Process of Manufacturing Resilient, Fibrous, Piled Woven Fabric

a woven fabric and resilient technology, applied in the field of piled woven fabric manufacturing, can solve the problems of high manufacturing cost and bulkiness of the plurality of machines, inability to withstand the impact of a single machine, so as to achieve the effect of simplifying the process and combining the platform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

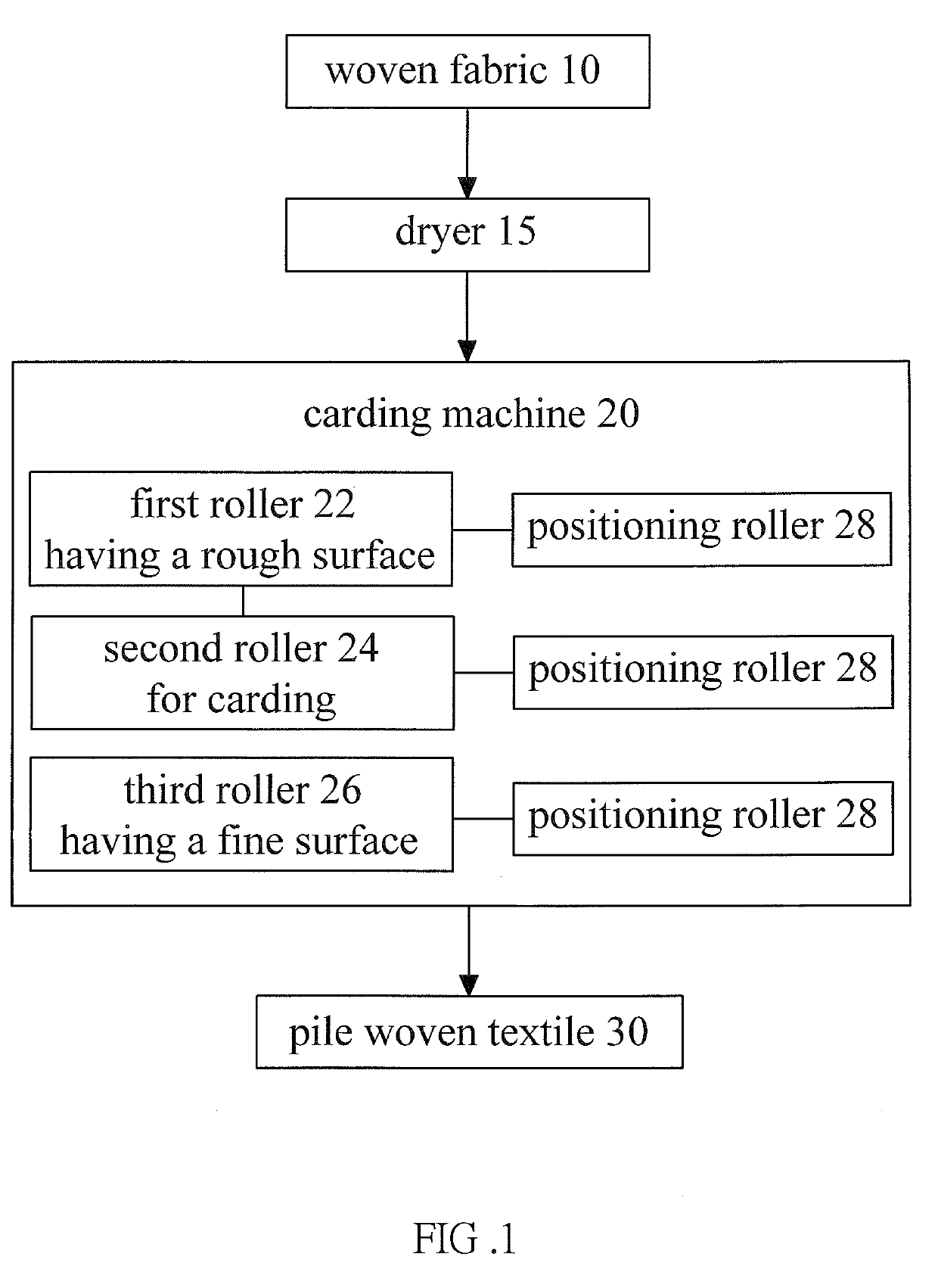

[0016]Referring to FIG. 1, a process of manufacturing resilient, fibrous, piled woven 30 fabric in accordance with the invention is illustrated. The process comprises the following steps:

