Fuzzy curve analysis based soft sensor modeling method using time difference Gaussian process regression

a soft sensor and fuzzy curve technology, applied in the field of complex, can solve the problems of inability to fully explain the characteristics of the process, inability to meet the causality, and significant time lag between the input data collected by each sensor and the output data, so as to reduce production costs, increase yield, and improve accuracy. the effect of results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

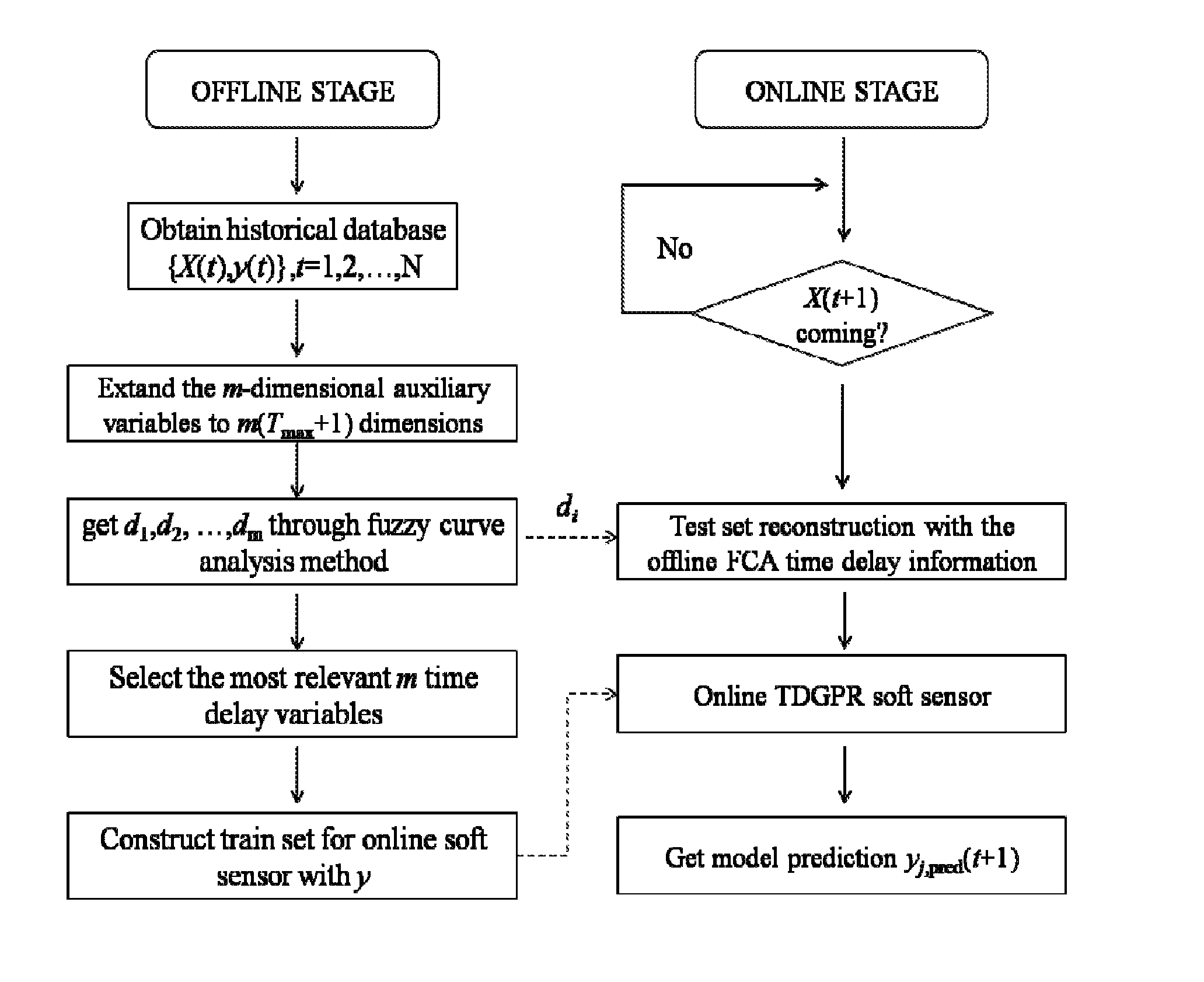

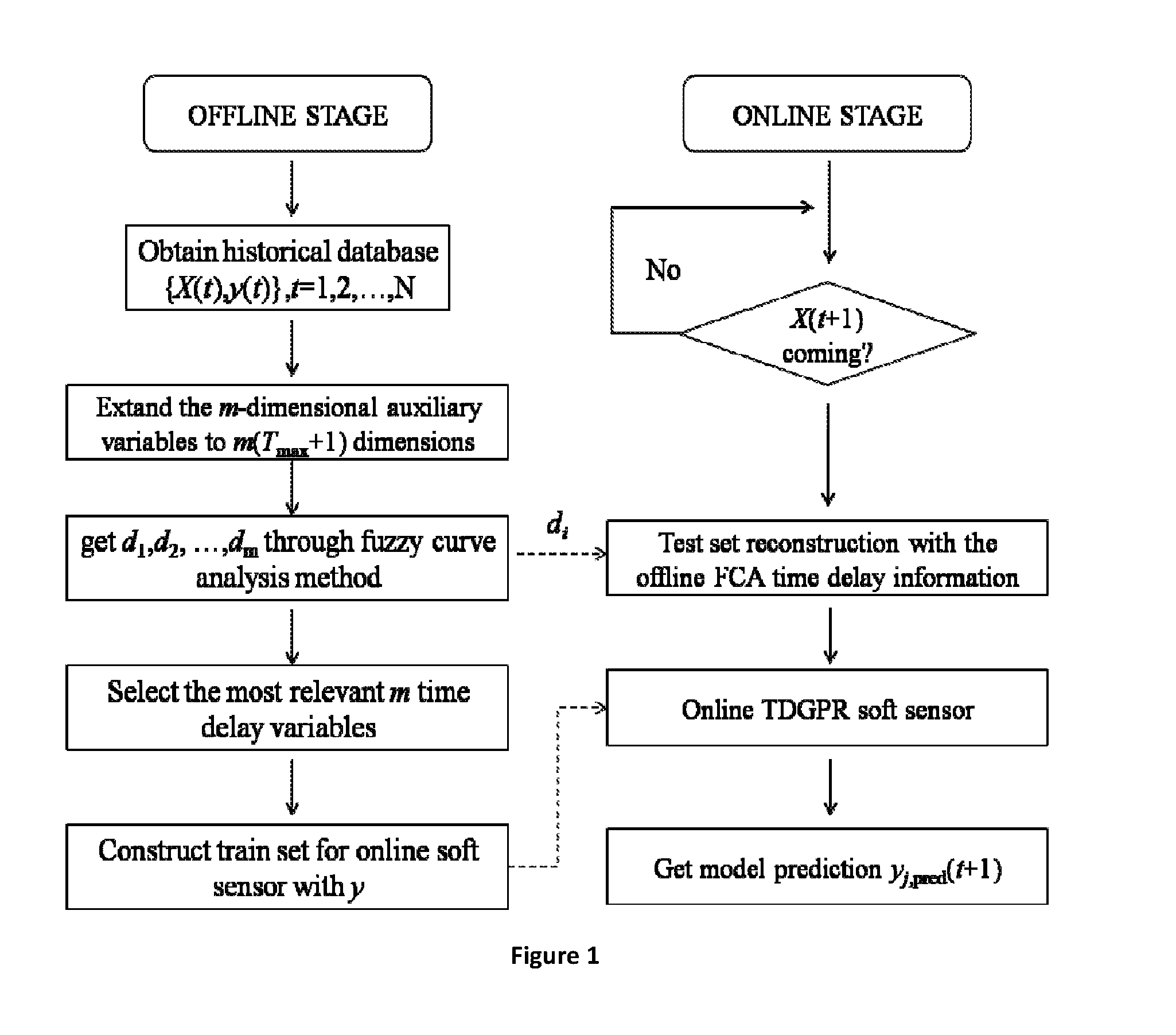

[0020]The modeling flow chart, which is shown in FIG. 1 below, is further detailed in the present invention:

[0021]Take the actual chemical process as an example, debutanizer is an important part of naphtha desulfurization and separation device of oil refining production process, and one of the dominant variables needed to be controlled for this process is the concentration of the bottom butane (C4). The schematic diagram of the process is shown in FIG. 2, due to the value of C4 cannot be directly measured, therefore, there is a delay issue in analyzing and obtaining C4 concentration values. At the same time, different auxiliary variables show different degrees of time delay. Experimental data is derived from the actual industrial process which contains 2394 samples, a total of 7 auxiliary variables. As shown in FIG. 2, x1 is the top temperature; x2 is the top pressure; x3 is the reflux flow; x4 is the top product outflow; x5 is the 6th tray temperature; x6 is the bottom temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com