Polytetrafluoroethylene textile and manufacturing method thereof

a polytetrafluoroethylene textile and manufacturing method technology, applied in the field of textiles, can solve the problems of poor durability, poor waterproof function, original permeability of the fabric, etc., and achieve the effects of improving the ability of waterproofing and moisture permeation of the polytetrafluoroethylene textile, facilitating knitting, and high durability and permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]For purposes of understanding the technical features, contents, advantages and technical effects achieved thereby, various embodiments of the present invention will now be described in more detail with reference to the accompanying drawings. Drawings are used for illustrating and assisting in understanding the detailed description, not represent the real scale and precise configuration of the present invention. Therefore, the claims cope of the subject matter are not interpreted or limited by the scale and configuration of the accompanying drawings. Further, for purposes of explanation, in the drawings, similar symbols typically identify similar components, unless context dictates otherwise.

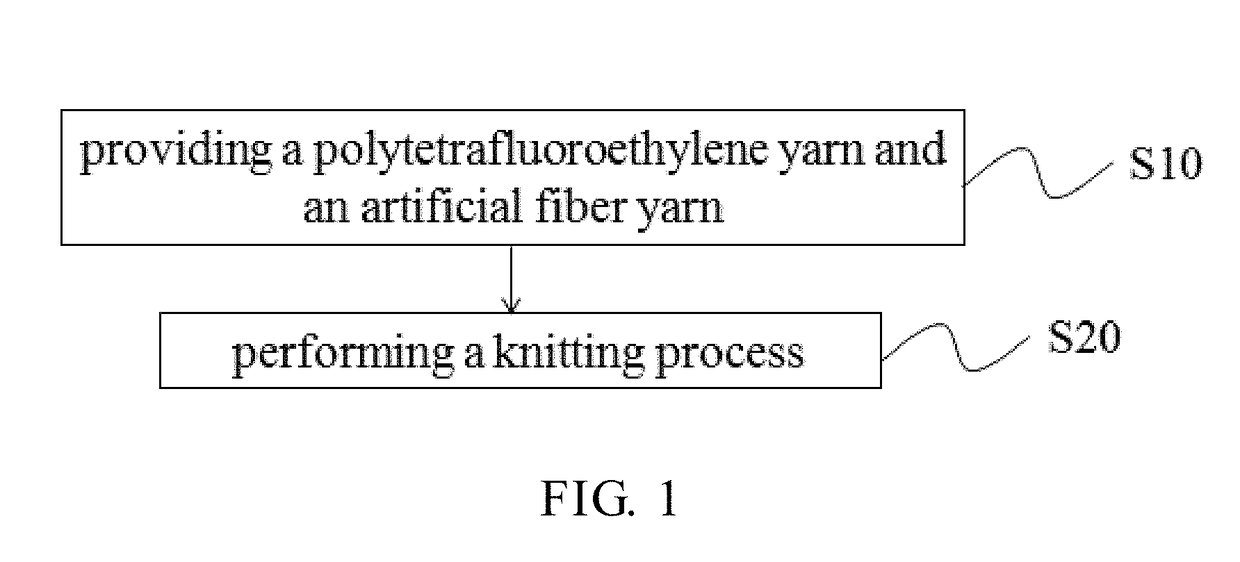

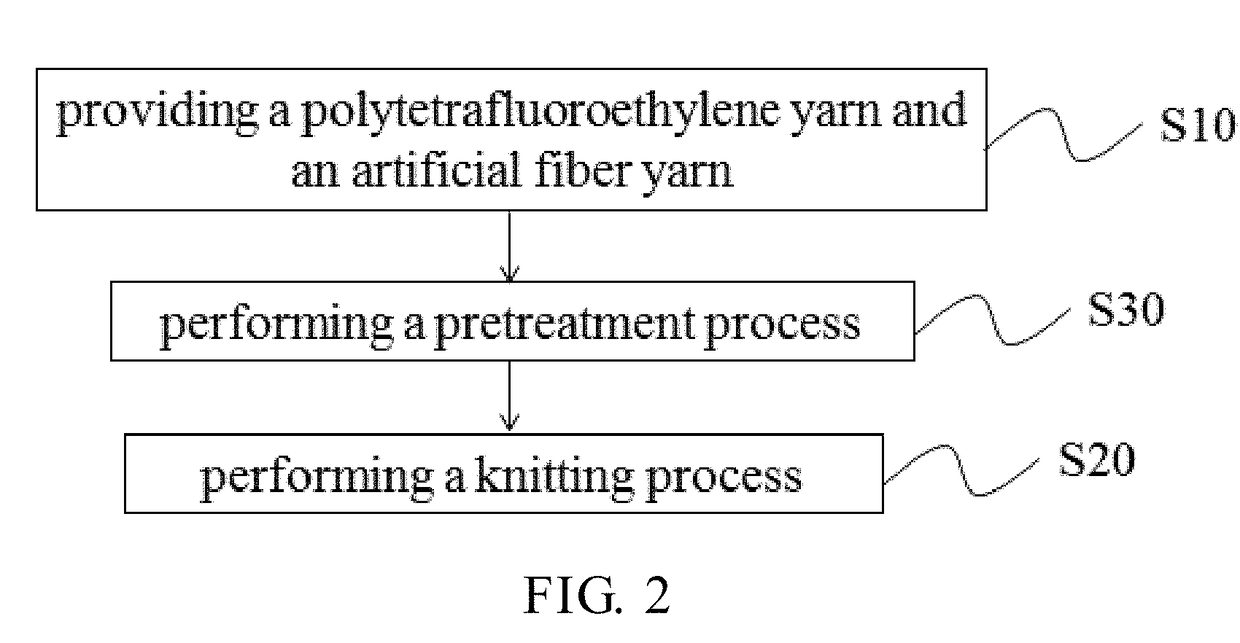

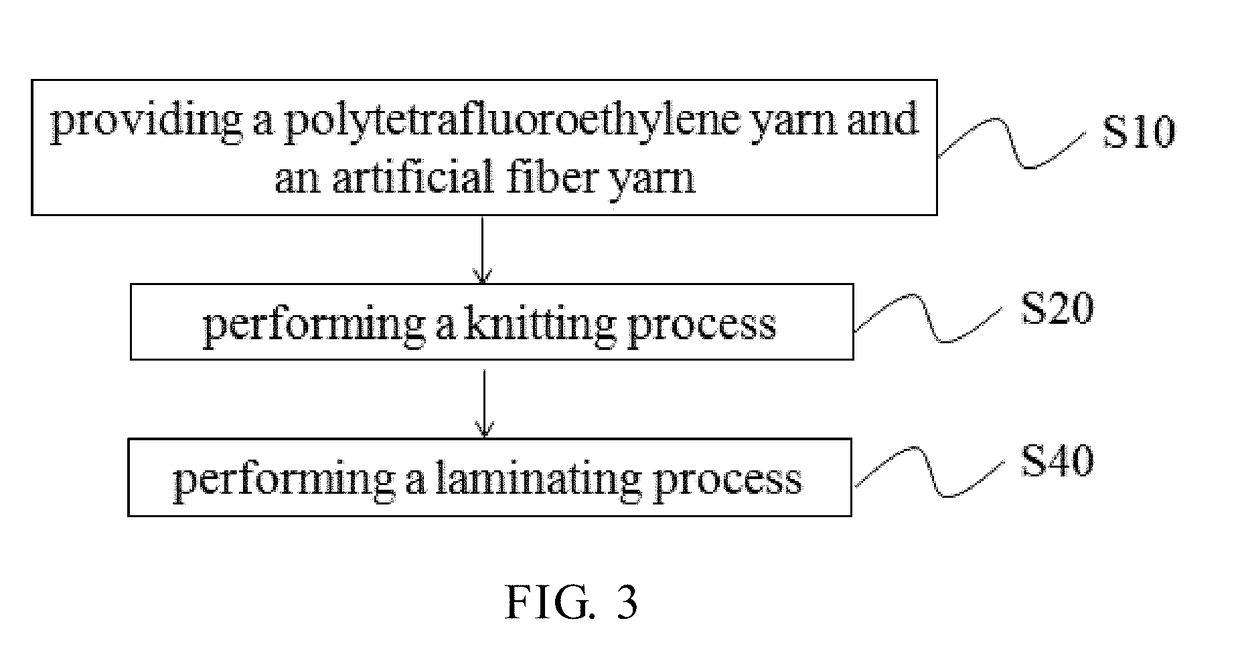

[0029]Referring to FIG. 1, FIG. 1 is a schematic flow diagram of the first preferred embodiment of the method of manufacturing the polytetrafluoroethylene textile of the present invention. As shown in FIG. 1, the method of manufacturing a polytetrafluoroethylene textile of the present inven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydrostatic pressure | aaaaa | aaaaa |

| water repellent | aaaaa | aaaaa |

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com