Confocal Displacement Sensor

a sensor and confocal technology, applied in the field ofconfocal displacement sensors, can solve the problems of difficult to appropriately remove background components, deteriorate measurement accuracy, etc., and achieve the effects of reducing the influence of reflected light, reducing the influence of refractive index matching materials, and being easy to handl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]An embodiment of the present invention is explained below with reference to the drawings. In this specification, for convenience, a direction of an optical axis of a head unit is explained as an up-down direction. However, a posture and a direction during use of the head unit are not limited.

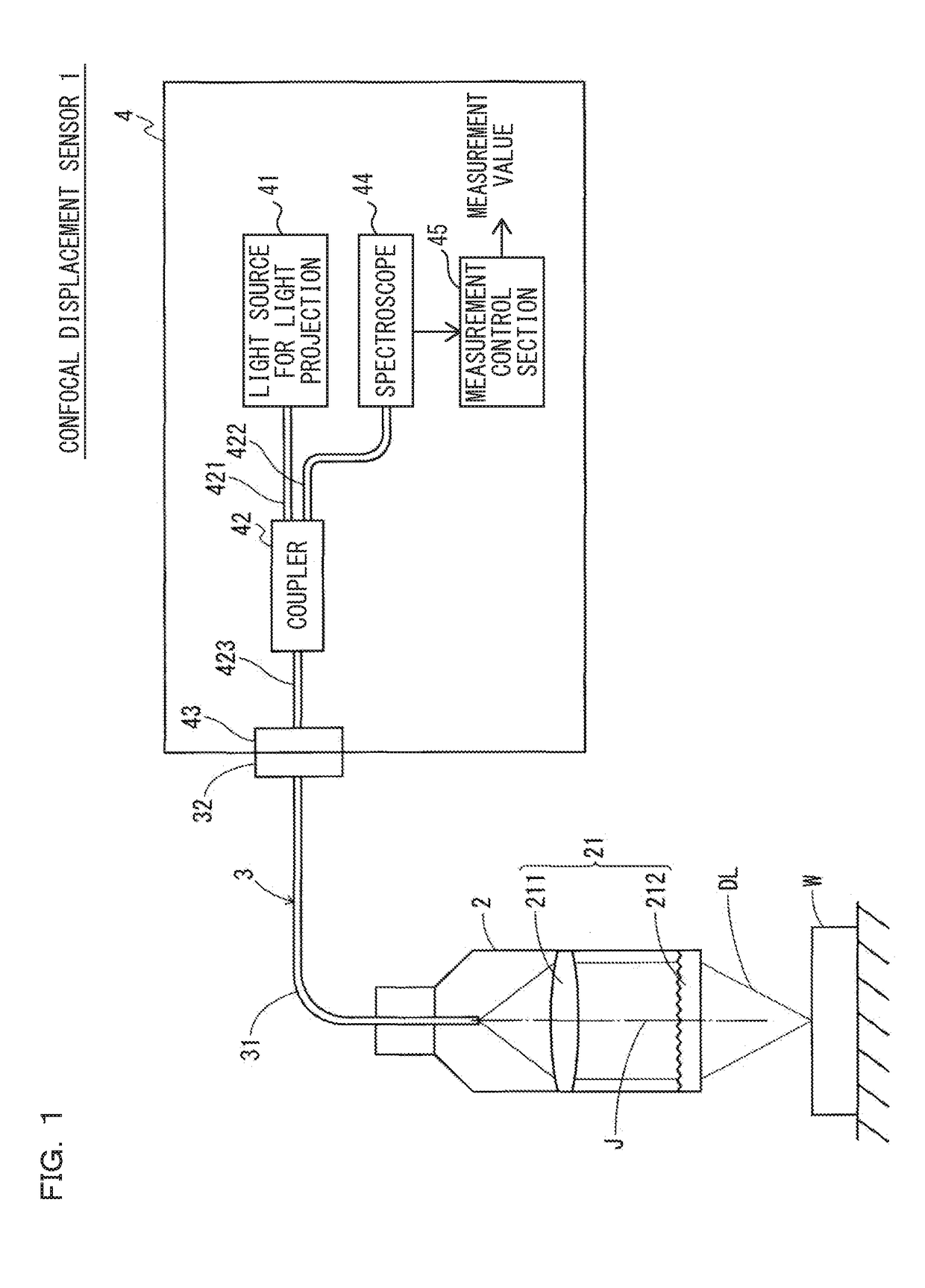

[0034]Confocal Displacement Sensor 1

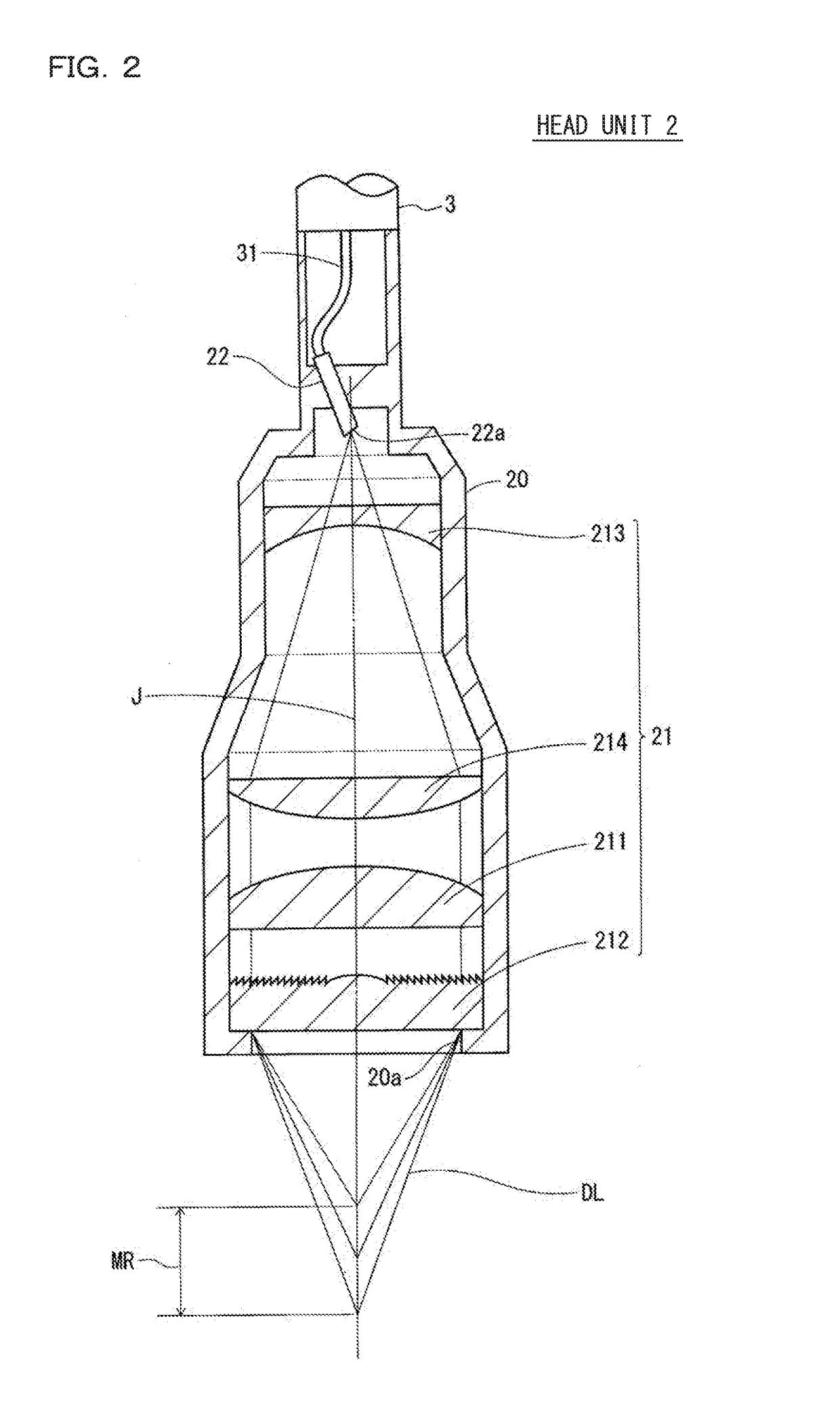

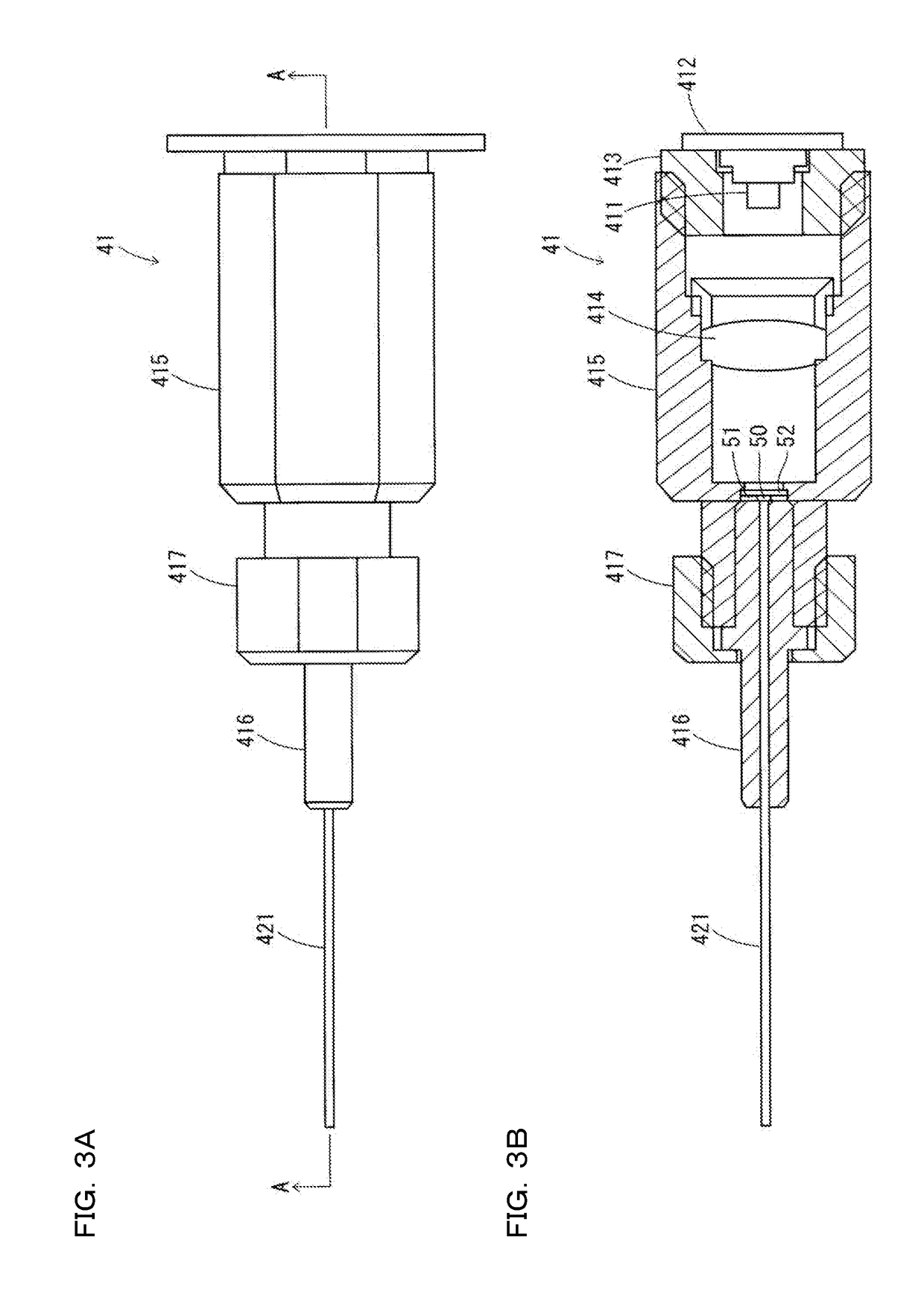

[0035]FIG. 1 is a system diagram showing a configuration example of a confocal displacement sensor 1 according to the embodiment of the present invention. The confocal displacement sensor 1 is an optical measurement device configured by a head unit 2, a fiber cable 3, and a control unit 4. The optical measurement device receives reflected light from a measurement object W when detection light DL is emitted from the head unit 2 and measures displacement of the measurement object W.

[0036]The head unit 2 and the control unit 4 are connected to each other via the fiber cable 3. The fiber cable 3 includes an optical fiber 31 that transmits light for light pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com