Engine control device

a control device and engine technology, applied in the direction of electric control, ignition automatic control, engine starters, etc., can solve the problems of prolonging the time of the spark discharge caused by the ignition plug, aggravating emissions, and reducing the service life of the engine, so as to reduce the risk of ignition coil premature degradation, prolong the service life, and reduce the effect of fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

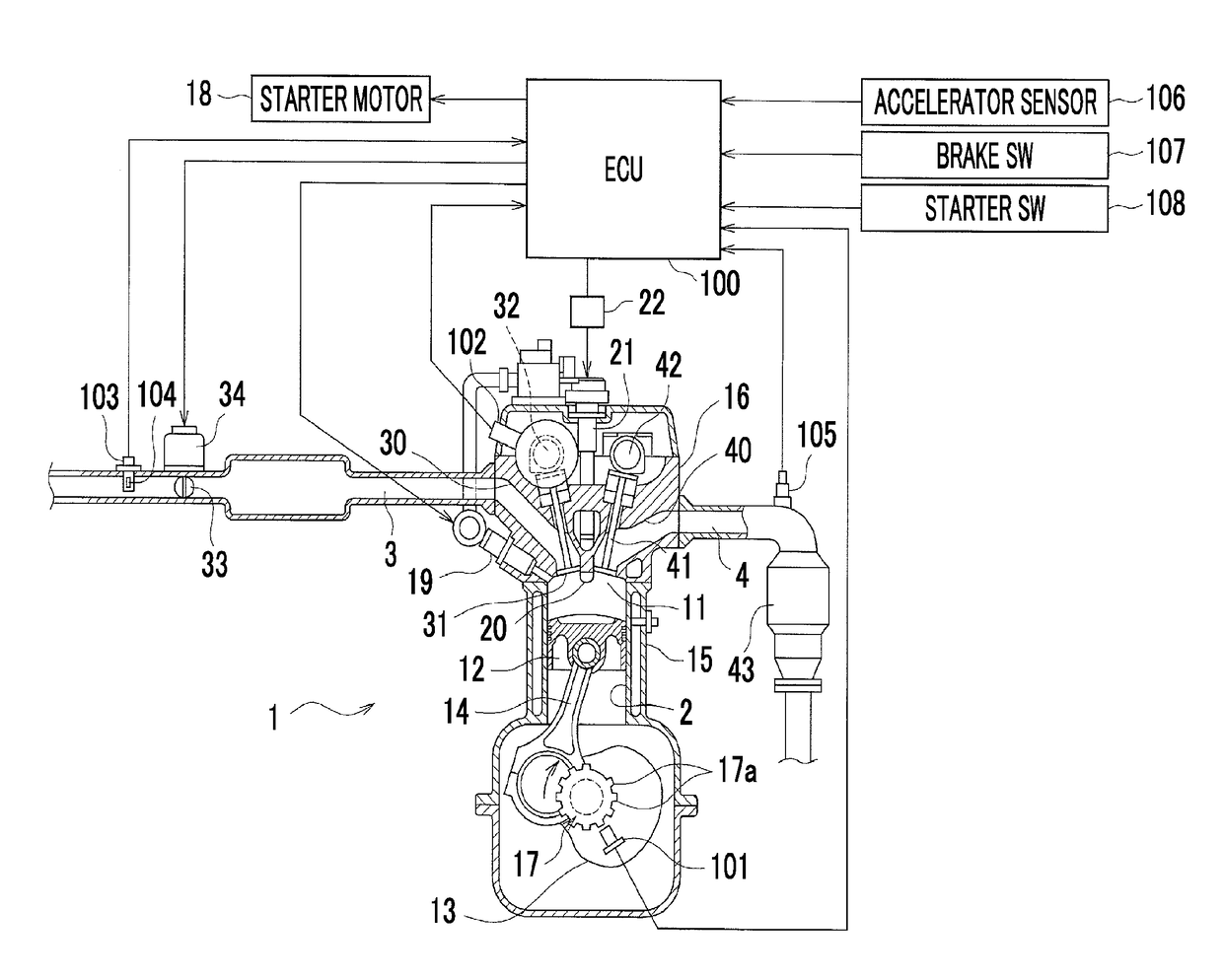

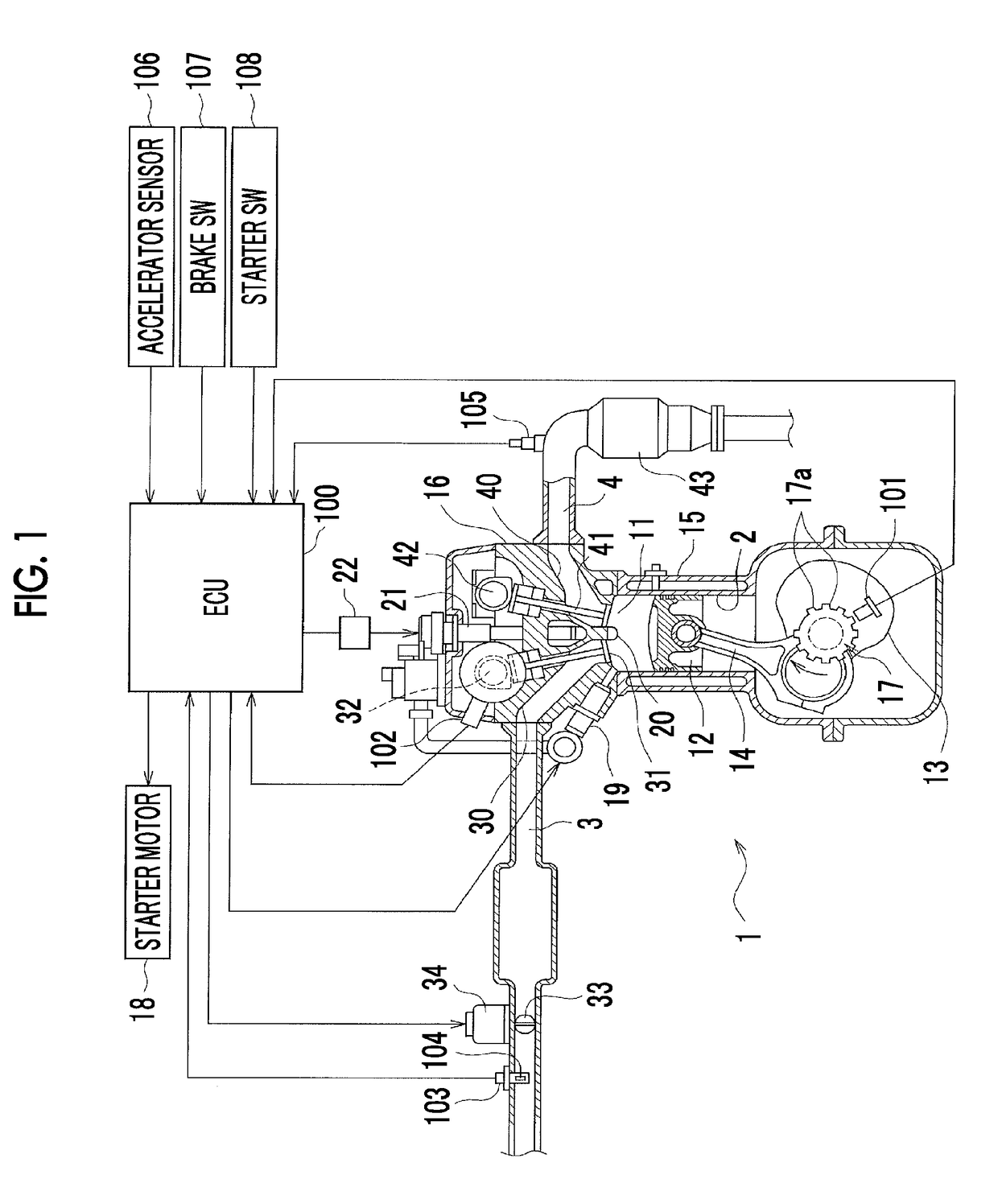

Method used

Image

Examples

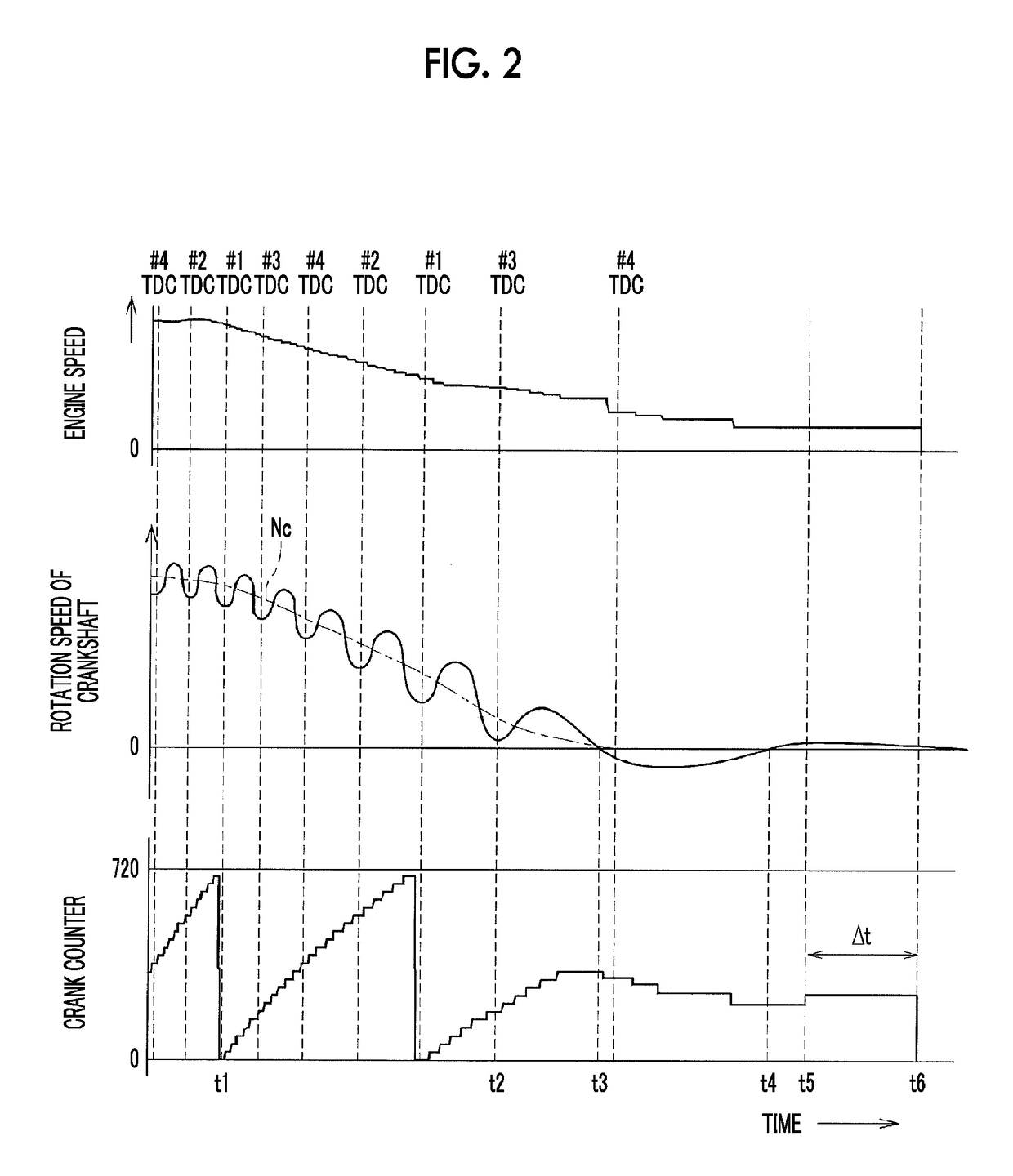

modification example 1

[0087]Modification Example 1 in which a timing for starting the energization (energization start timing) to the ignition coil 21 is retarded in accordance with a decrease in the crank rotation speed Nc at an automatic stop of the engine 1 