Canister for vehicle having auxiliary canister

a technology for canisters and vehicles, applied in machines/engines, separation processes, transportation and packaging, etc., can solve problems such as the generation of harmful gases, such as hydrocarbons, and achieve the effect of reducing bleed emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Hereinafter, a canister for a vehicle having an auxiliary canister, according to an embodiment of the present invention, will be described in detail.

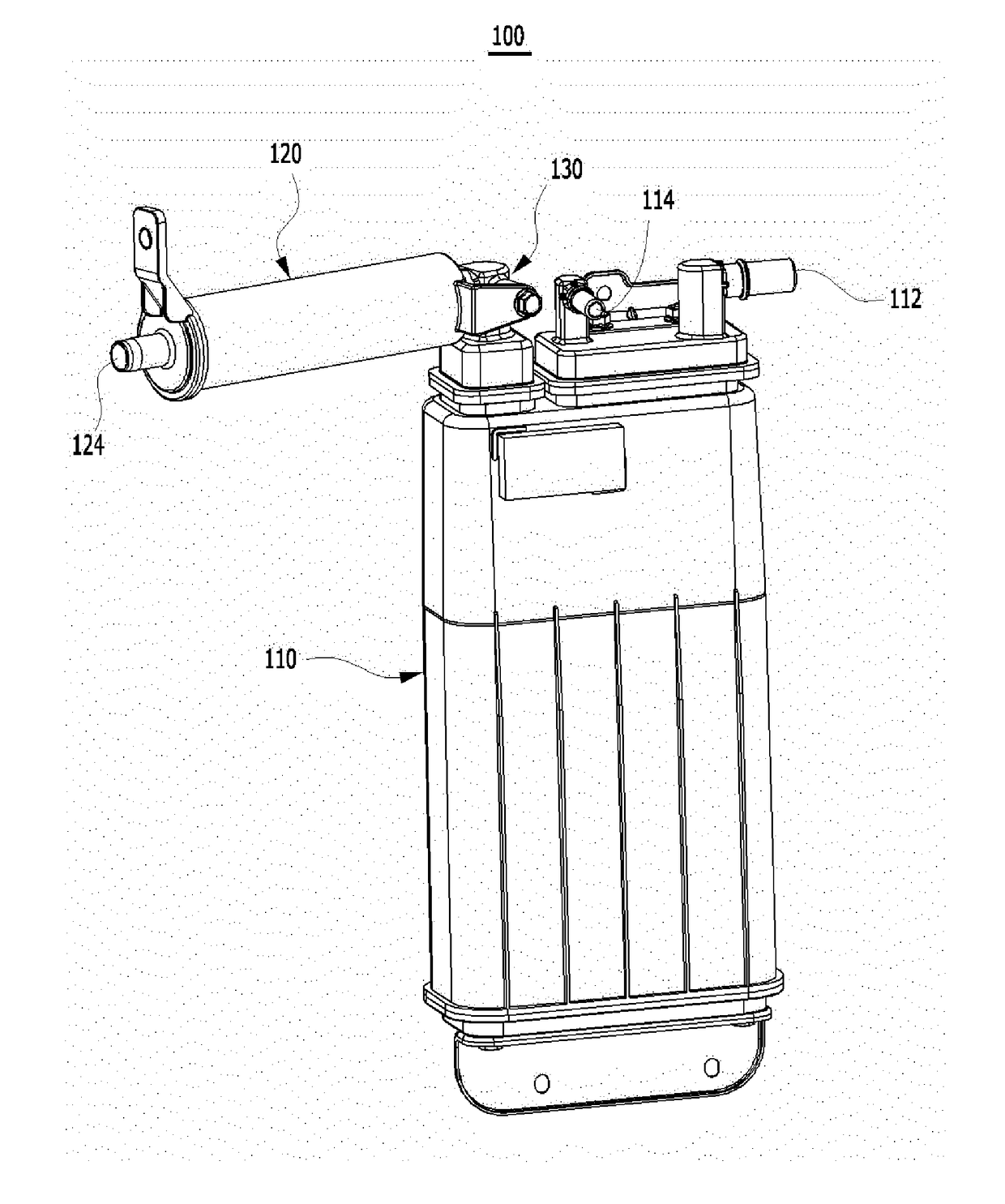

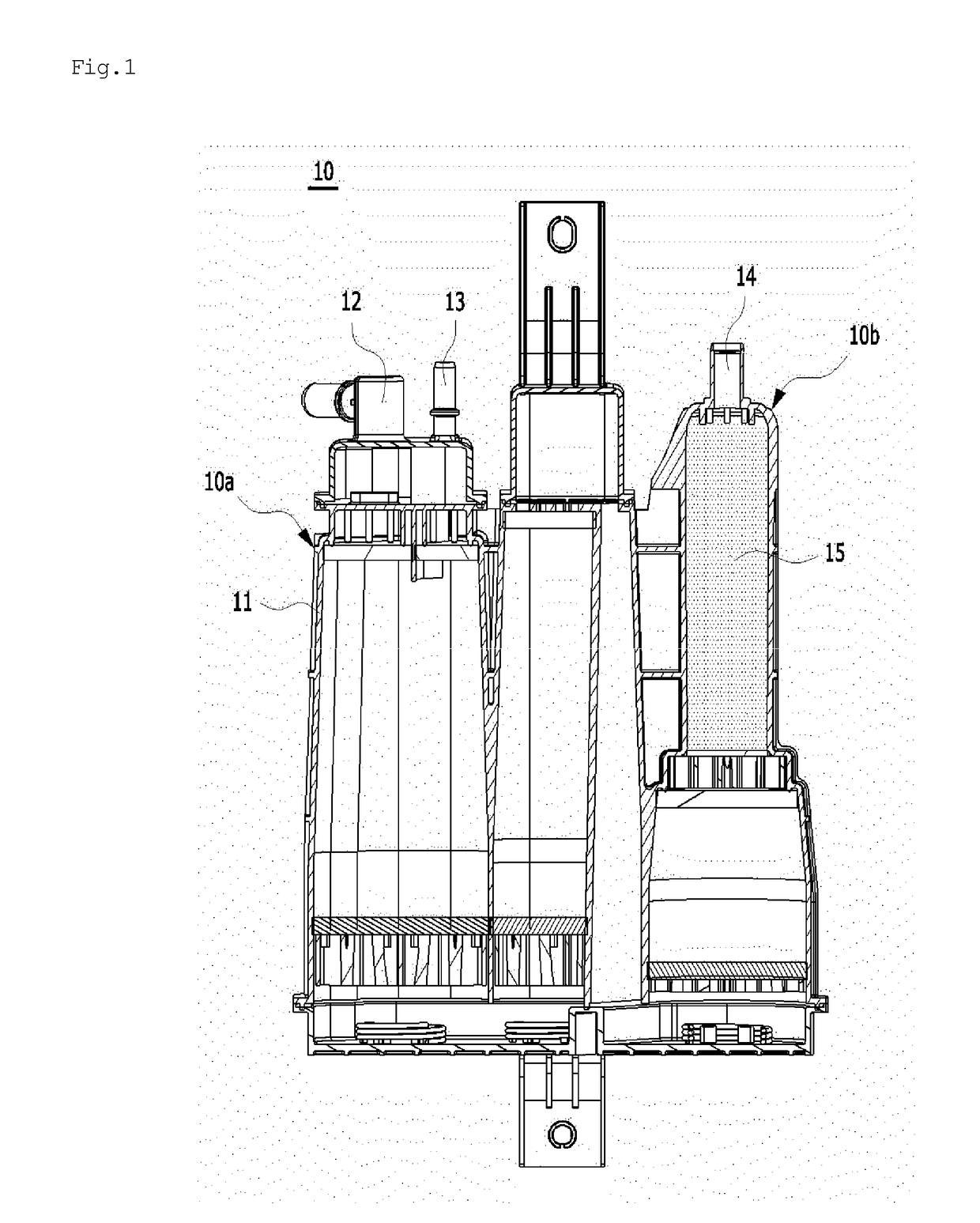

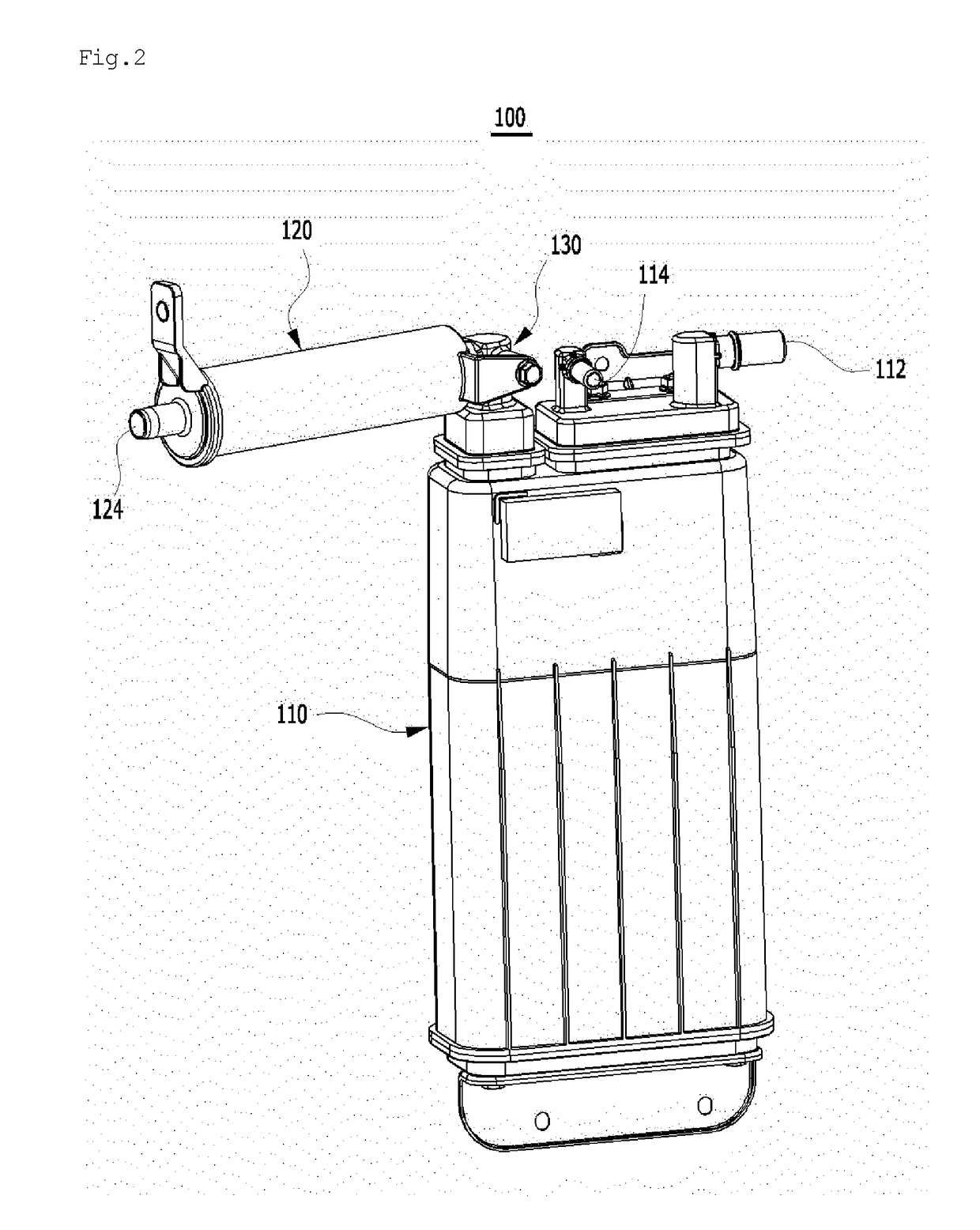

[0032]The canister 100 for a vehicle, which has the auxiliary canister, according to the embodiment of the present invention, in which the auxiliary canister 120 is provided on a side of the main canister 110 and a second trapping member 122 formed of a plastic material, to which an adsorbent material is applied, is installed within the auxiliary canister 120, may prevent a ventilation resistance increase generated by using an existing powder form of adsorbent material, and may consequently enhance trapping efficiency, such as minimizing bleed emission, etc. Alternatively, it should be understood that the second trapping member 122 may be formed of various types of ceramic material, although the present disclosure mainly focuses upon the use of plastic material.

[0033]Referring to FIGS. 2 and 3, the canister 100 for a vehicle, whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com