System and method for air conditioner evaporator coil cleaning

a technology of air conditioner and evaporator coil, which is applied in the direction of flush cleaning, cleaning using liquids, heating types, etc., can solve the problems of air conditioner operating at reduced efficiency, other repairs to be necessary, and air conditioner motor strain, so as to reduce the cost of repairs and operate more efficiently, prevent costly repairs, and reduce the effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

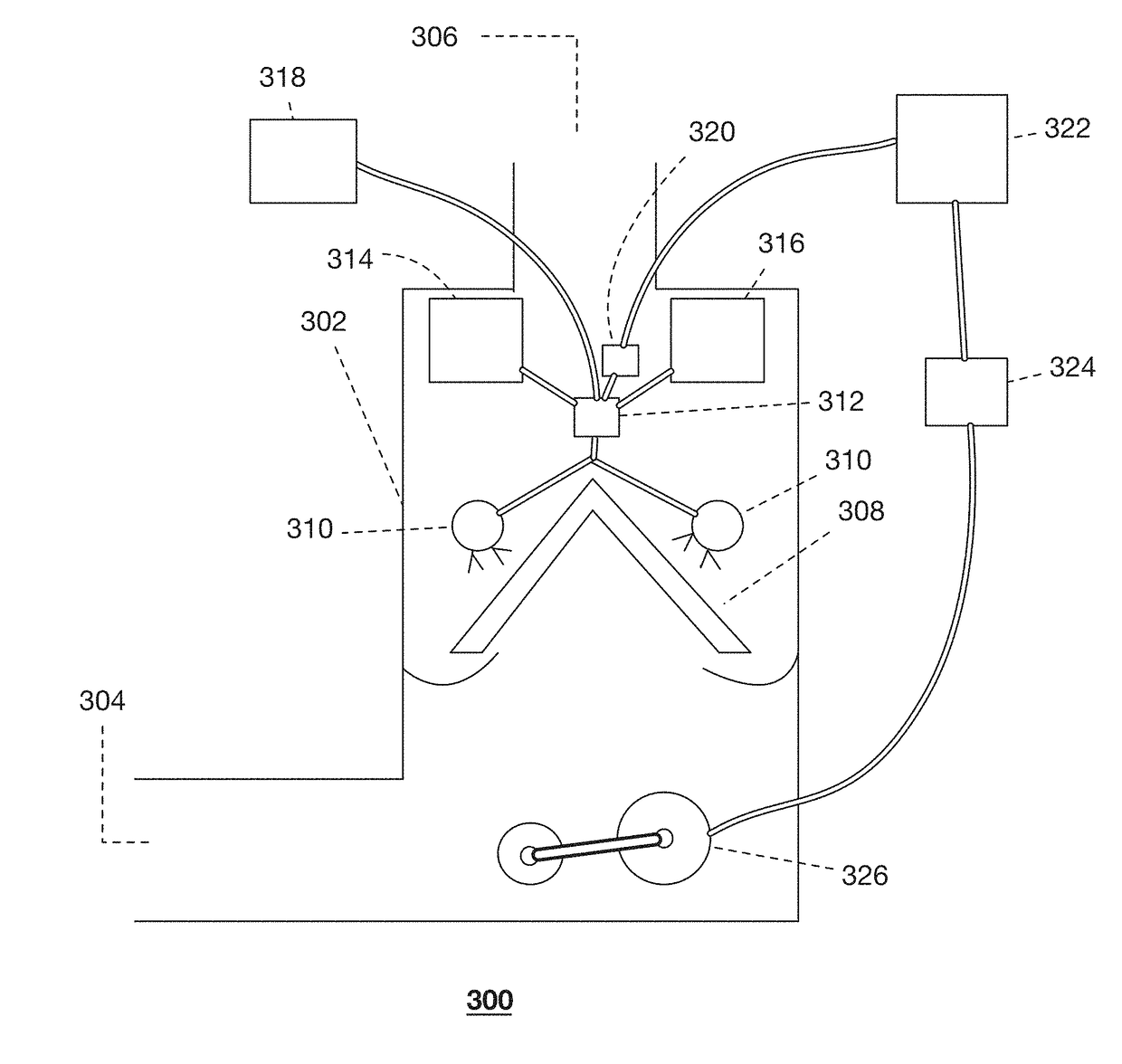

[0018]The evaporator coil cleaning system is integrated into a machine, such as an air conditioning system, so that it can run on a schedule without human intervention. At certain intervals, the cleaning system powers down the machine, squirts cleaning solution onto the component(s) to be cleaned, waits a period of time for the cleaning solution to work, and then powers up the machine, allowing normal operations to resume.

[0019]As a preliminary matter, it will readily be understood by one having ordinary skill in the relevant art that the present disclosure has broad utility and application. As should be understood, any embodiment may incorporate only one or a plurality of the above-disclosed aspects of the disclosure and may further incorporate only one or a plurality of the above-disclosed features. Furthermore, any embodiment discussed and identified as being “preferred” is considered to be part of a best mode contemplated for carrying out the embodiments of the present disclosur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com