Lean duplex stainless steel having superb drawing property and method for producing same

a duplex stainless steel and drawing property technology, applied in the field of lean duplex stainless steel having a superb drawing property, can solve the problems of reducing price competitiveness, increasing manufacturing costs, and reducing price competitiveness compared to other steel types, so as to improve workability, save resources, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

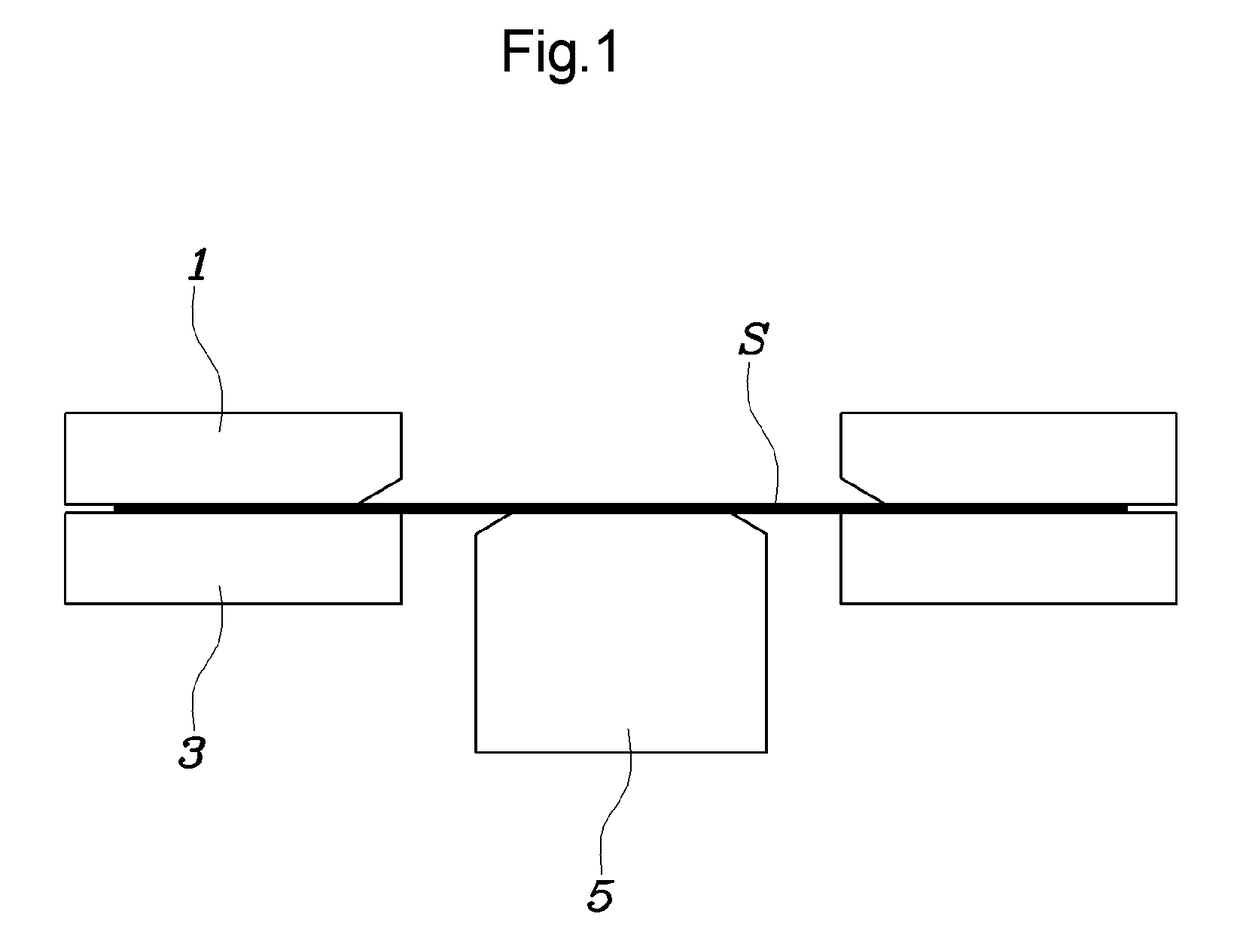

[0030]Hereinafter, embodiments and other matters needed for those skilled in the art to readily understand the contents of the present disclosure will be described in detail with reference to the accompanying drawings.

