Suppressed upper receiver group having locking suppressor with through brake

a technology of suppressor and upper receiver, which is applied in the field of suppressor and suppressor with through brake, can solve the problems of difficult and time-consuming removal of residue buildup, and the suppression of the optimum operational characteristics, so as to reduce the discharge of propellant gas, prevent excessive back pressure, and reduce the effect of pressure conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

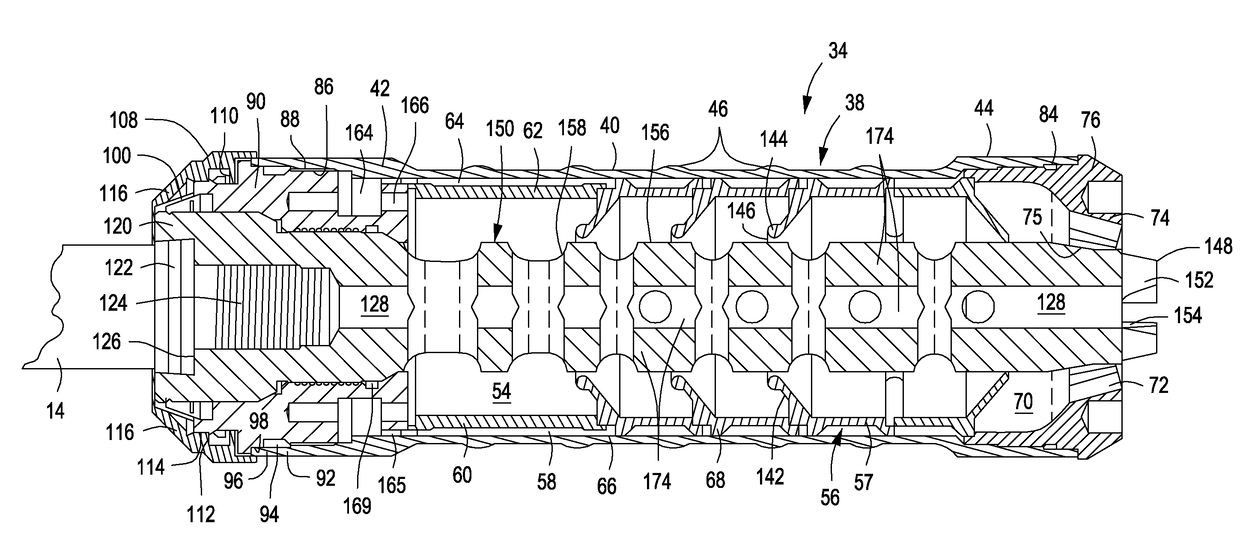

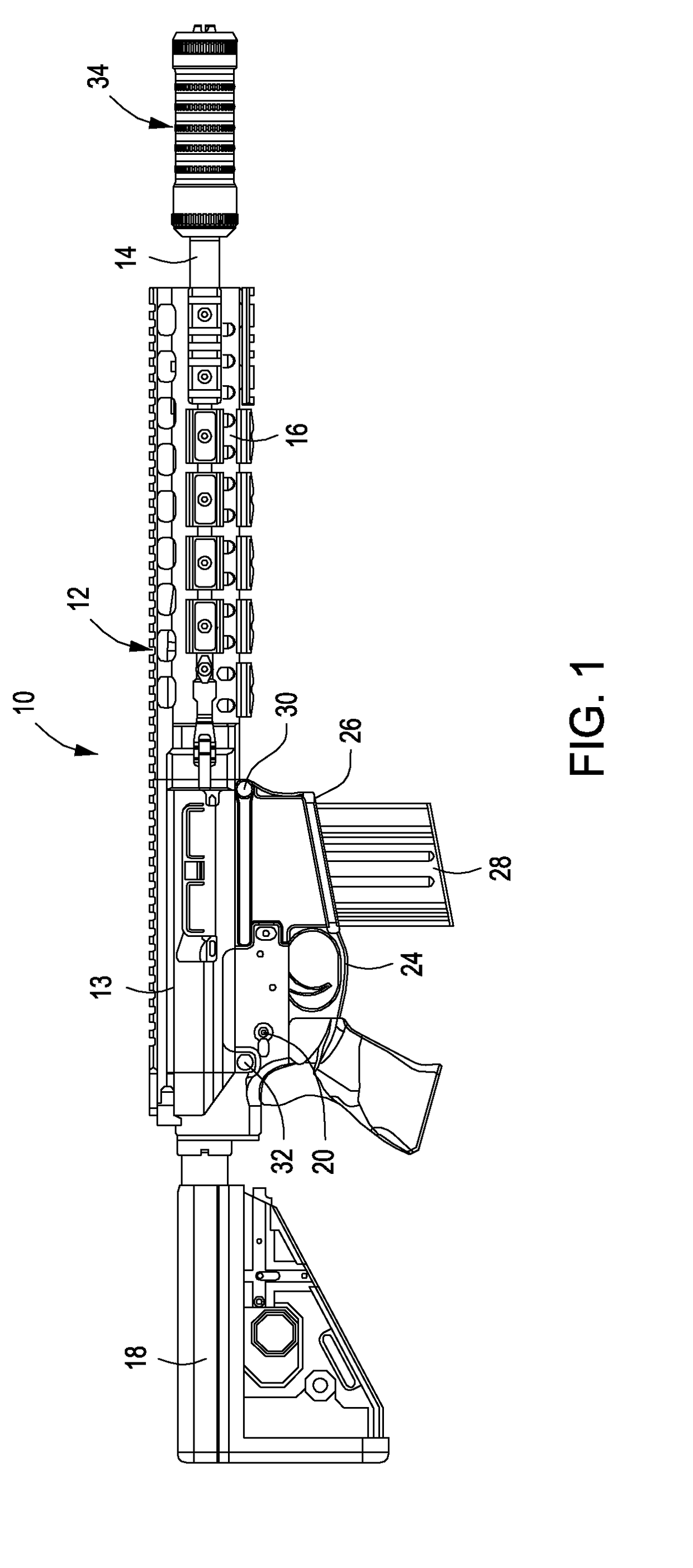

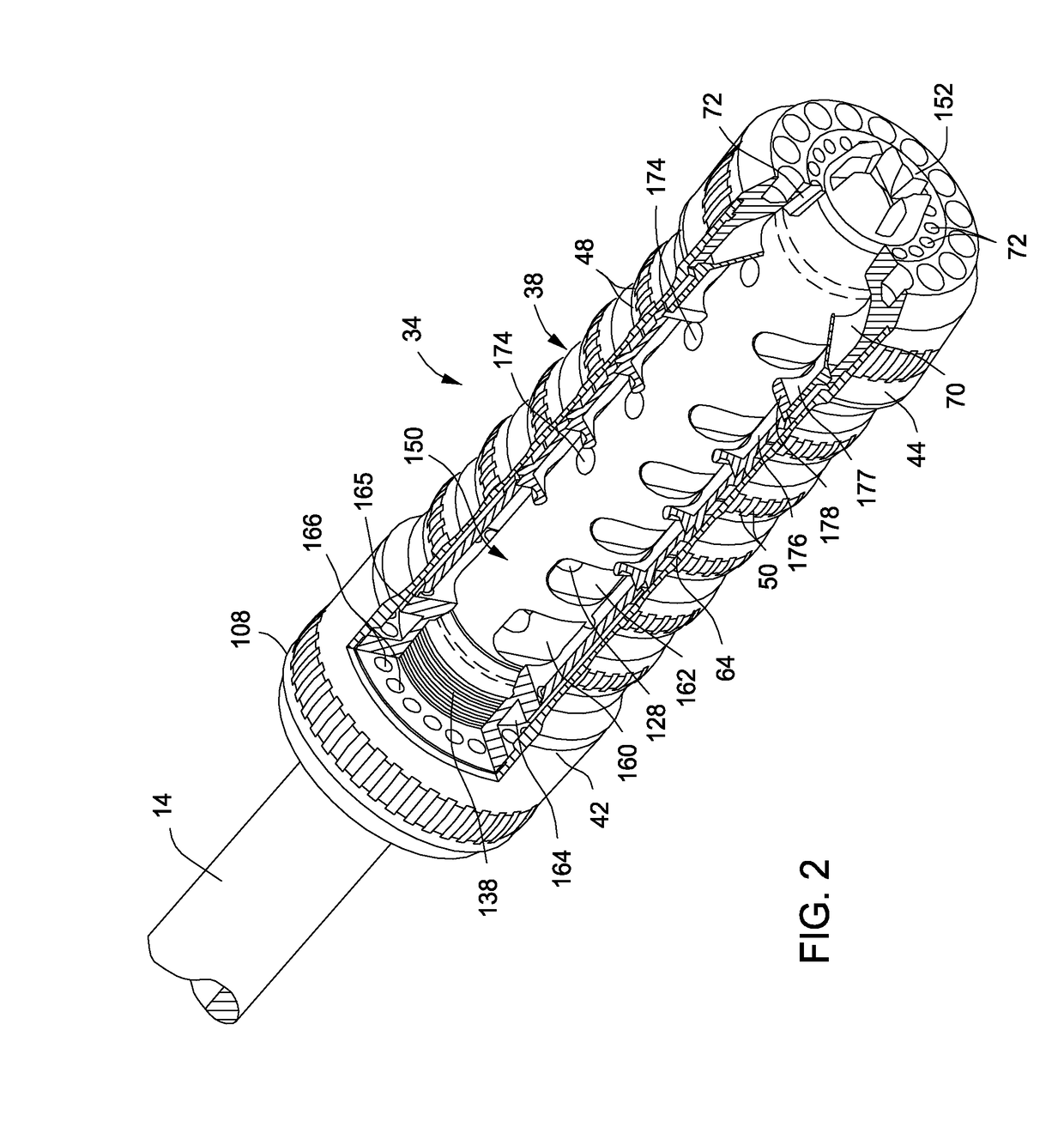

[0030]Referring now to the drawings and first to the side elevation view of FIG. 1, a tactical firearm constructed according to the principles of the present invention is shown generally at 10 and is of the character identified as an M-4, M-16 or AR-15 auto-loading rifle. The M-4 and M-16 rifles are typically utilized by military and law enforcement personnel and have settings for semi-automatic fire, where the trigger of the rifle is pulled for discharge of individual rounds of ammunition and full automatic fire, where the rifle will continuously fire round after round as long as the trigger remains pulled. AR-15 tactical rifles are typically provided with a non-adjustable setting that limits the rifle to semi-automatic fire. AR-15 rifles are widely used by sportsmen for target shooting, hunting and a wide range of general shooting activities.

[0031]The firearm 10 has a barrel cartridge or upper receiver group shown generally at 12 in FIG. 1 is generally defined by an upper receiver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com