Steam Turbine Plant

a steam turbine and plant technology, applied in steam engine plants, leakage prevention, machines/engines, etc., can solve the problems of reducing the efficiency of the gas turbine (heat source device) and the rated load so as to reduce the differential effectively using the heat in the plant, and reducing the thermal expansion of the steam turbine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0025]Control means for controlling the amount of heat input to a steam turbine and a steam turbine plant having this means according to the invention will be described with reference to drawings.

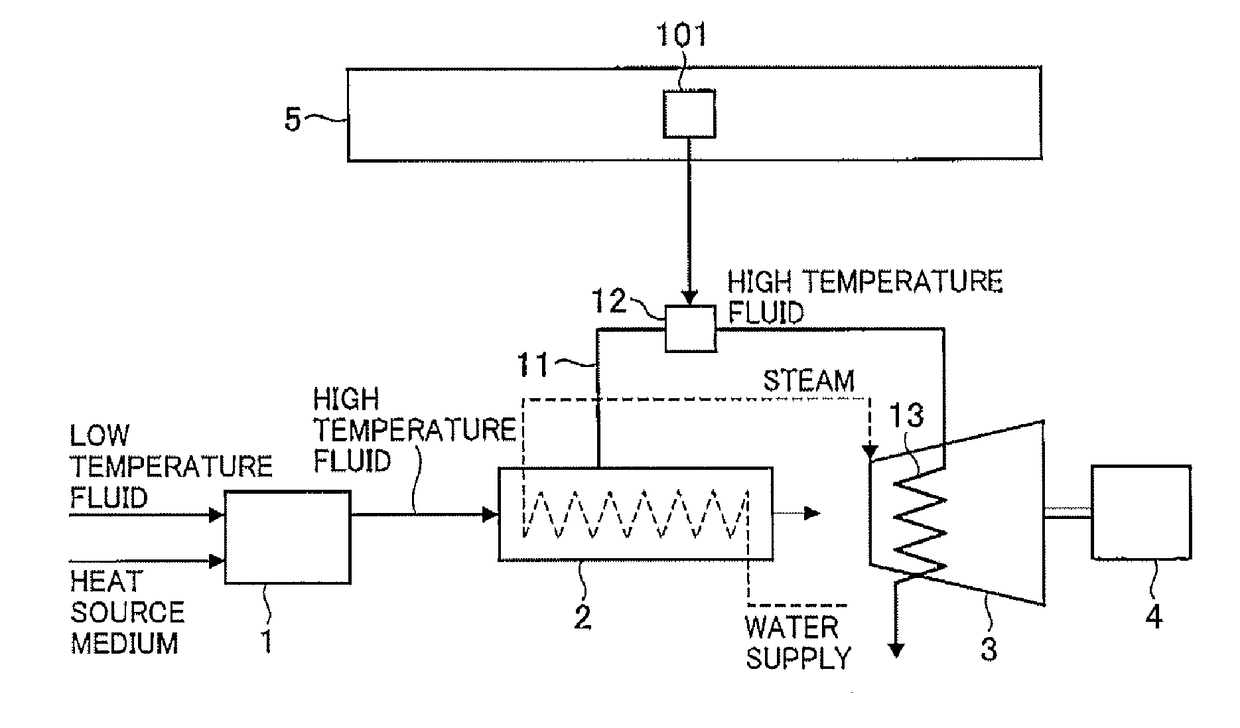

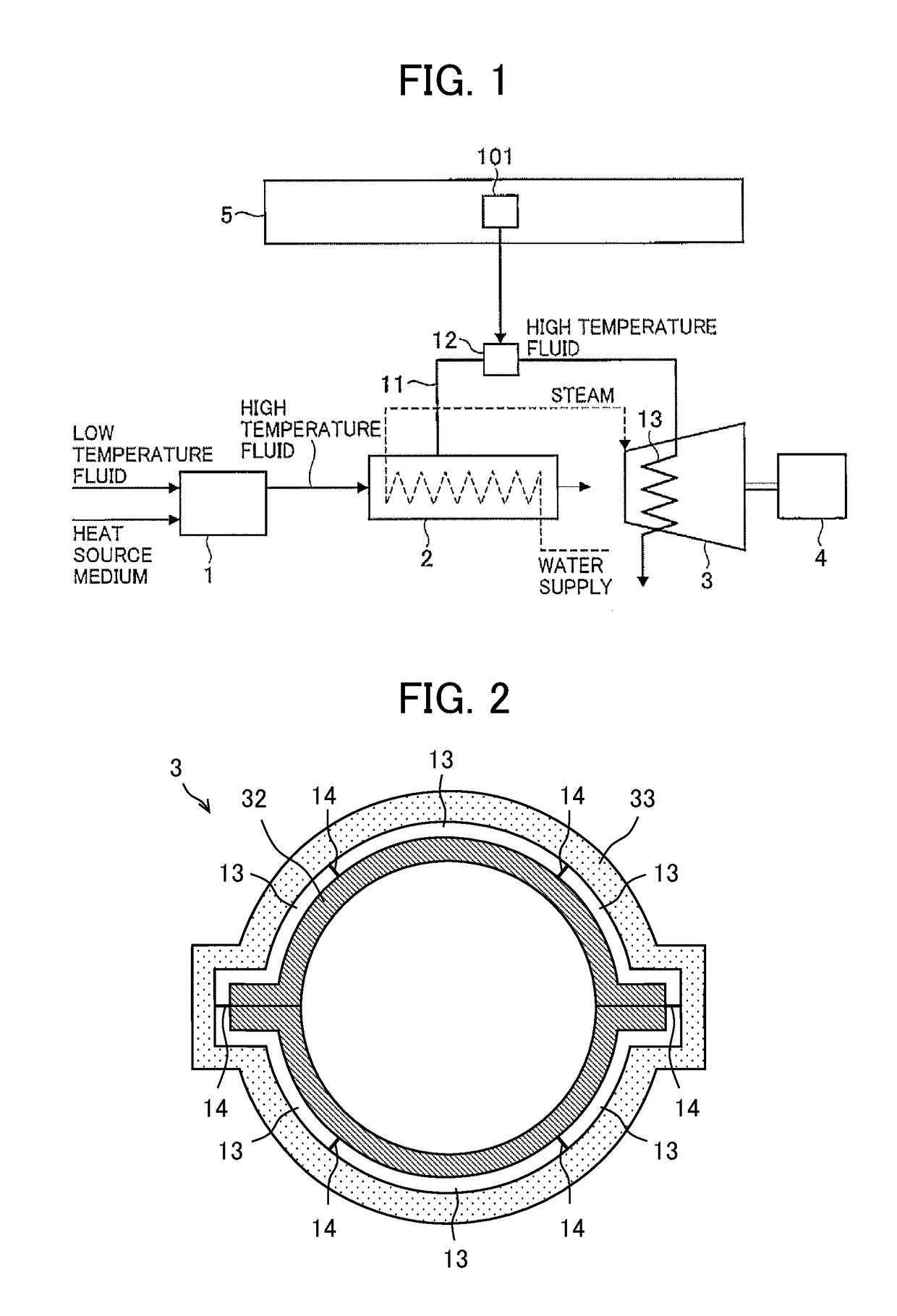

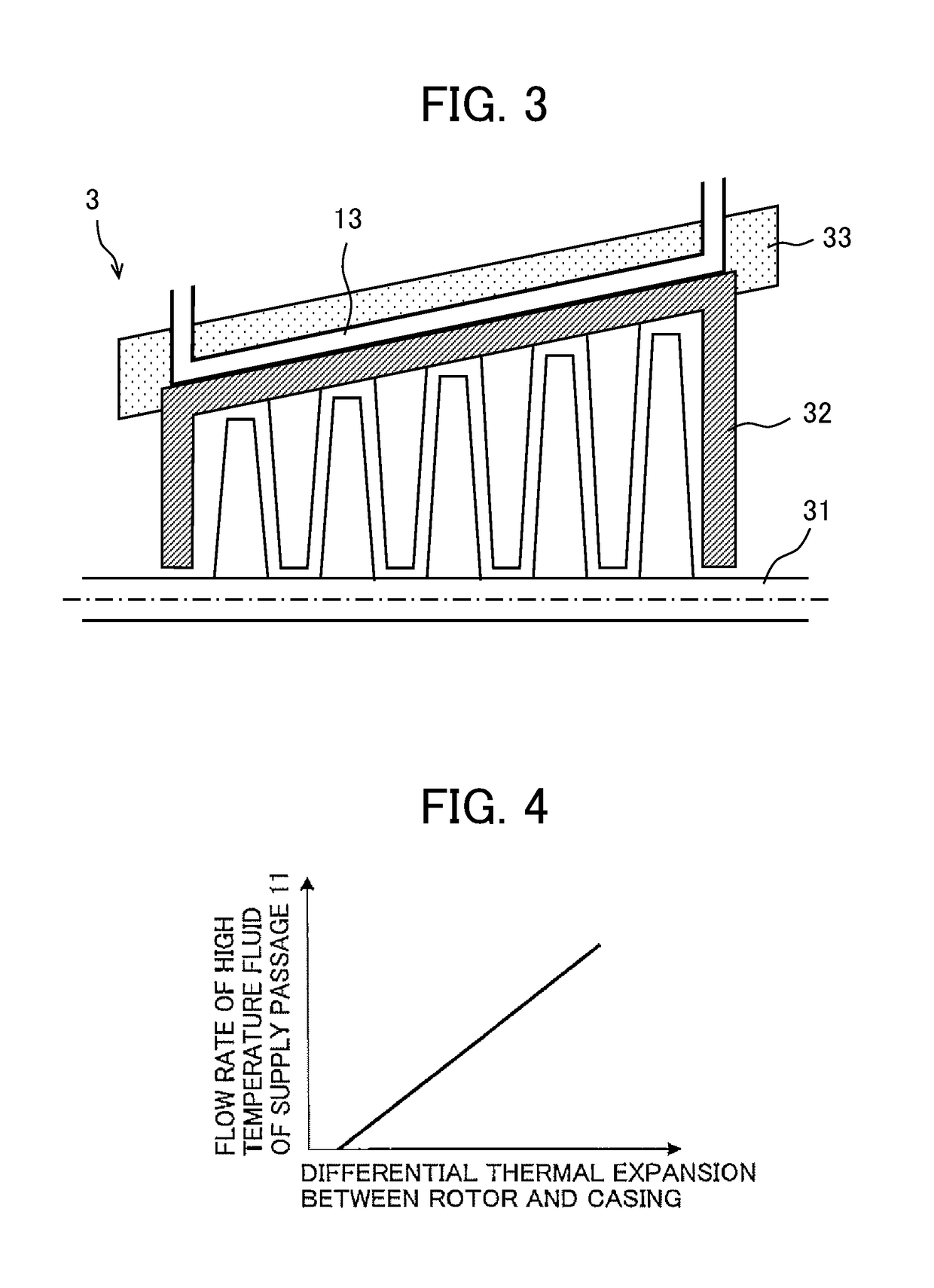

