Monolithic Thermal Break Structural Member

a structural member and monolithic technology, applied in the field of fenestration assembly, can solve the problems of reducing the overall structural integrity of the fenestration assembly, reducing the thermal efficiency of all climates, and fenestration art, and achieves enhanced thermal and structural properties, and low thermal conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]In the following description, the present invention is set forth in the context of various alternative embodiments and implementations involving a monolithic thermal break structural member and its use in fenestration products. While the following description discloses numerous exemplary embodiments, the scope of the present patent application is not limited to the disclosed embodiments, but also encompasses combinations of the disclosed embodiments, as well as modifications to the disclosed embodiments as well as other embodiments.

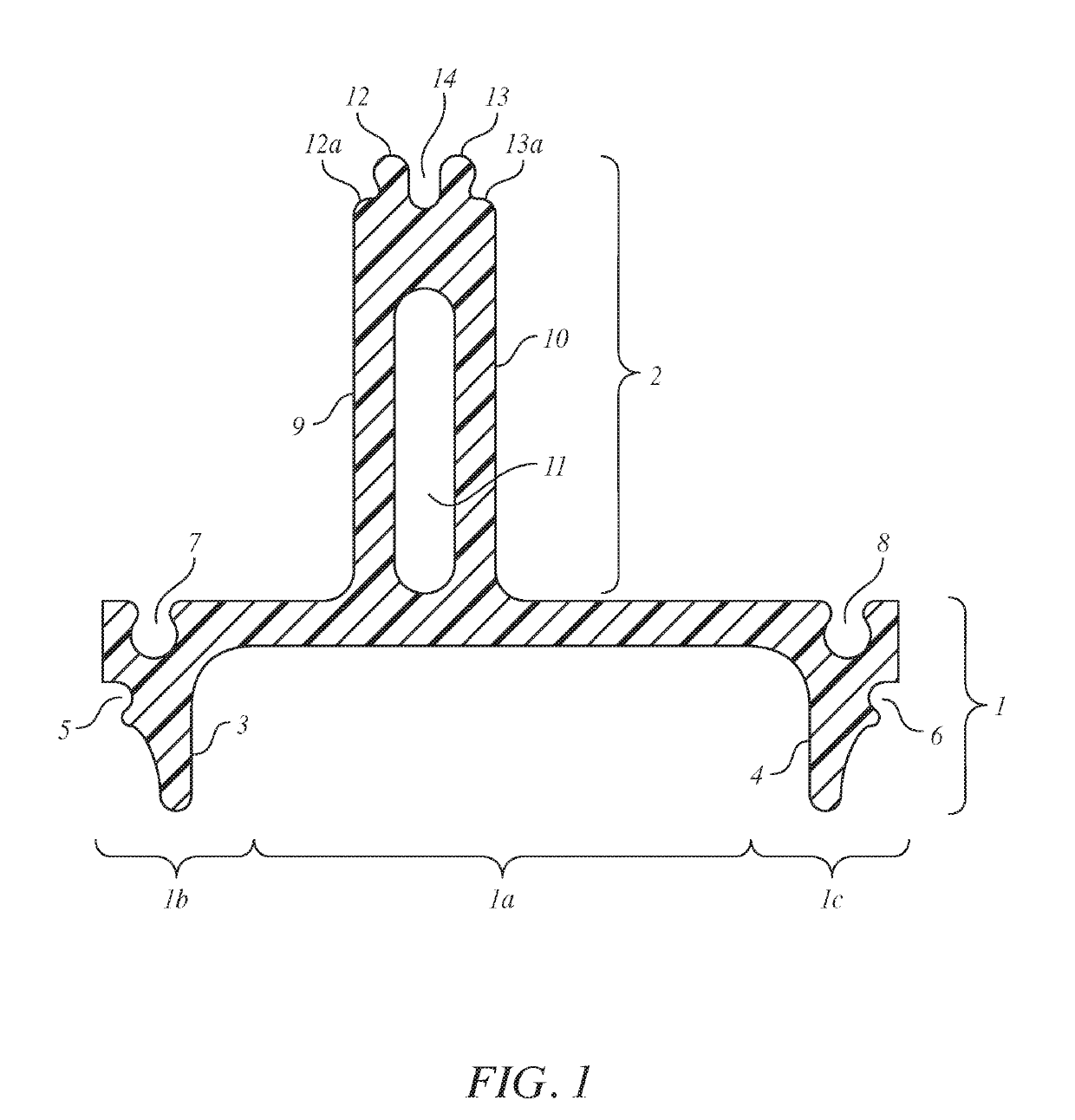

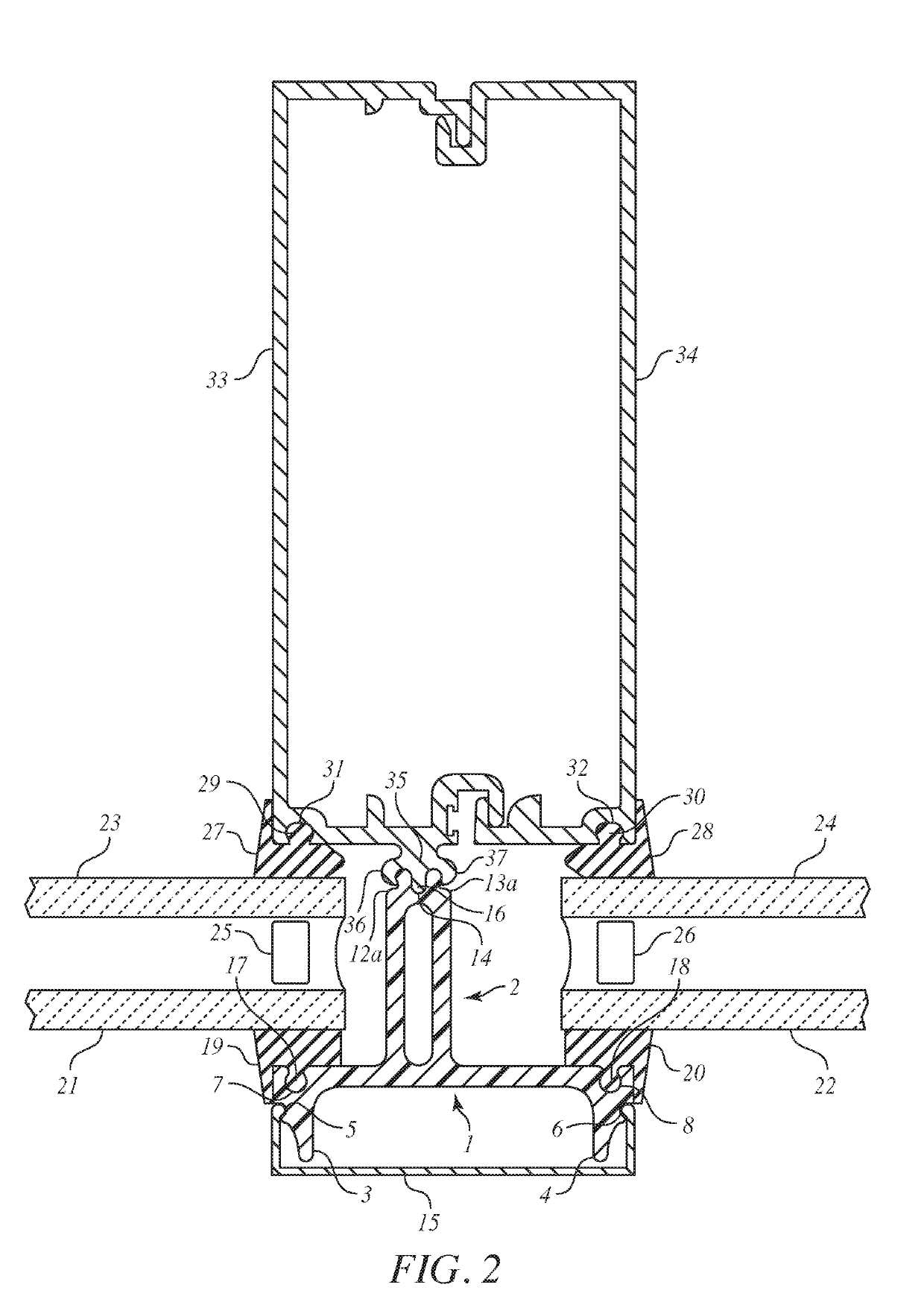

