Aircraft brake cooling fan control system

a technology for controlling systems and air brakes, applied in the direction of aircraft braking arrangements, machines/engines, multi-dynamo-motor starters, etc., can solve problems such as adding mass to aircra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

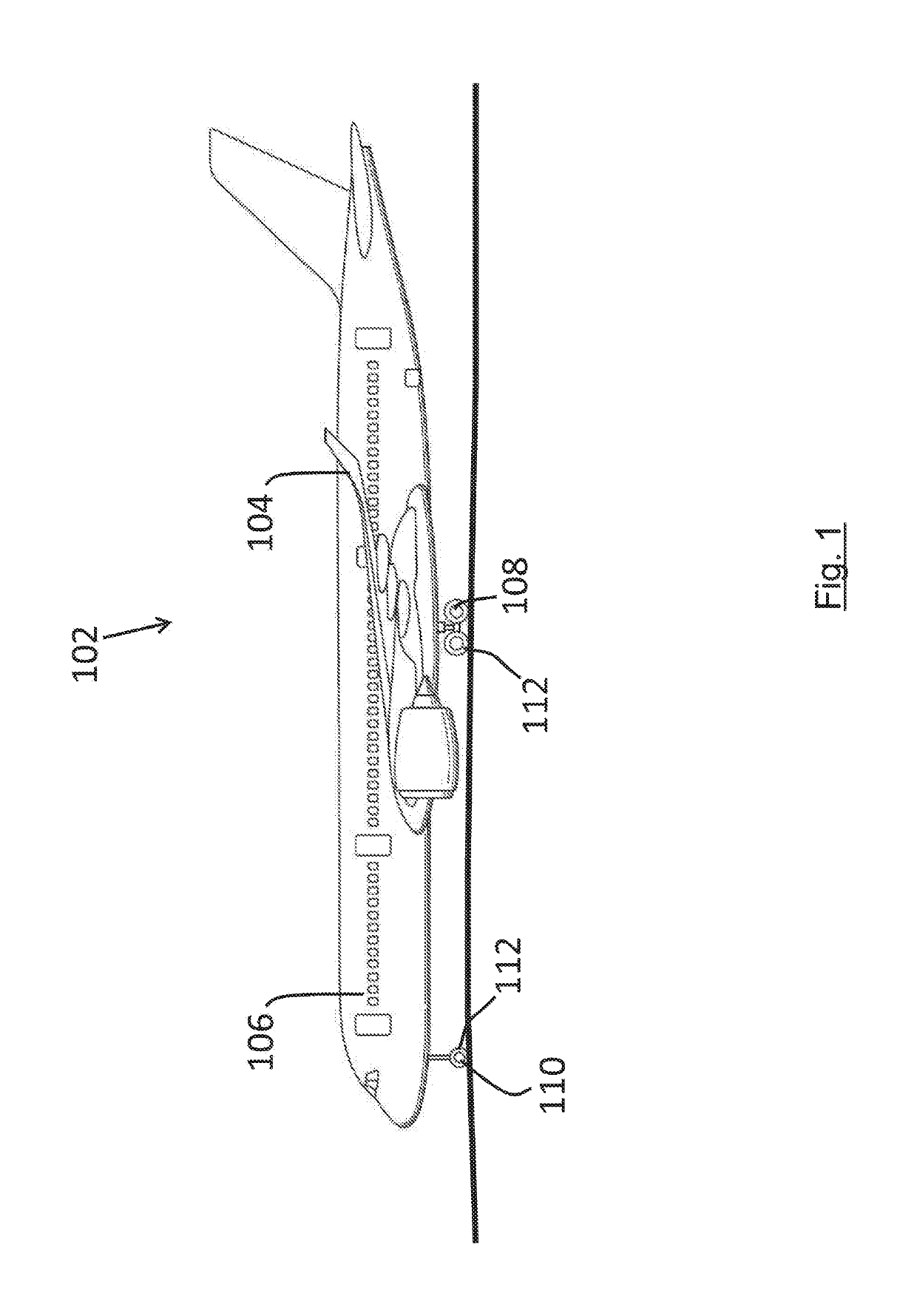

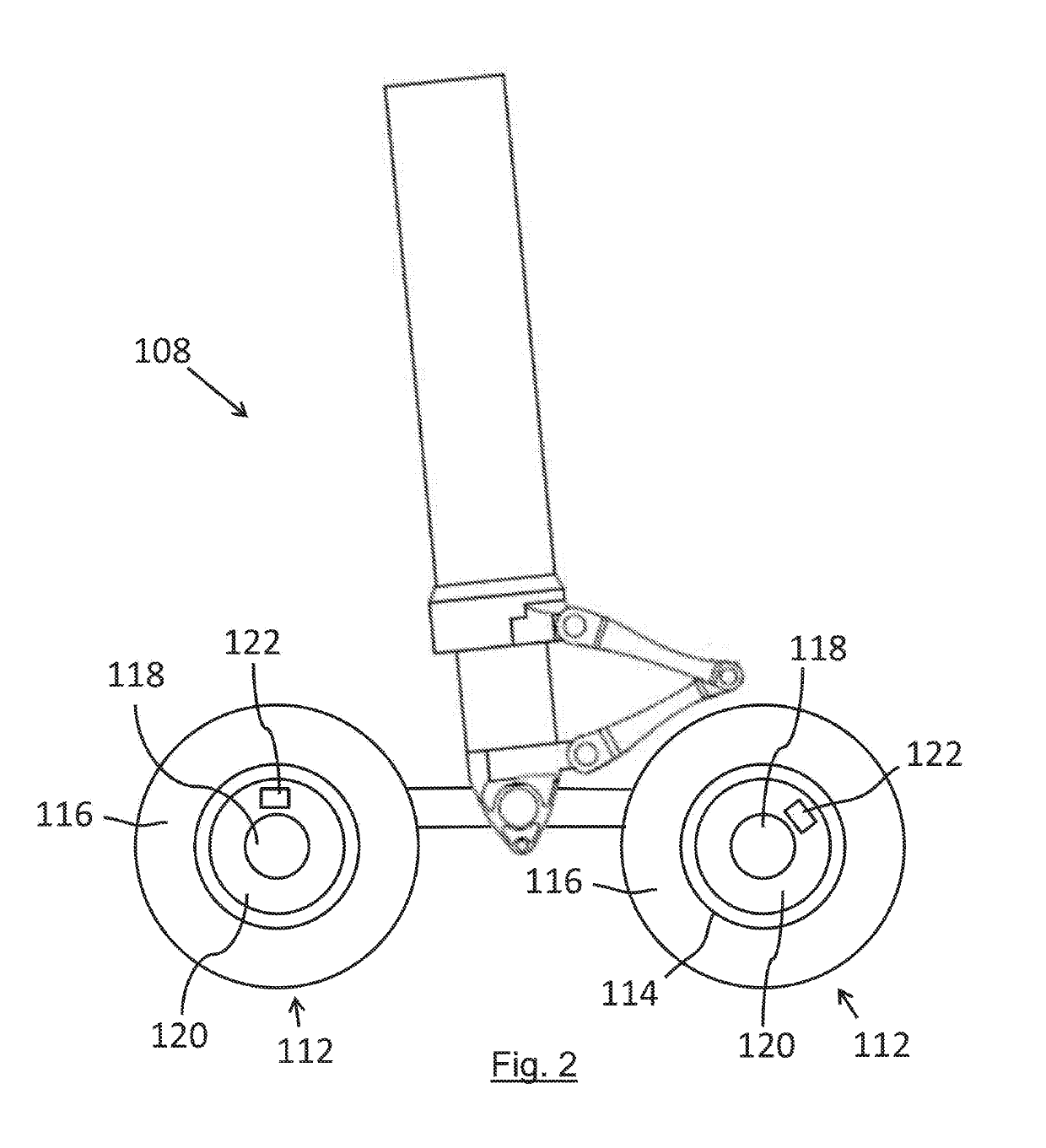

[0051]There now follows a description of specific embodiments, including the first and subsequent illustrated embodiments. FIG. 1 shows, in accordance with a first embodiment, an aircraft 2 on the ground 4. The aircraft has wheels 8 which are in contact with the ground and have associated brakes. In this case, the aircraft has just landed and the aircraft wheel brakes are hot. Before the aircraft takes-off again, the brakes are typically allowed to cool down. This cooling process is accelerated, when the aircraft is on the ground, by using brake cooling fans on the aircraft to cool the brakes by blowing air, from the surrounding environment (e.g. ambient air in the atmosphere), over the brakes and / or their associated structure. As shown schematically in FIG. 2, each fan (represented by box 10) includes an impeller 12 which is driven by an electric motor 14. The motor 14 is in the form of an induction motor powered by three-phase AC electrical power 16 and under the control of a brak...