[0031]However, the present disclosure may be implemented in various different forms within the range described in the claims, and embodiments described below are only illustrative despite the expression.

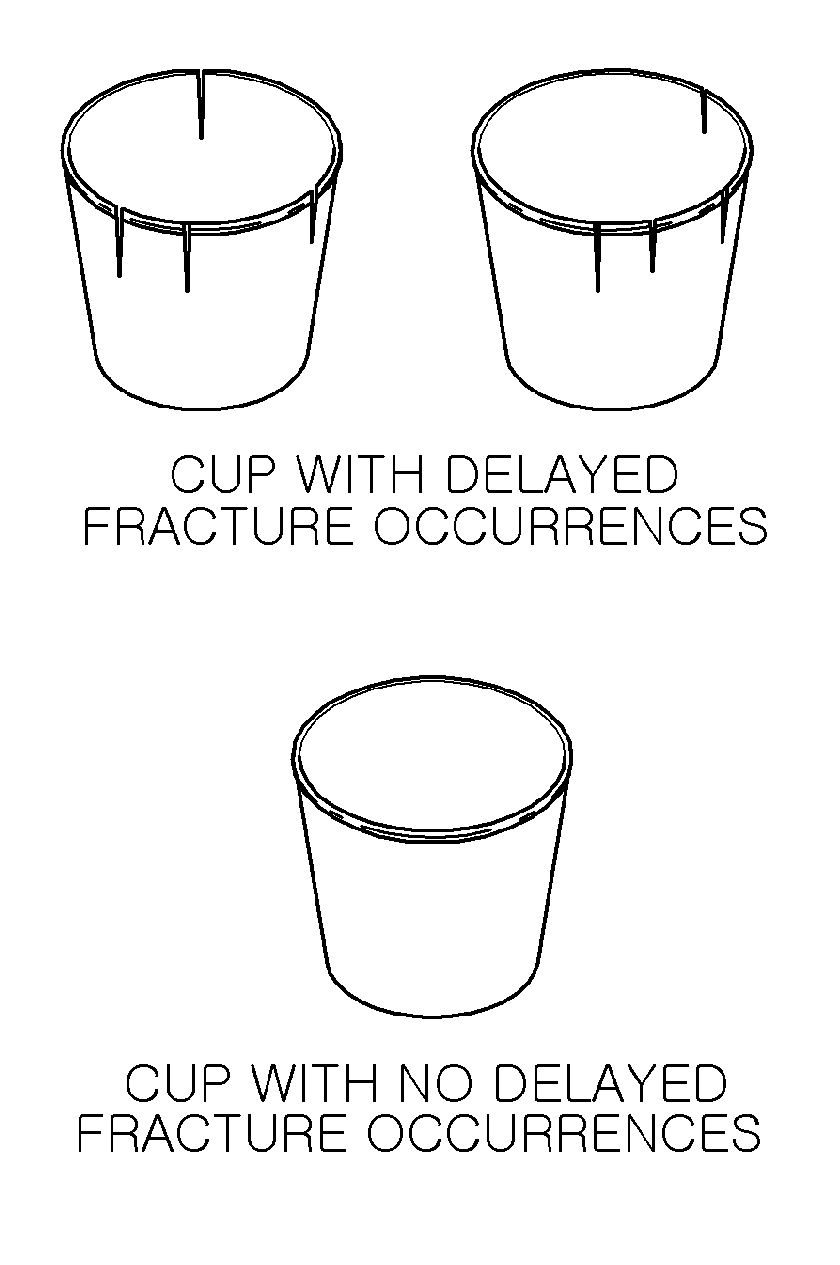

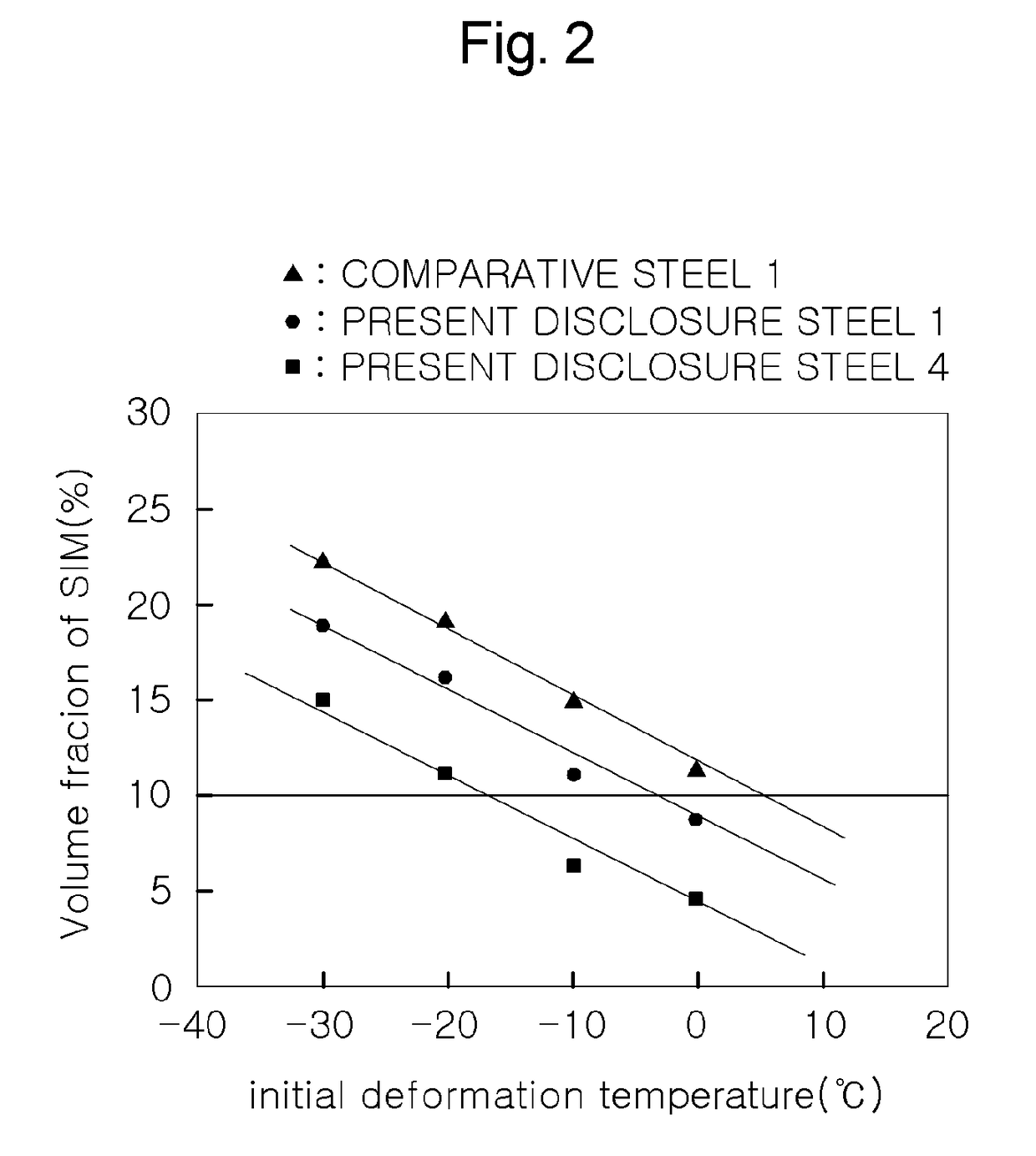

[0032]The present disclosure relates to, among duplex stainless steel having a dual-phase of austenite phase and ferrite phase, lean duplex stainless steel having a superb drawing property and lowering the content of high-priced alloy elements such as Ni, Mo, Si and Cu, and a method for producing the same.

[0033]Lean duplex stainless steel is capable of maintaining equal or higher acid resistance compared to 304 steel that is general austenitic stainless steel, and is also capable of securing equal or higher elongation compared to austenitic stainless steel, and therefor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| acid resistance | aaaaa | aaaaa |

| pitting corrosion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com