will be described with reference to FIGS. 6 and 7. Also in Modification Example 1, the configuration of the control system of the engine 1, the procedure of the stop and start control, and the like are the same as those of the above-described embodiment, and different portions will be described below.

[0088]A routine of the automatic stop processing related to Modification Example 1 is illustrated in FIG. 6, and first, the same processing as Steps ST201 to ST203 of the flow of FIG. 4 is performed in Steps ST301 to ST303 after a start. When a negative determination (NO) that the crank rotation speed Nc is higher than the threshold value Nc1 is made in Step ST303, the process proceeds to Step ST304, the spark discharge caused by the ignition plug that...

modification example 2

[0095]Modification Example 2 in which the energization to the ignition coil 21 is cut off in accordance with the reverse operation of the crankshaft 13 without changing the spark discharge caused by the ignition plug according to a decrease in the crank rotation speed Nc like the above embodiment and Modification Example 1 will be described with reference to FIGS. 8 and 9. Also in Modification Example 2, the configuration of the control system of the engine 1, the procedure of the stop and start control, and the like are the same as those of the above embodiment, and different portions will be described below.

[0096]The routine of the automatic stop processing related to the modification example 2 is illustrated in FIG. 8. First, in Step ST401 after start, a fuel cut is performed similar to Step ST201 of the flow of FIG. 4, and in Step ST402, processing of the spark discharge caused by the ignition plug is performed similar to Step ST204. Accordingly, when the rotation speed of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com