[0026]FIG. 1 is a schematic diagram illustrating a configuration of the steam turbine plant according to the embodiment. In FIG. 1, only configuration components and control circuits required for describing the invention are illustrated. FIG. 2 is a cross-sectional view in a turbine radial direction illustrating a schematic structure of a heating flow path of a casing of a steam turbine according to the embodiment, and FIG. 3 is a cross-sectional view in a turbine axial direction. In FIG. 2, drawings of a rotor, a moving blade, and a stationary blade are omitted, and in FIG. 3, only an upper half side of a turbine is illustrated.

[0027]The steam turbine plant of the embodiment is provided with a heat source device 1, a steam generating device 2, a steam turbine 3, a generator 4, and a plant ...

second embodiment

[0054]Although a case in which the cooling flow path 23 is disposed on the portion of the lower half of the casing 32 as the portion to be the relatively low temperature at the time of starting the plant is described as an example in the second embodiment, without being limited thereto, arrangement and number of the cooling flow path 23 may be determined by the analysis of the empirical knowledge or the known method of the heat transfer engineering. That is, the cooling flow path may be disposed on the upper half side of the casing 32 as the portion to be relatively low temperature, at the time of starting the plant. In addition, at the time of starting the plant, if the portion to be relatively low temperature and the portion to be the relatively high temperature is replaced, the cooling flow path and the heating flow path may be replaced. In such a case, it is possible to obtain the same effect as described above.

[0055]Although a case in which the heating flow path 13 is disposed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com