Flexure-based system for measuring torque on a shaft

a technology of flexure and torque, which is applied in the direction of magnetic measurement, measurement devices, instruments, etc., can solve the problems of high cost of mass production market devices and expensive implementation, and achieve the effects of reducing the stress of flexure, preventing overloading of flexure beams, and increasing the amount of flux presen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013]In the following detailed description of the invention, certain preferred embodiments are illustrated providing certain specific details of their implementation. However, it will be recognized by one skilled in the art that many other variations and modifications may be made given the disclosed principles of the invention.

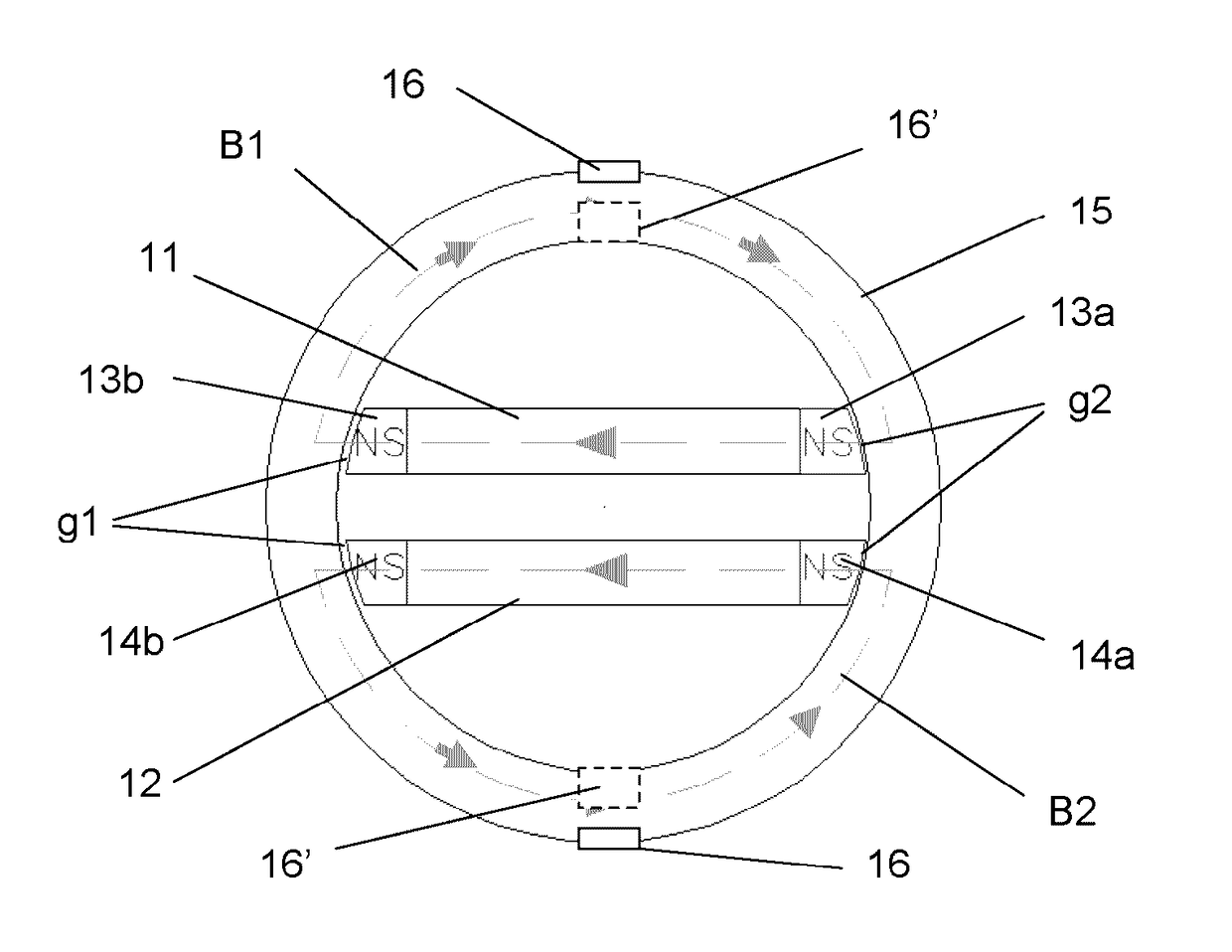

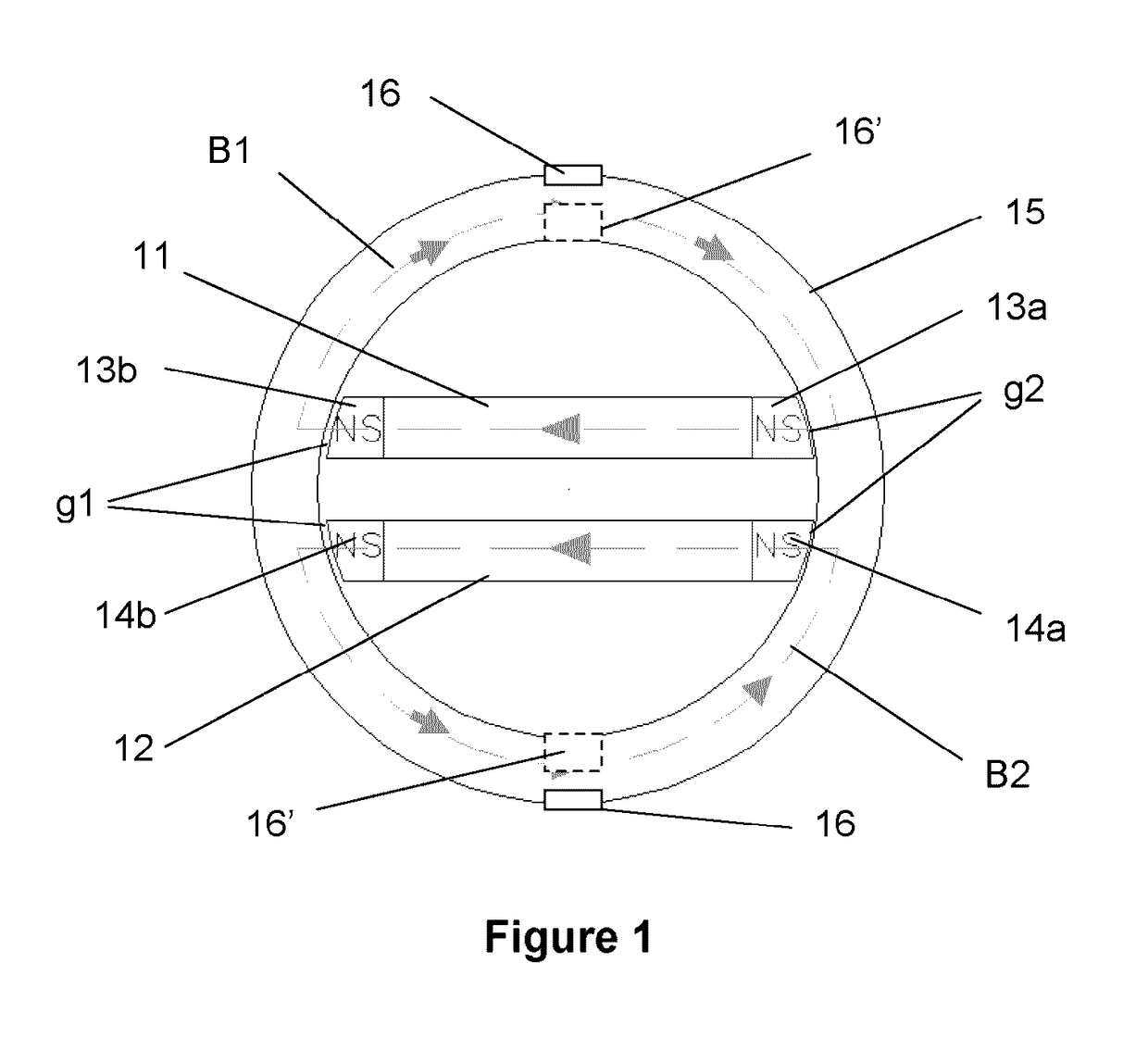

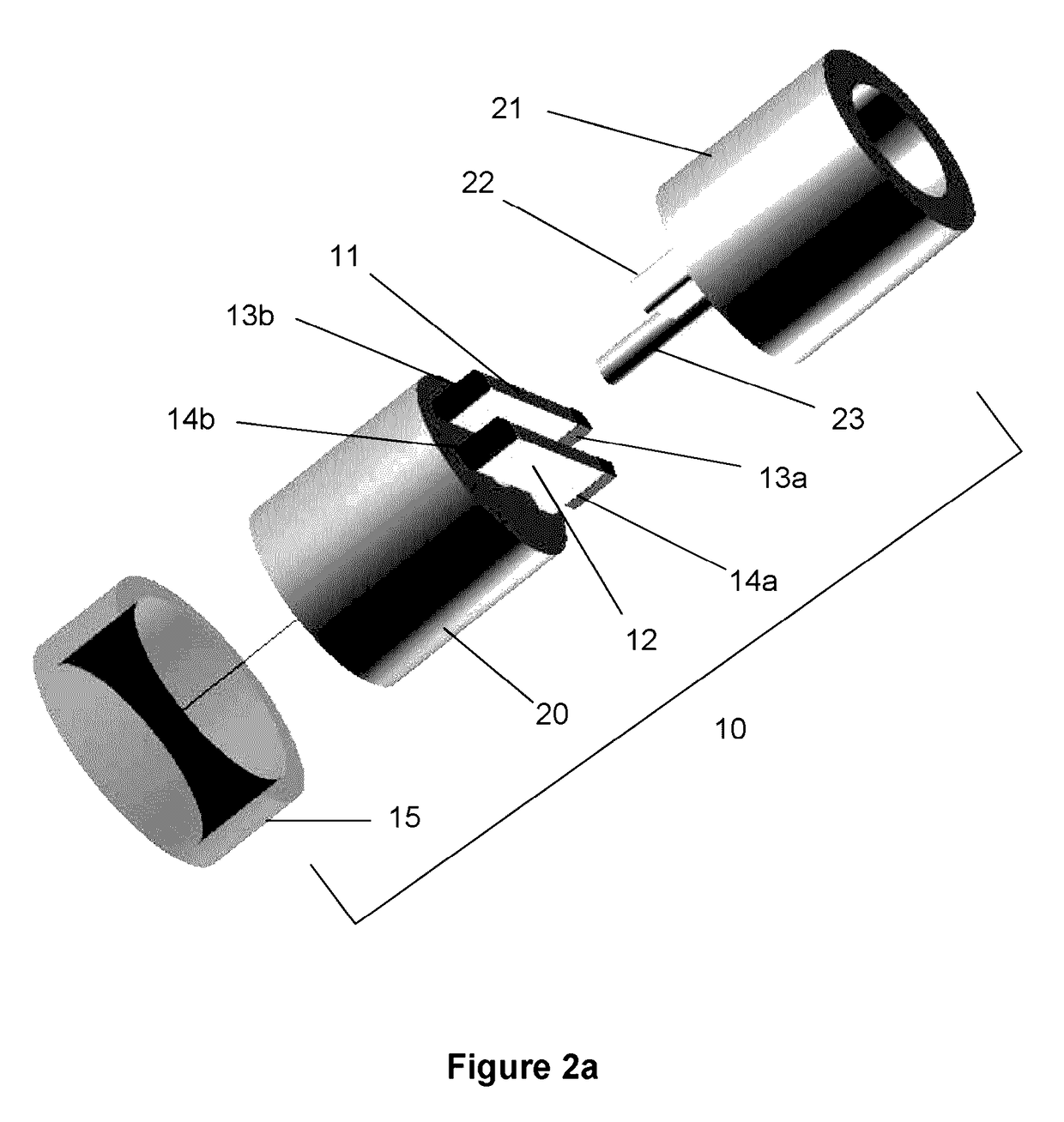

[0014]Referring to the schematic view shown in FIG. 1, the sensor 10 has two flexure beams 11, 12 with magnet pairs 13, 14 attached and configured (pole-wise), as shown. The magnets 13a, 13b and 14a, 14b are attached such that opposing poles are in contact with the flexure beams 11 and 12, respectively. So, for example, if first magnet 13a is mounted with its North pole in contact with flexure beam 11, at the opposite end, second magnet 13b will be mounted with its South pole in contact with the beam. It is necessary that the N-S arrangement, with respect to the flexure beams 11 and 12, stay the same for both beams. The magnets 13a, 13b, 14a and 14b may be of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

| dimensions | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com