Downhole well conditioning tool

a well-conditioning and downhole technology, applied in the field of oil and gas wells, can solve the problems of ineffectiveness, drawbacks, and perforations that have to be cleaned out, and achieve the effects of improving oil recovery, improving fluid dispersion and mobilization, and enhancing fluid recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

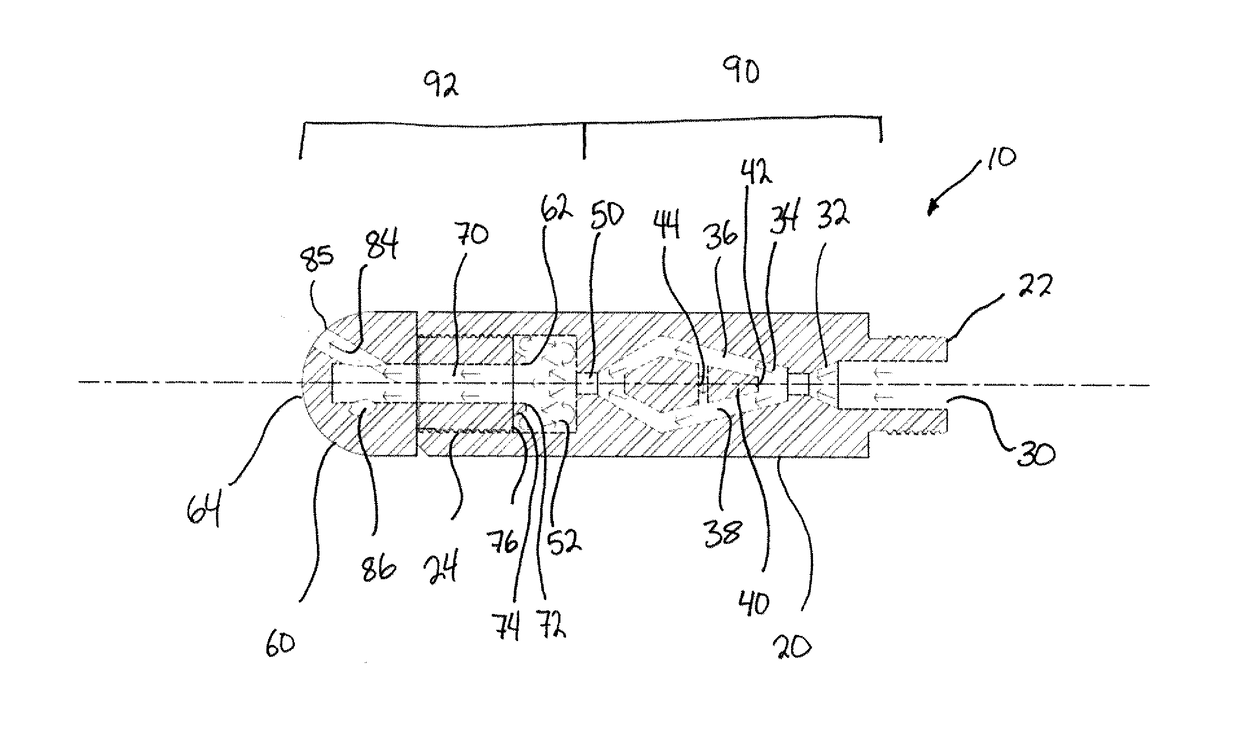

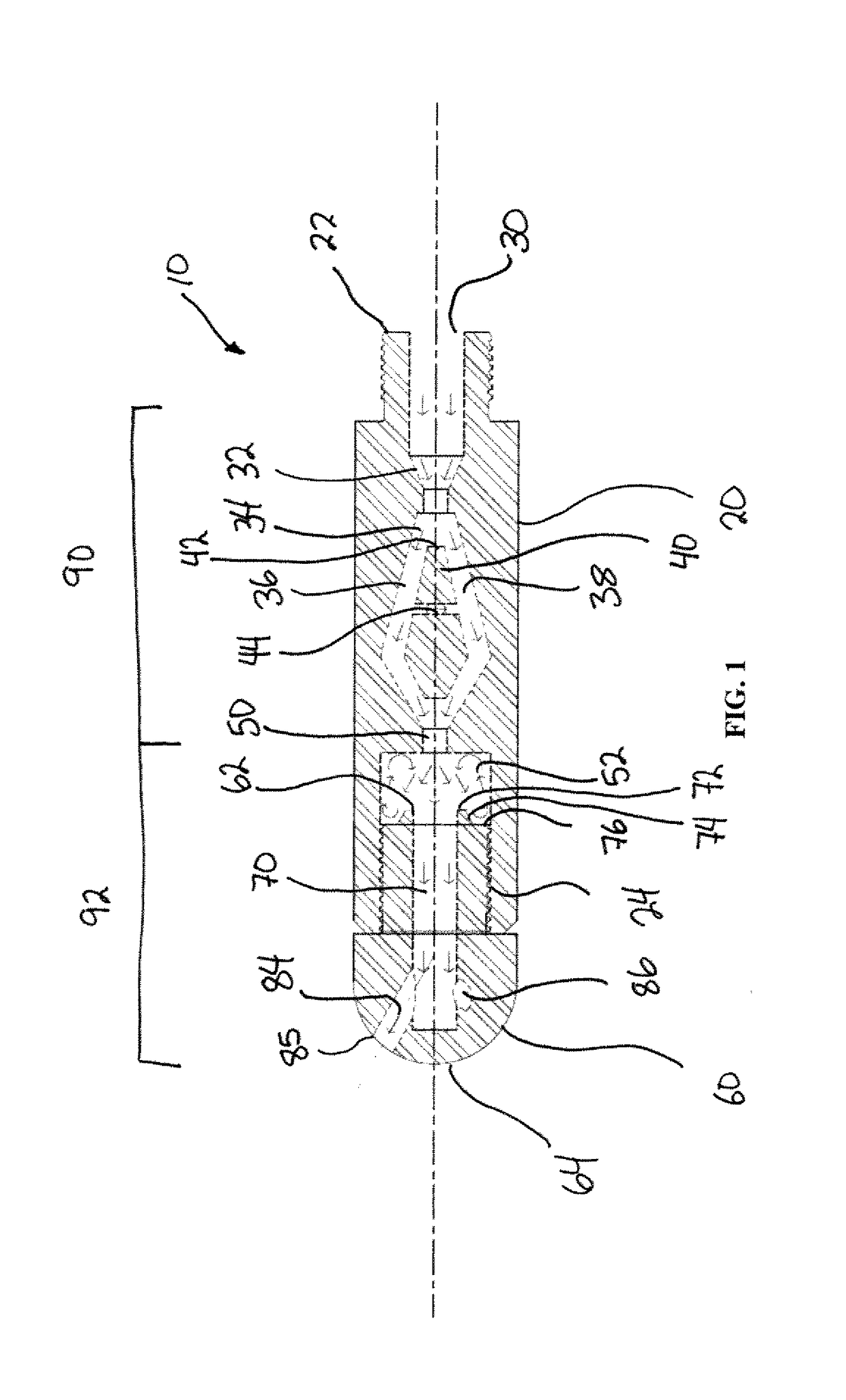

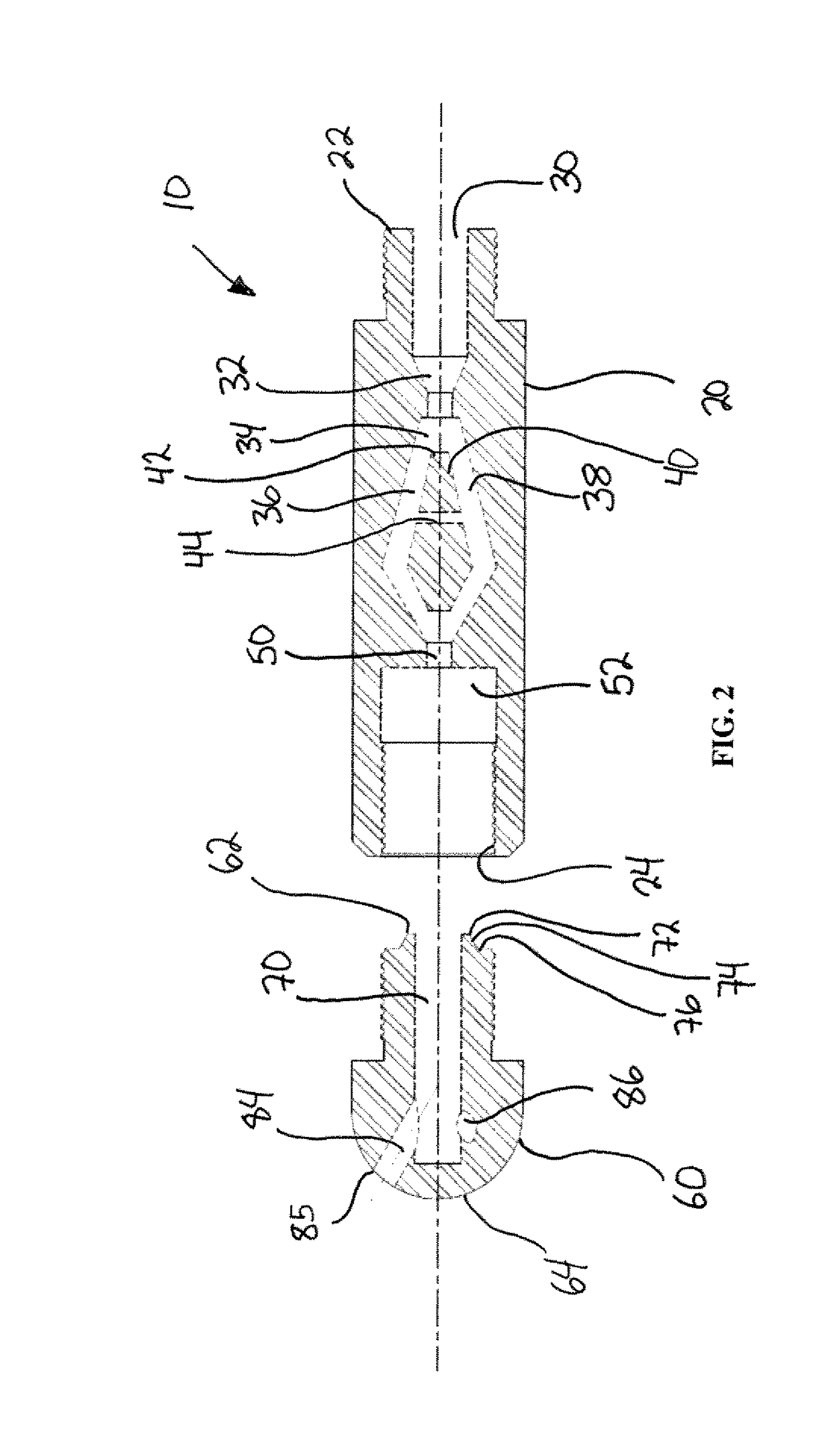

[0020]FIGS. 1 and 2 illustrates a well tool 10 that is used down hole and can self-create pulsating fluid streams for well cleaning and stimulation. The well tool 10 can be suspended downhole in a well (not shown), such as an oil well. Typically, the well tool 10 will be suspended downhole on a running string, as a drop tool, or coiled tubing configuration running to the ground surface. Pressurized fluid can be forced down the running string or coiled tubing into the well tool 10 where the pressurized fluid stream will be self-excited in the well tool 10 before exiting the well tool 10 through outlet ports 83, 85, 87 as pulsating pressurized fluid streams to contact the inside surfaces of the well and also displace fluid distally in both the near well bore and the peripheral reservoir.

[0021]In a typical application, the well tool 10 can be lowered downhole so that the well tool 10 is located at a point in the well where perforations have been made in the casing of the well. These pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com