Refrigeration cycle device and heat cycle system

a technology of refrigerating cycle and heat cycle system, which is applied in the direction of mechanical equipment, refrigeration components, light and heating equipment, etc., can solve problems such as deterioration of use components, and achieve the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021]Embodiment for carrying out the present invention are described below with reference to the drawings.

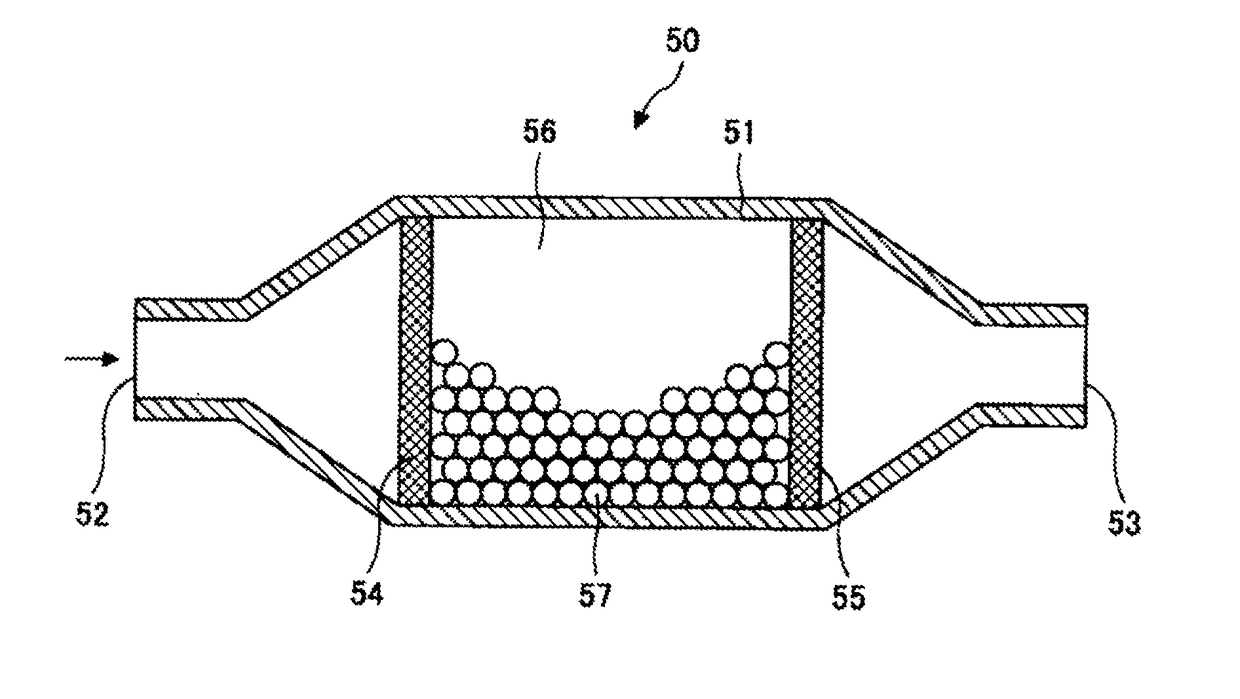

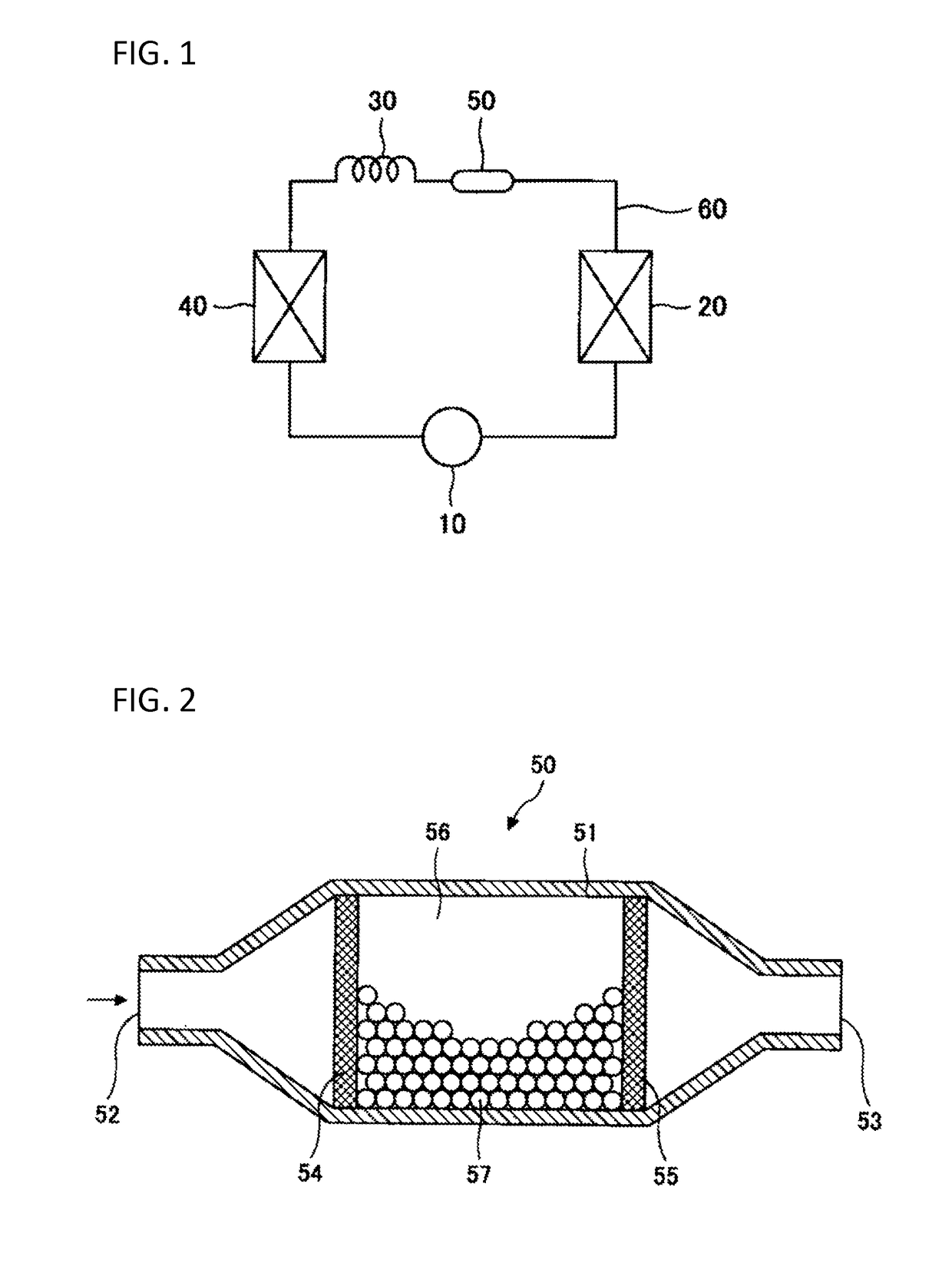

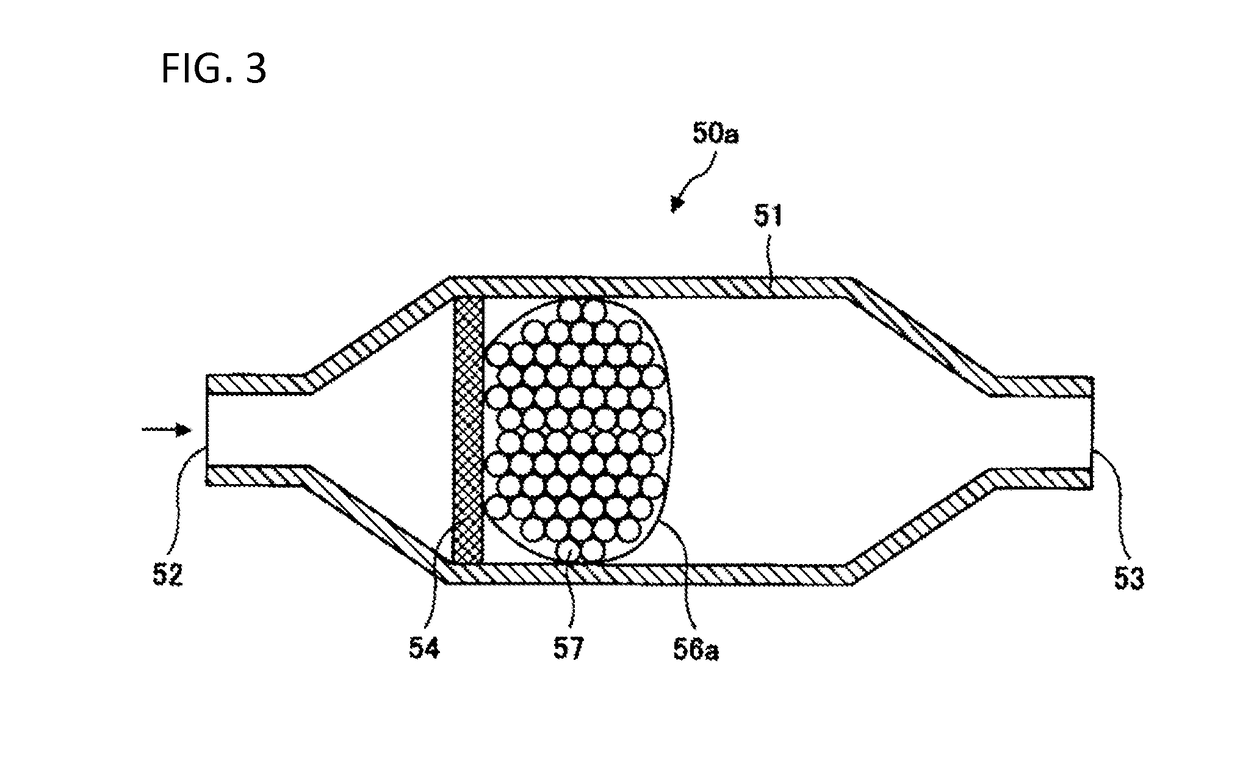

[0022]FIG. 1 is an overall configuration diagram illustrating an example of a refrigeration cycle apparatus in the embodiment of the present invention. As illustrated in FIG. 1, the refrigeration cycle apparatus in the embodiment includes a compressor 10, a condenser 20, a pressure reducing mechanism 30, an evaporator 40, a deoxidizing portion 50, and a pipeline 60. The compressor 10, the condenser 20, the pressure reducing mechanism 30, the evaporator 40 and the deoxidizing portion 50 are connected in an annular shape by the pipeline 60 so as to form a refrigeration cycle as a whole. In addition, in the refrigeration cycle apparatus in the embodiment, a working fluid containing an HFO is used as a working fluid. The details of the working fluid are described later. If water or oxygen is included within the refrigeration cycle, the HFO may be easily decomposed to generate sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com