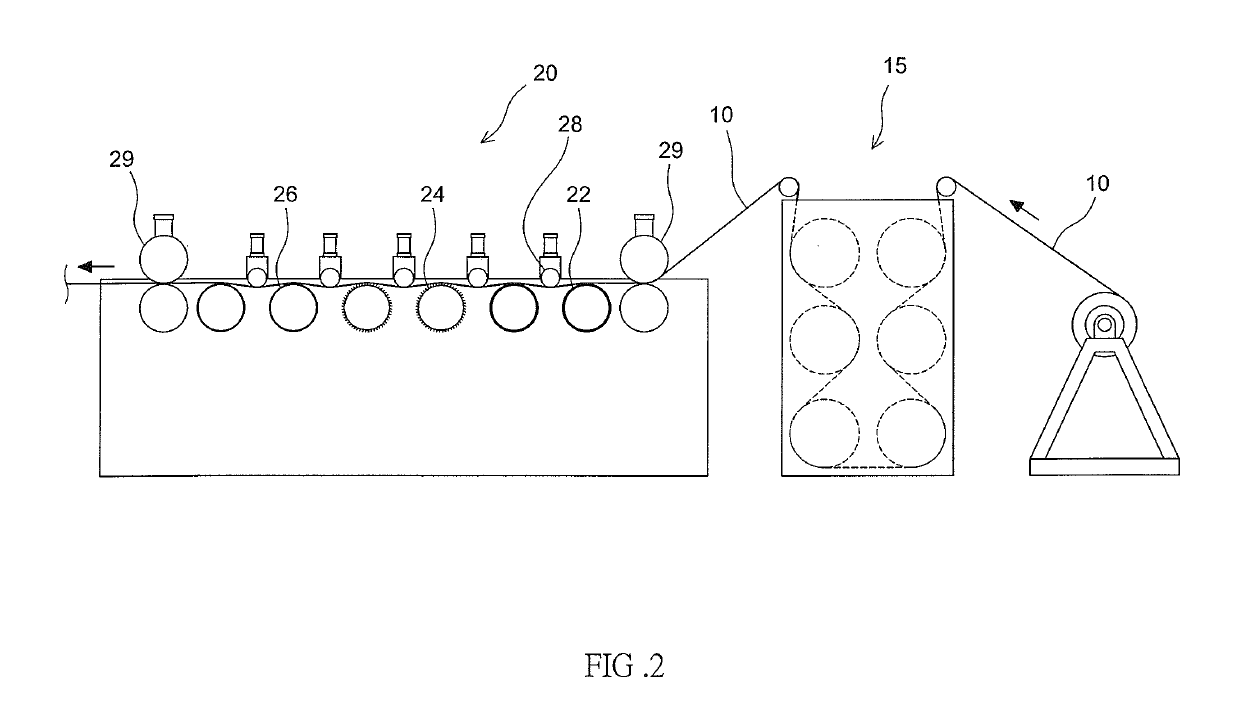

[0017]moving a resilient, fibrous woven fabric 10 through a dryer 15 to dry and comb out the resilient, fibrous woven fabric 10;

