Circuit board and battery connection module

a battery connection module and printed circuit board technology, applied in the field of printed circuit boards, to achieve the effect of saving the cost of circuit board replacement, reducing the area occupied by the fuse unit, and simple operation procedure at the time of repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]Before the present disclosure is described in detail, it should be noted that like elements are indicated by the same reference numerals in the following description.

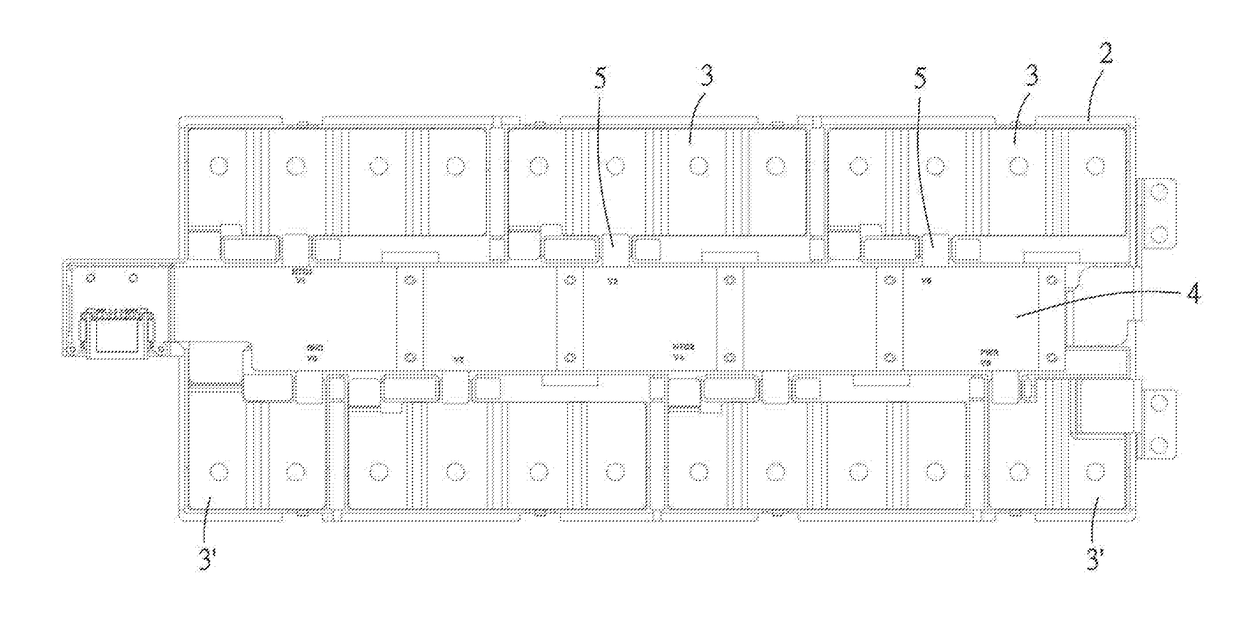

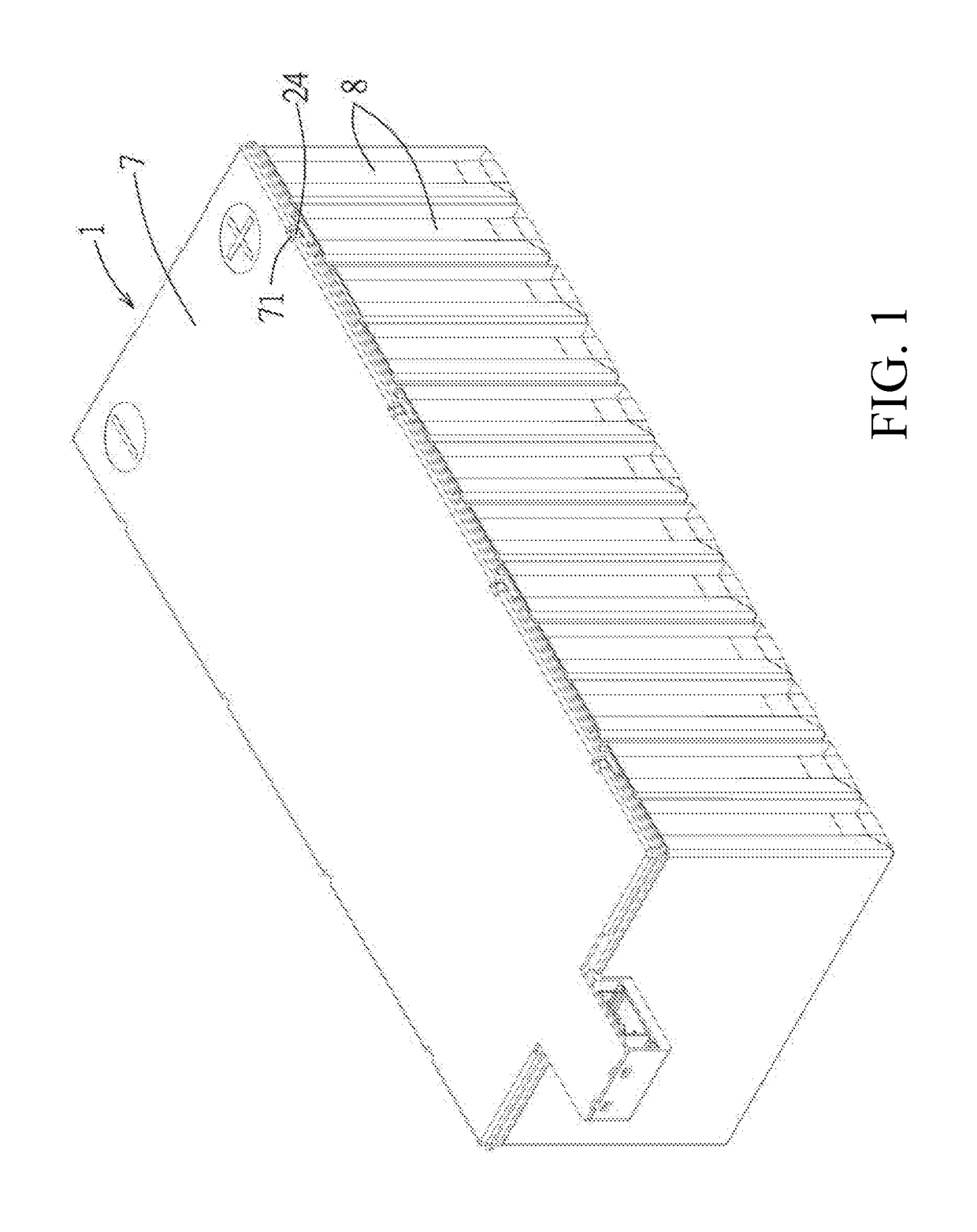

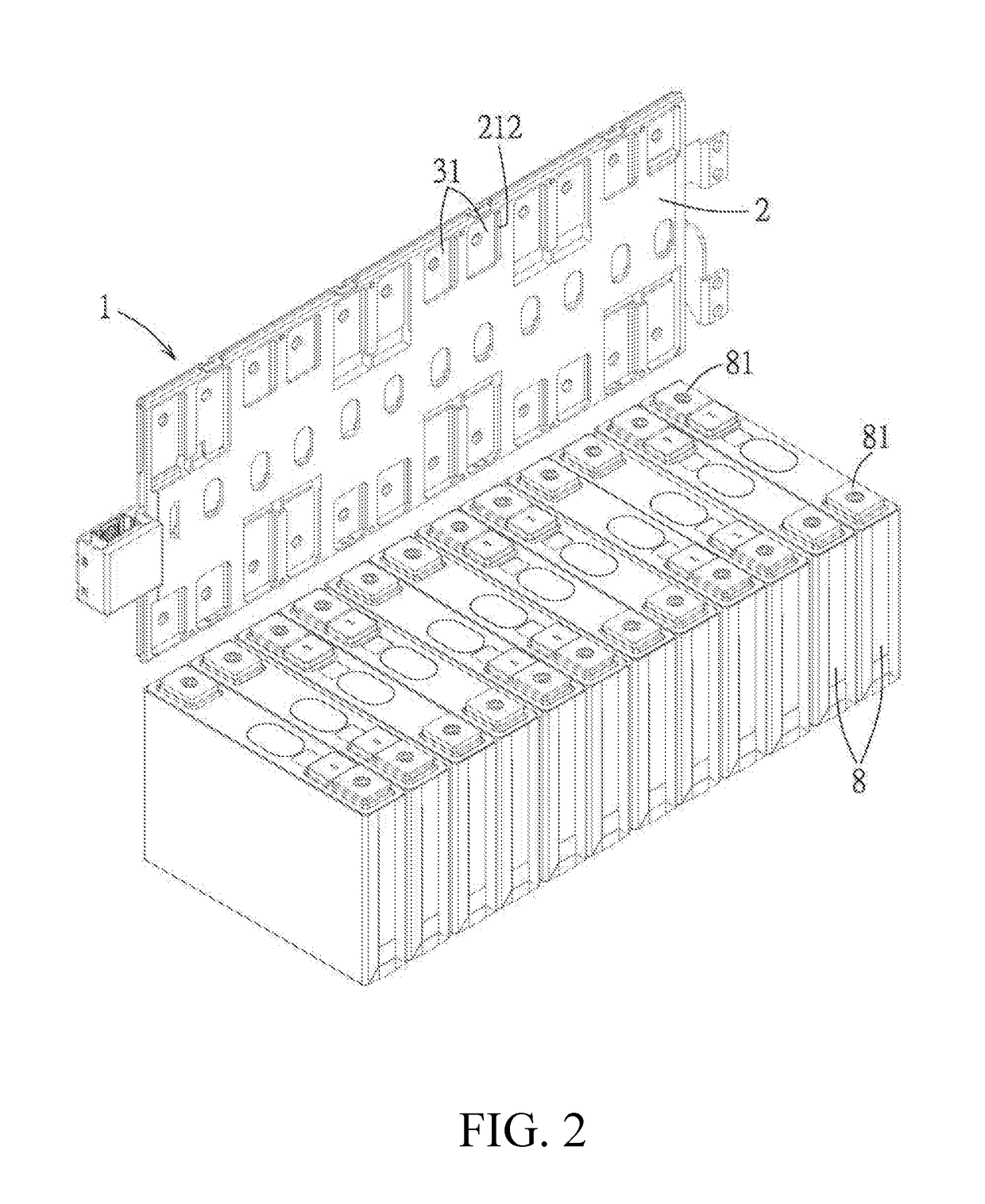

[0043]Referring to FIG. 1 and FIG. 2, an embodiment of a battery connection module 1 in the present disclosure is used to connect a plurality of batteries 8 arranged side by side.

[0044]Referring to FIG. 2 to FIG. 5, the battery connection module 1 comprises an insulating frame 2, a plurality of busbars 3, a circuit board 4, a plurality of conductive connecting tabs 5, a plurality of auxiliary connecting tabs 5′, an extension connecting tab 6 and a cover 7.

[0045]The insulating frame 2 is used to be provided on the plurality of batteries 8 and has a body 21, the body 21 is formed with a plurality of accommodating grooves 211 correspondingly accommodating the plurality of busbars 3 and limiting the plurality of busbars 3 in position, and a plurality of hollow portions 212 are formed in each accommodating groove 211. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current conductive | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| flexible | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com