Rifle handguard with grip

a handguard and grip technology, applied in the field of forearm handguard assemblies, can solve the problems of poor grip and muscle fatigue, increased weight, inefficient cooling of the rifle barrel, etc., and achieve the effects of improving convective cooling of the firearm, improving grip, and reducing muscle fatigu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

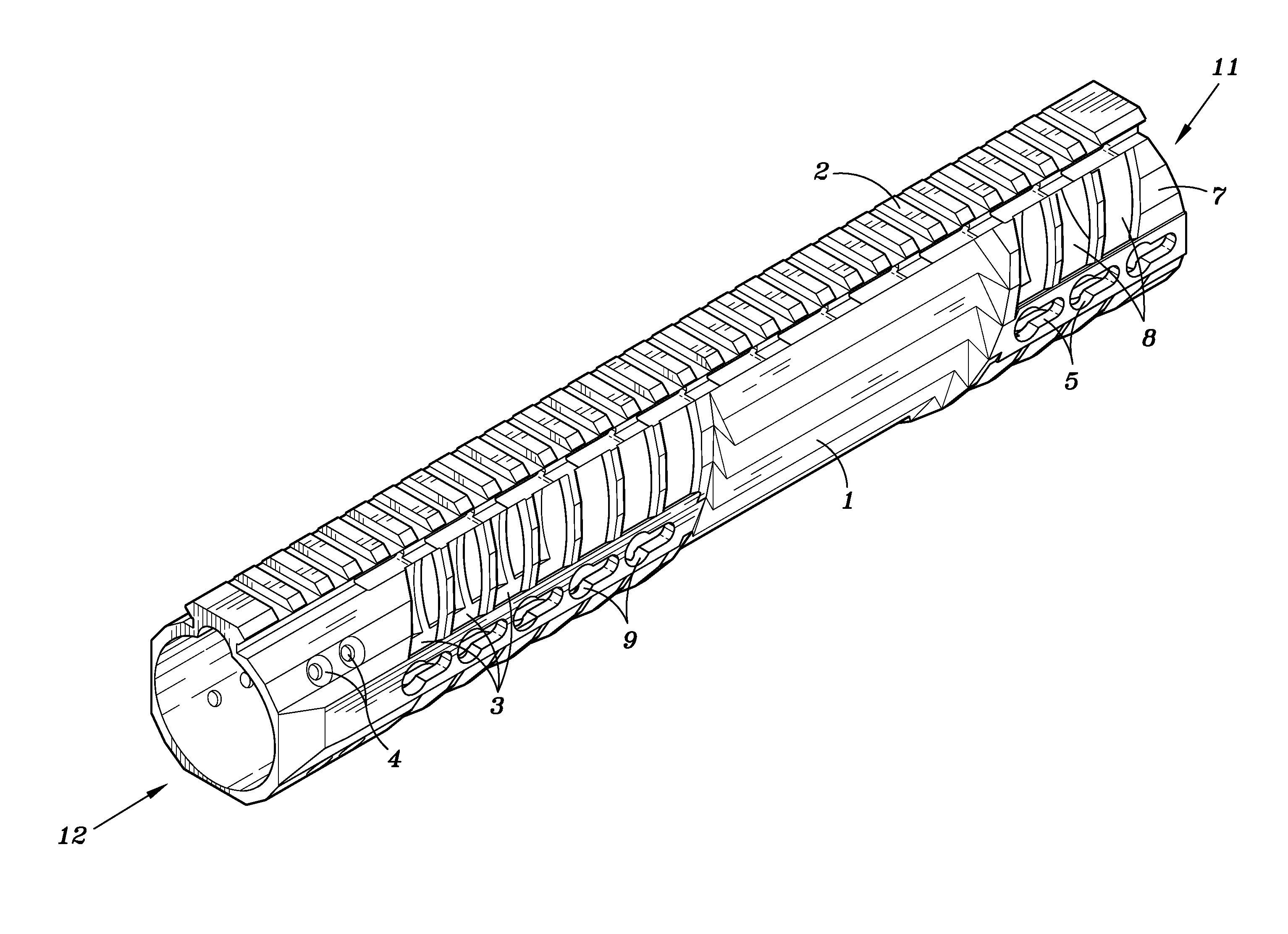

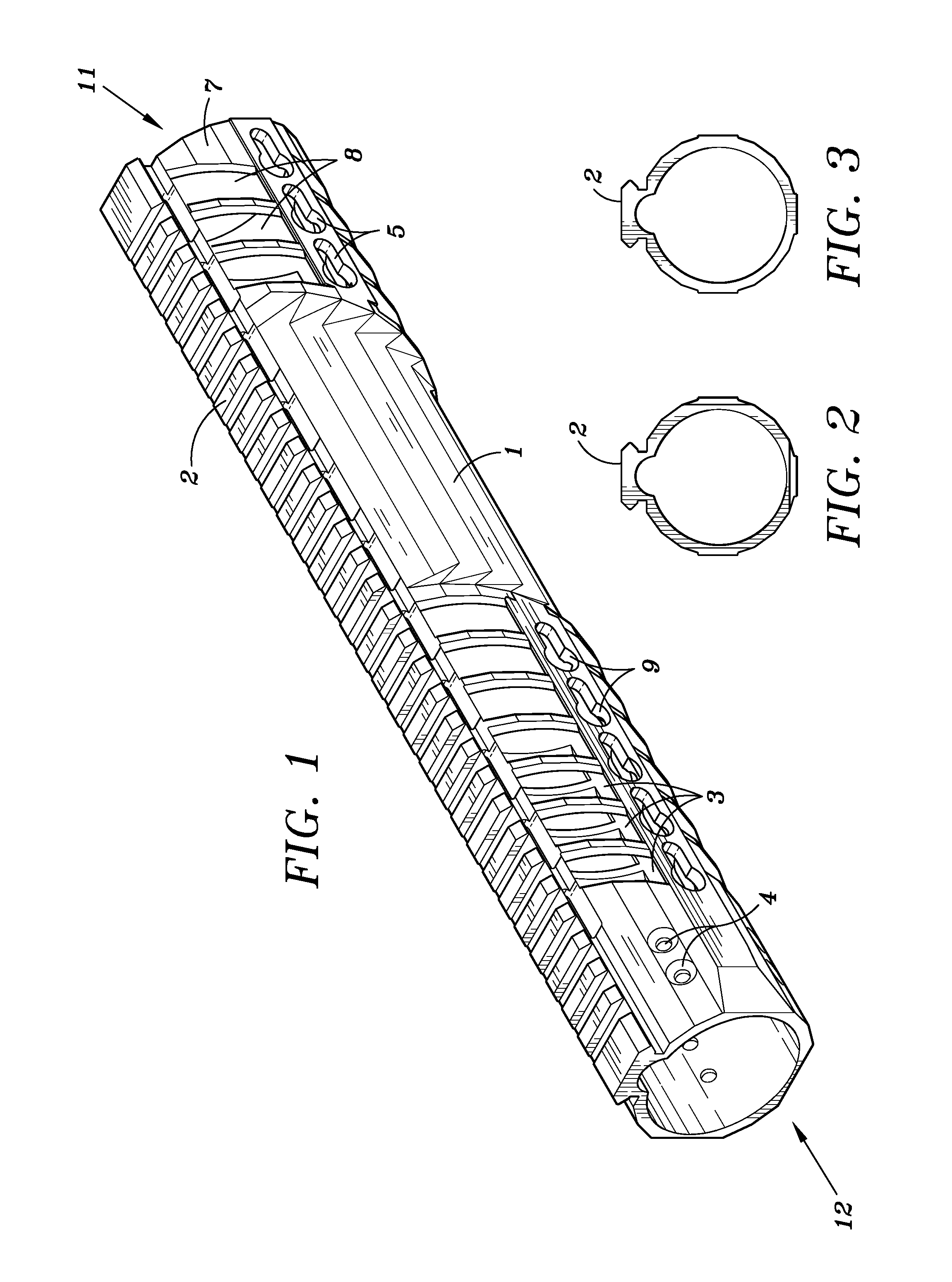

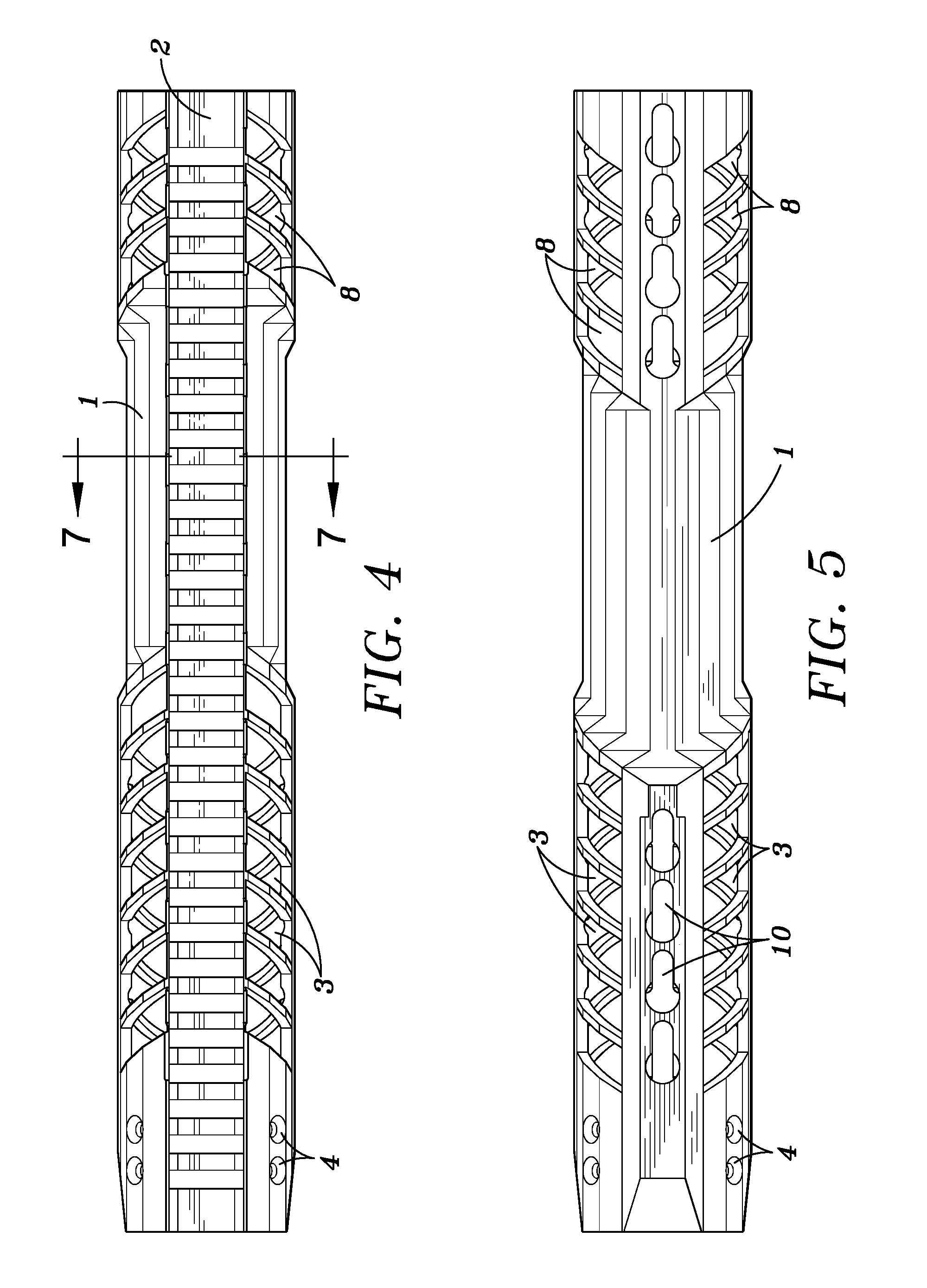

[0025]The present invention will be more fully understood and appreciated by reading the following Detailed Description in conjunction with the accompanying drawings, wherein like reference numerals refer to like components. FIG. 1 through FIG. 8 illustrate the gripping section and handguard of the present invention.

[0026]Referring to FIG. 1, an embodiment of the invention includes cylindrical member (7), gripping section (1), top mounting rail (2), forward ventilation cut-outs (8), rear ventilation cut-outs (3), screw holes (4), forward side bracket slots (5), rear side bracket slots (9), forward bottom bracket slots (6), and rear bottom bracket slots (10).

[0027]Cylindrical member (7) is a “free floating” handguard designed for a semiautomatic rifle. The “free floating” design is formed where the inner surface of cylindrical member (7) maintains radial spacing from the outer surface of the firearm barrel. As shown in FIG. 1, cylindrical member (7) has a cylindrical, tubular shape. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com