second embodiment

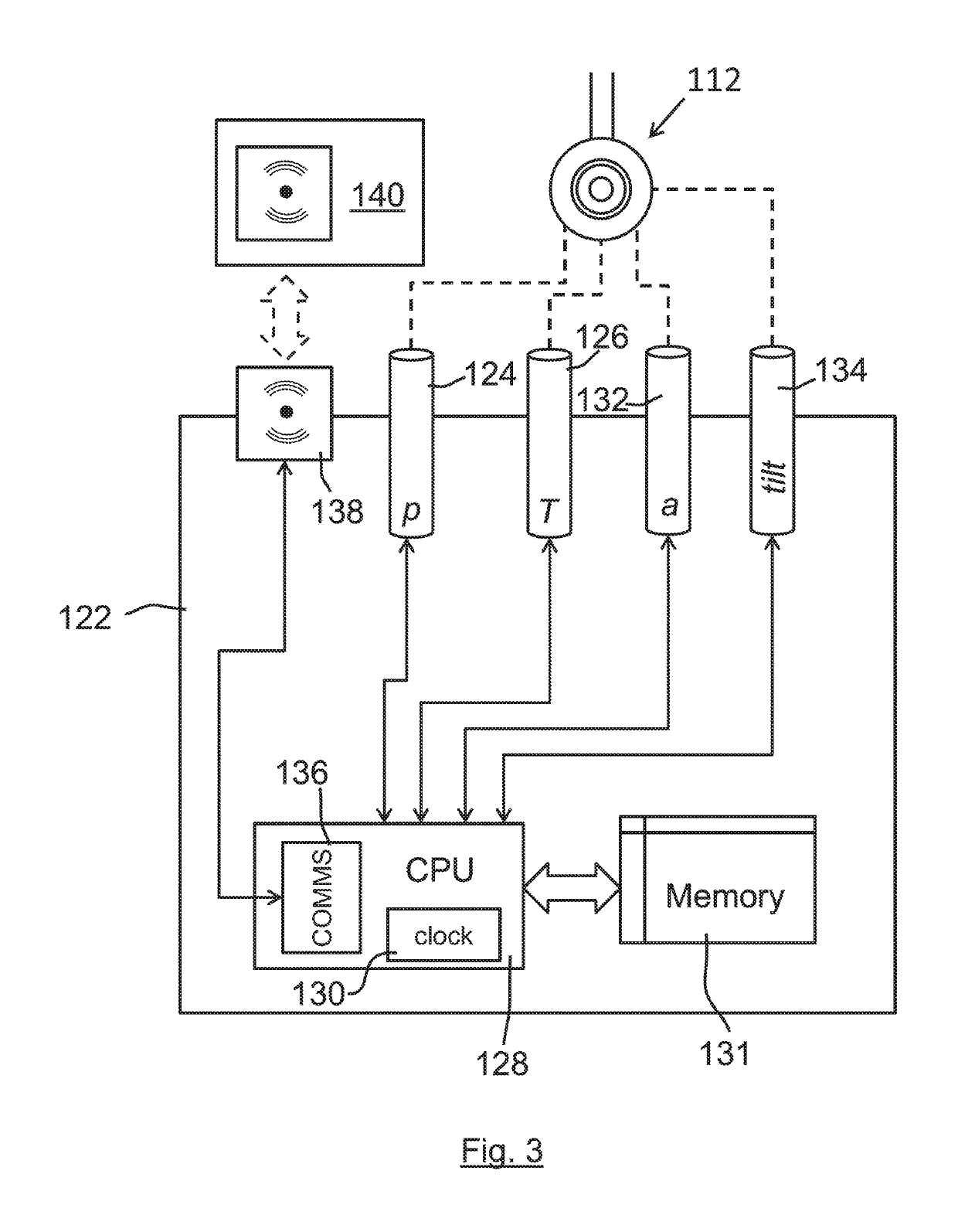

[0054]FIG. 3 shows a landing gear monitoring system 120 according to a In this embodiment, the fans 110 include AC induction motors located within the axles of the braked wheels 108, each driving an impeller housed within a shroud assembly (not shown). The impeller draws air in through the wheel and brake assembly 108, exiting through the debris guard (not shown) mounted on the outer face of the wheel assembly. This cools the brakes quicker than natural conduction and radiation. The control of each brake cooling fan 110 (comprising both motor and impeller) is provided by the landing gear monitoring system 120, which also controls / monitors other aspects of the operation of the landing gear. The landing gear monitoring system 120 controls the brake cooling fans 110 in response to pilot requests issued by means of operating a brake cooling fan switch 130 in the flight-deck. The state of the brake cooling fan switch is indicated by a lamp on the switch 130. A memo on an electronic flig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com