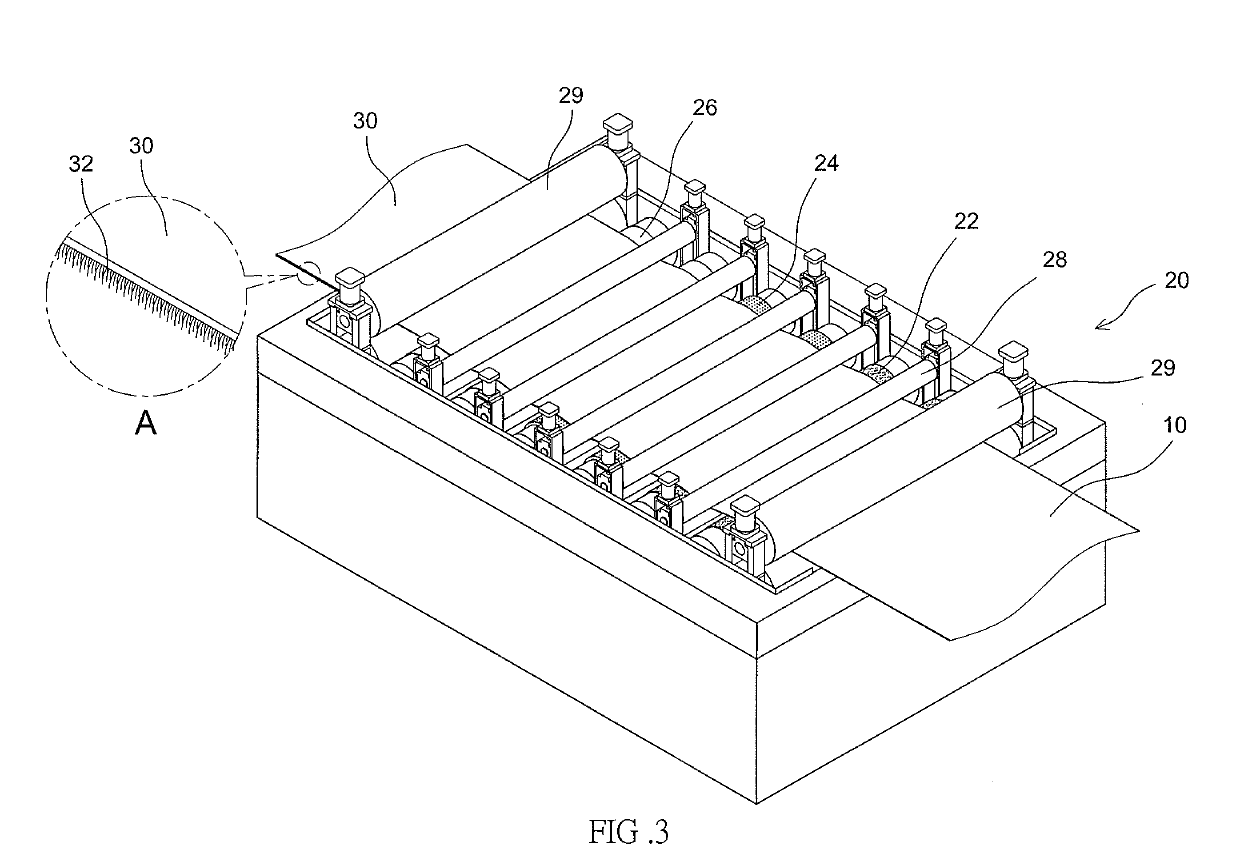

[0018]moving the resilient, fibrous woven fabric 10 through a platform type carding machine 20 in which one surface of the resilient, fibrous woven fabric 10 passes and contacts at least one first roller 22 having a rough surface, at least one second roller 24 for carding, and at least one third roller 26 having a fine surface so that the purposes of cutting fibers, combing out the pile, and smoothing the pile for greatly decreasing the probability of the resilient, fibrous woven fabric 10 having wrinkles when entering the platform type carding machine 20 can be obtained. Further, a plurality of positioning rollers 28 are provided above the first, second and third rollers 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilient | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

| adhesive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com