Electrolytic Hydrogen Generator and Method

a hydrogen generator and electrolysis technology, applied in the field of electrolysis, can solve the problems of difficult to achieve low resistance, and achieve the effects of less voltage, low resistance, and reduced current flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

case 6

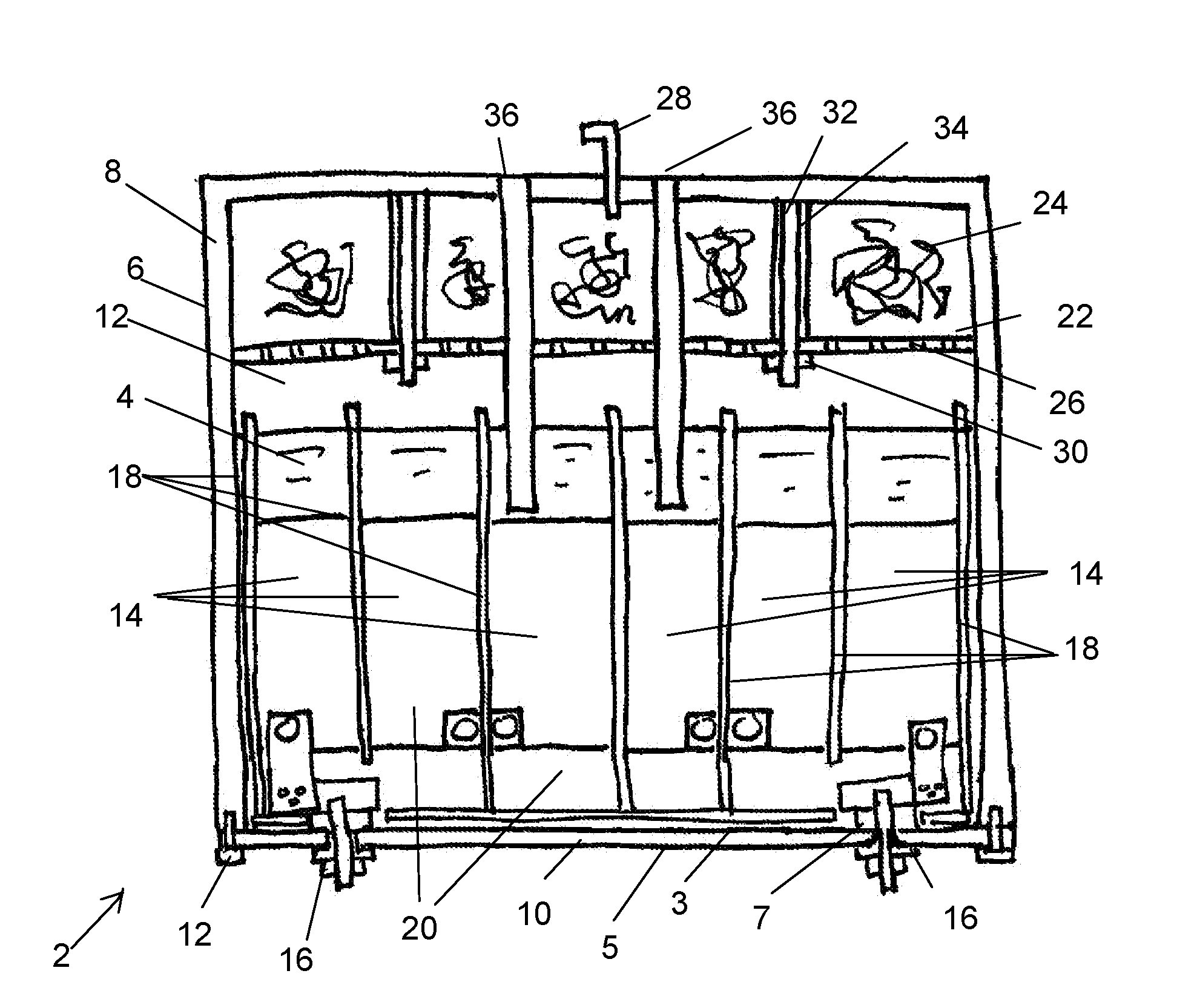

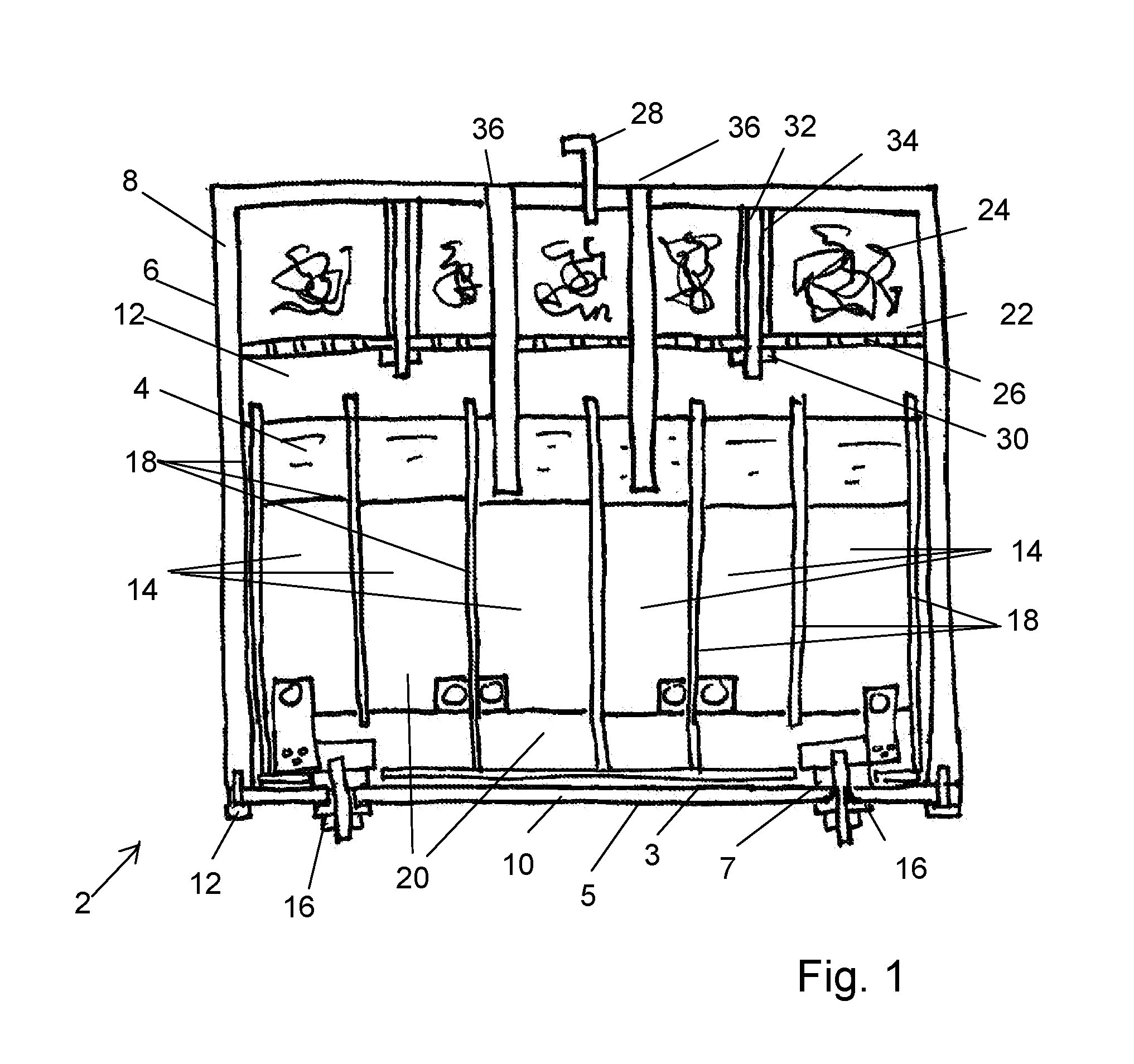

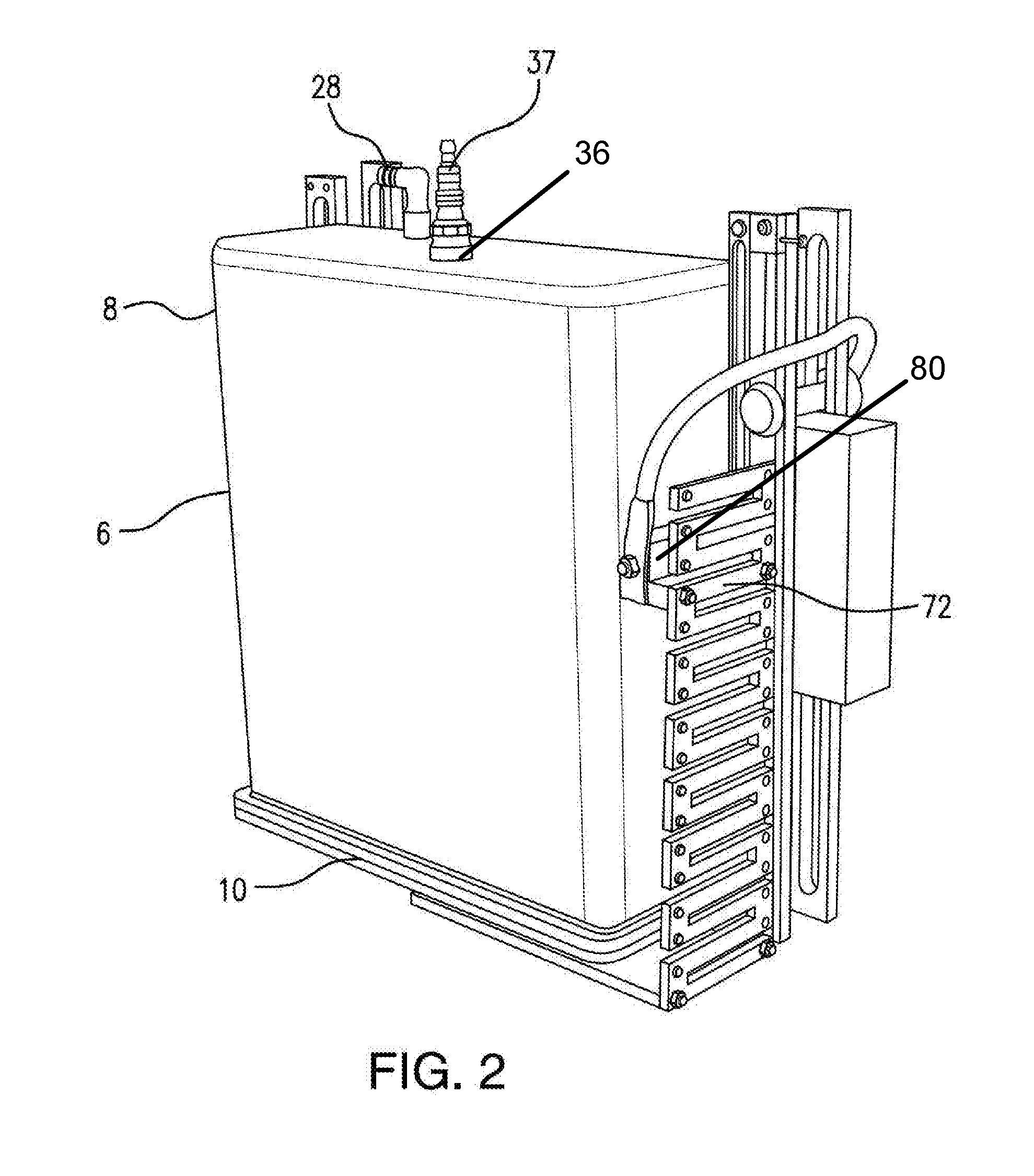

[0157]Electrolytic hydrogen generator 2 or HHO generator 2[0158]Inside 3[0159]Electrolyte 4[0160]Outside 5[0161]Case 6[0162]First and second electrode penetrations 7[0163]Body 8[0164]Interior volume 9[0165]Lid 10[0166]Bolts 11[0167]Hydrogen gas 12[0168]Cores 14[0169]Electrode assembly 16[0170]Plastic plates 18[0171]Chamber 20[0172]Separator plate 22[0173]Stainless steel wool 24[0174]Perforations 26[0175]Nuts 30[0176]Studs 32[0177]Stand-offs 34[0178]Penetrations 36[0179]First and second sets of core plates 38[0180]First and second core connector 40[0181]First and second elongated core fastener (bolt) 42[0182]A corner, a first corner 43[0183]First and second washers 44[0184]An opposing corner, a second corner 45[0185]A clearance cutout 46[0186]A core perforation 47[0187]Non-conducting core plate connector 48[0188]Non-conducting nut 50[0189]A connecting hole 51[0190]Non-conducting spacer 52[0191]Three-dimensional rectangular shape 53[0192]Electrical current flow 54[0193]HHO 56[0194]A f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resistance | aaaaa | aaaaa |

| DC voltage | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com