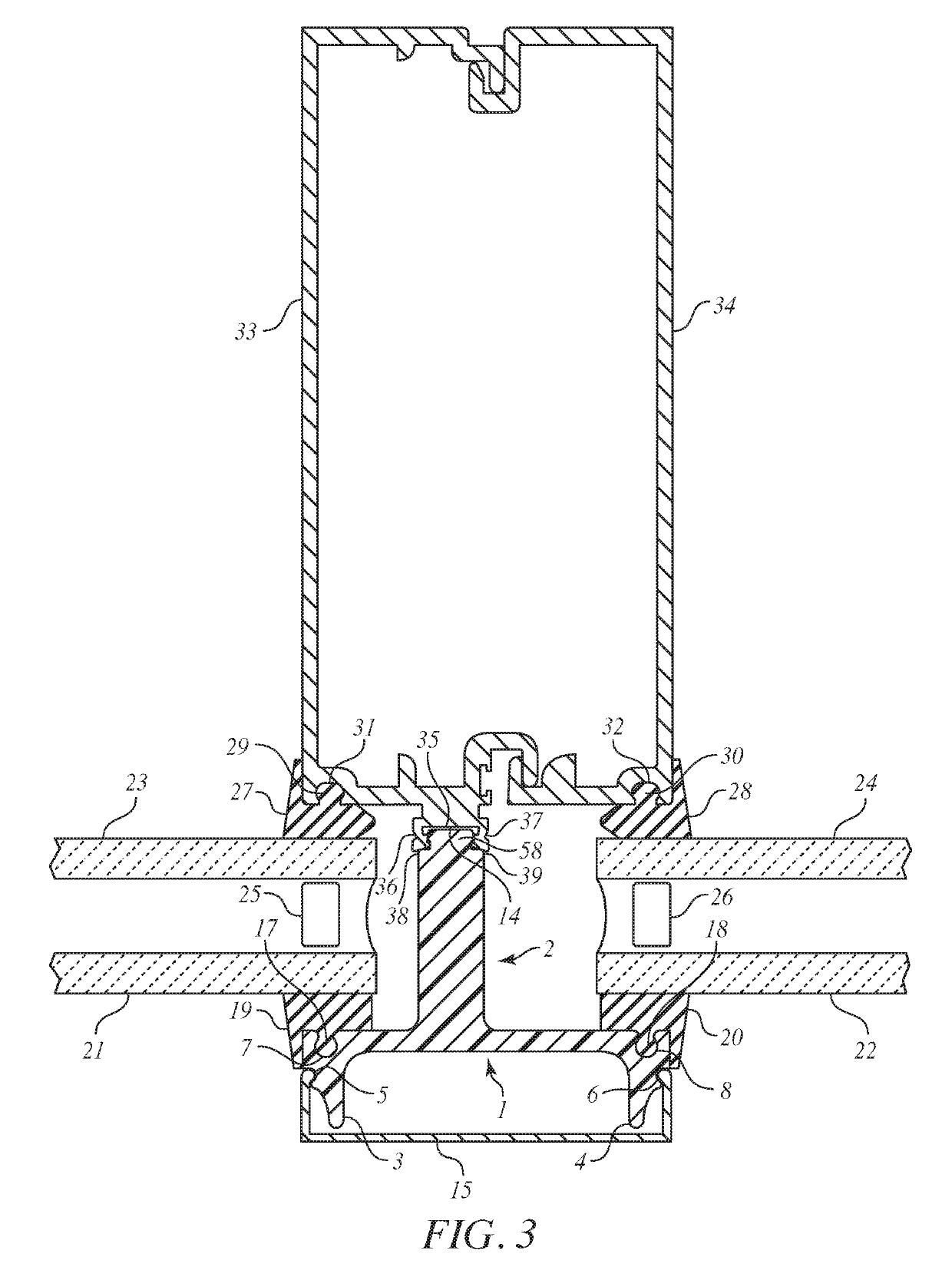

[0026]Within the context of the present invention and as discussed in the background section, thermal break is used to mean a mean a piece of material having a low thermal conductivity that is attached to a member of high conductivity in order to reduce heat transfer.

[0027]In one aspect, the present invention provides a monolithic thermal break structural member. Within the context of the invention, the monolithic thermal break structural member may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com