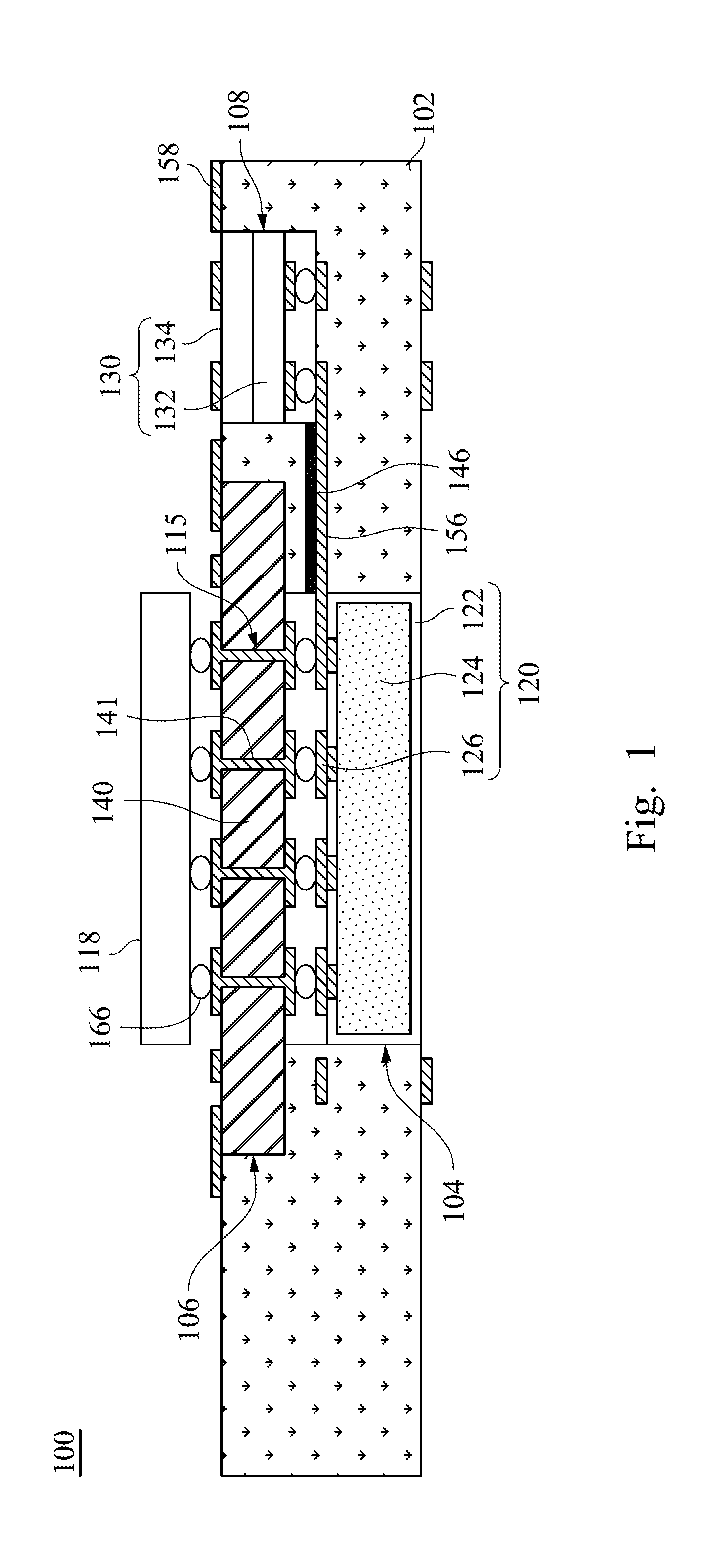

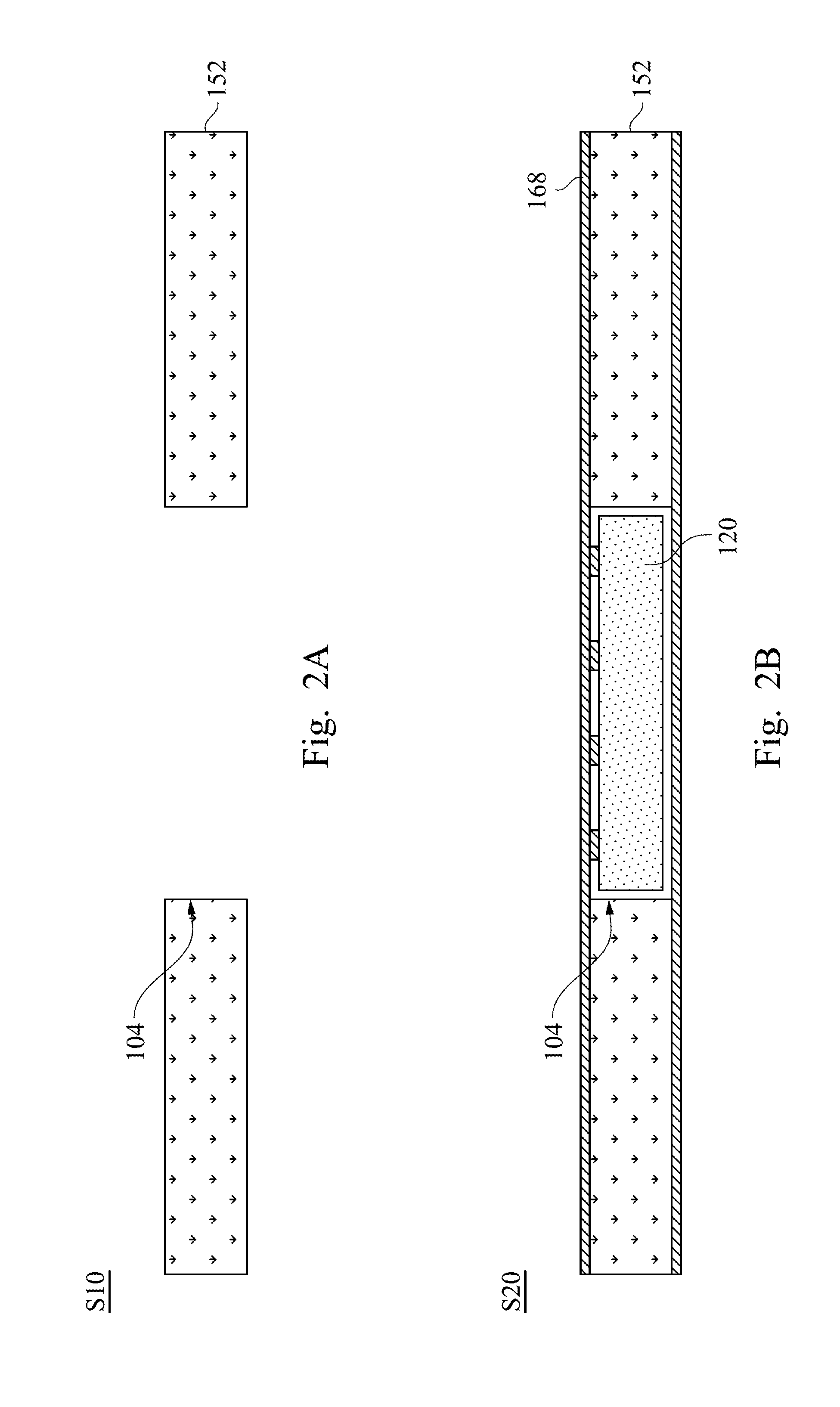

[0026]FIG. 1 is a schematic side view according to a circuit board 100 of this invention. A circuit board 100 with a heat-recovery function includes a substrate 102, a heat-storing device 120, and a thermoelectric device 130. The heat-storing device 120 is embedded in the substrate 102 and connected to a processor 118 for performing heat exchange with the processor 118. The thermoelectric device 130 embedded in the substrate 102 includes a first metal-junction surface 132 and a second metal-junction surface 134. The first metal-junction surface 132 is connected to the heat-storing device 120 for performing heat exchange with the heat-storing device 120. The second metal-junction surface 134 is joined with the first metal-junction surface 132, in which the thermoelectric device 130 generates an electric potential by a temperature difference between the first metal-junction surface 132 and the second metal-junction surface 134.

[0027]In the present embodiment, the processor 118 may be ...

third embodiment

[0053]In the present embodiment, a heat-conducting path is arranged in the vertical direction. However, according to a relationship between the positions of the circuit board 100 and the elements supplied the electrical energy by the thermoelectric device 130, a person having ordinary skill in the art may choose the proper arrangement of the circuit board 100 with the first, the second, or the

[0054]The circuit board 100 further includes a fixing frame 144. The fixing frame 144 is disposed in the second recess 112, in which the heat-storing device 120 is located in the fixing frame 144. The heat-storing device 120 further includes a third recess 114, in which the processor 118 is located in the third recess 114. The surfaces of the substrate 102, the fixing frame 144, the heat-storing device 120, and the processor 118 are coplanar. In other words, the fixing frame 144, the heat-storing device 120, and the processor 118 of the present embodiment are embedded in the substrate 102. More...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap