Foodstuff preparation device and method

a technology for preparing devices and foodstuffs, applied in the field of food preparation devices and methods, can solve the problems of reducing the ability of the eater to perform other activities, reducing the quality of the sandwich, and producing unwanted stains, so as to reduce the chance of grip slippage during operation, improve the user's grip on the device, and improve the effect of the user's grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

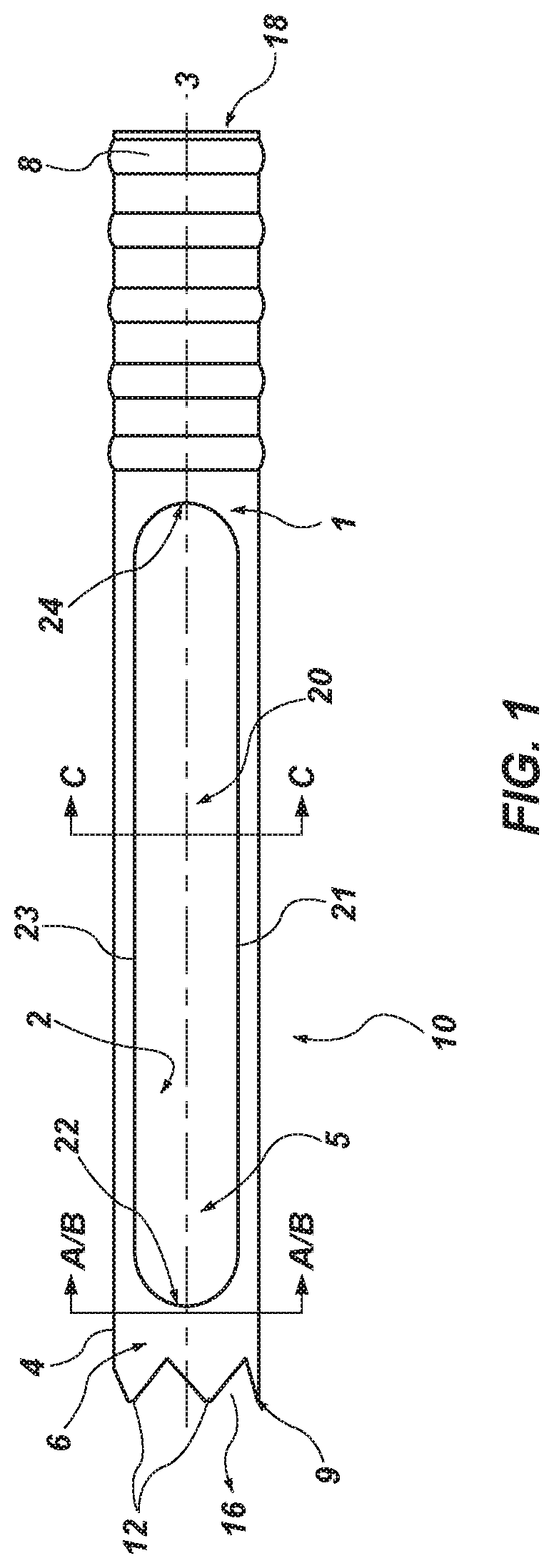

[0035]FIG. 1 shows a foodstuff preparation device 10 in perspective view. The device 10 has a substantially cylindrical wall 4 having a main axis 3. The wall 4 has an outer surface 1 and an inner surface 2. The inner surface 2 defines a cylindrical channel 5 centered around the axis 3. In an embodiment, the channel 5 is a continuous through-channel, having an anterior opening 16 and a posterior opening 18. In an alternative embodiment, the channel 5 is closed at the posterior end 8 of the device 10.

[0036]The wall 4 at the anterior end 6 of the device 10, incorporates a cutting arrangement 9. The cutting arrangement 9 allows the device 10 to cut through the flesh of the baguette, particularly if a twisting motion is applied to the device 10 during the cutting action. In the current embodiment, the cutting arrangement 9 is a series of axially extending cuspate, or saw-tooth, portions 12 continuously formed with and extending from, the wall 4. In an alternative embodiment, the cuspate ...

second embodiment

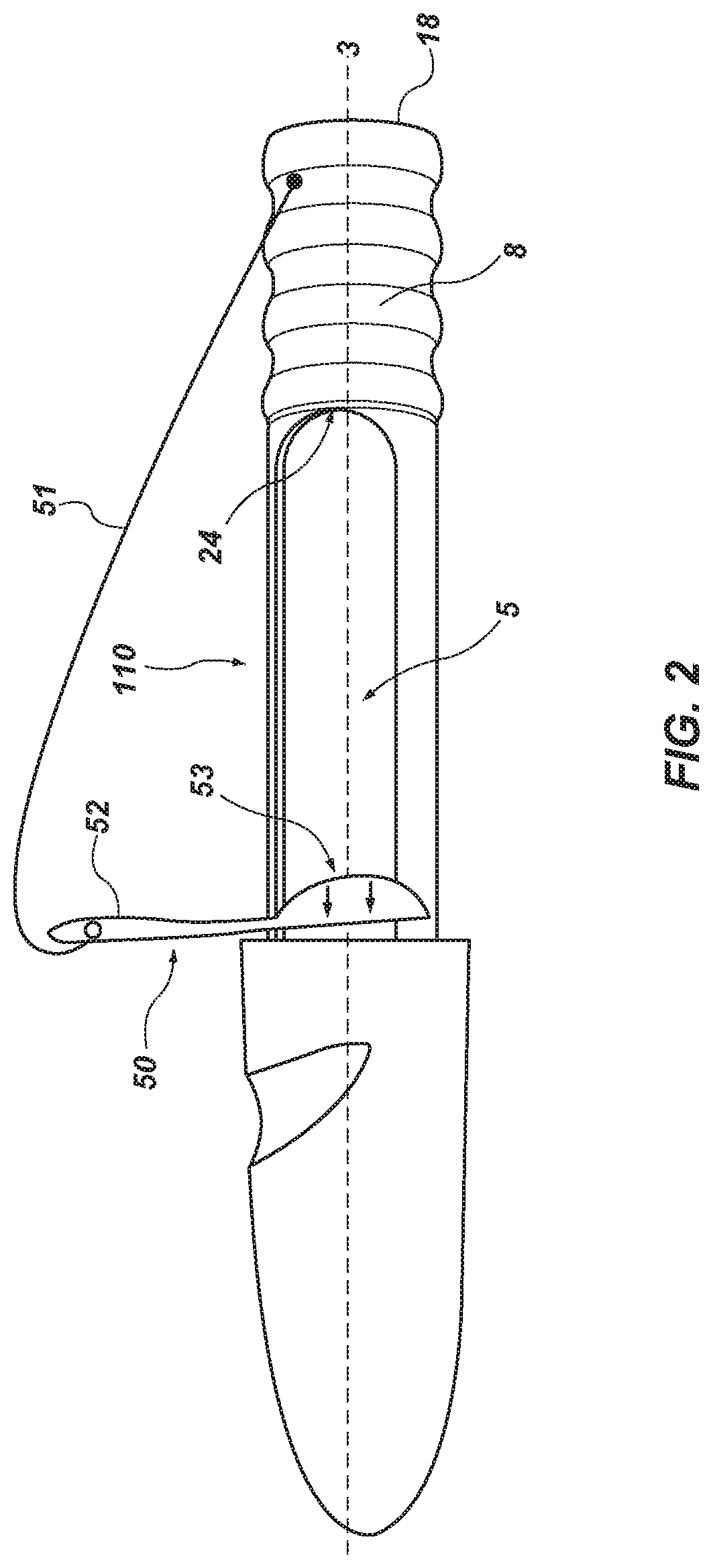

[0040]FIG. 2 shows a foodstuff preparation device 110 in perspective view, in use. The device 110 is shown with positioned such that the anterior end 6 is inserted into a baguette. In the embodiment of FIG. 2, the device 110 includes a tool 50, attached to the device 110. The tool 50 is designed for removing the column of bread, removed from the baguette, from the channel 5 and subsequently for aiding in pushing fillings from the channel 5 into the hollowed baguette. In the illustrated exemplary embodiment, the tool 50 has a handle 52 attached to a head 53. In a preferred embodiment, the head 53 is substantially round, with a radius of curvature substantially equal to that of the inner surface 2 of the wall 4 (see FIG. 1). The diameter of the head 53 is less than the cross-sectional diameter of the channel 5, such that the head 53 can move within the channel 5 along the axis 3. In a preferred embodiment, the head 53 is planar. In an alternative embodiment, the head 53 can be any one...

third embodiment

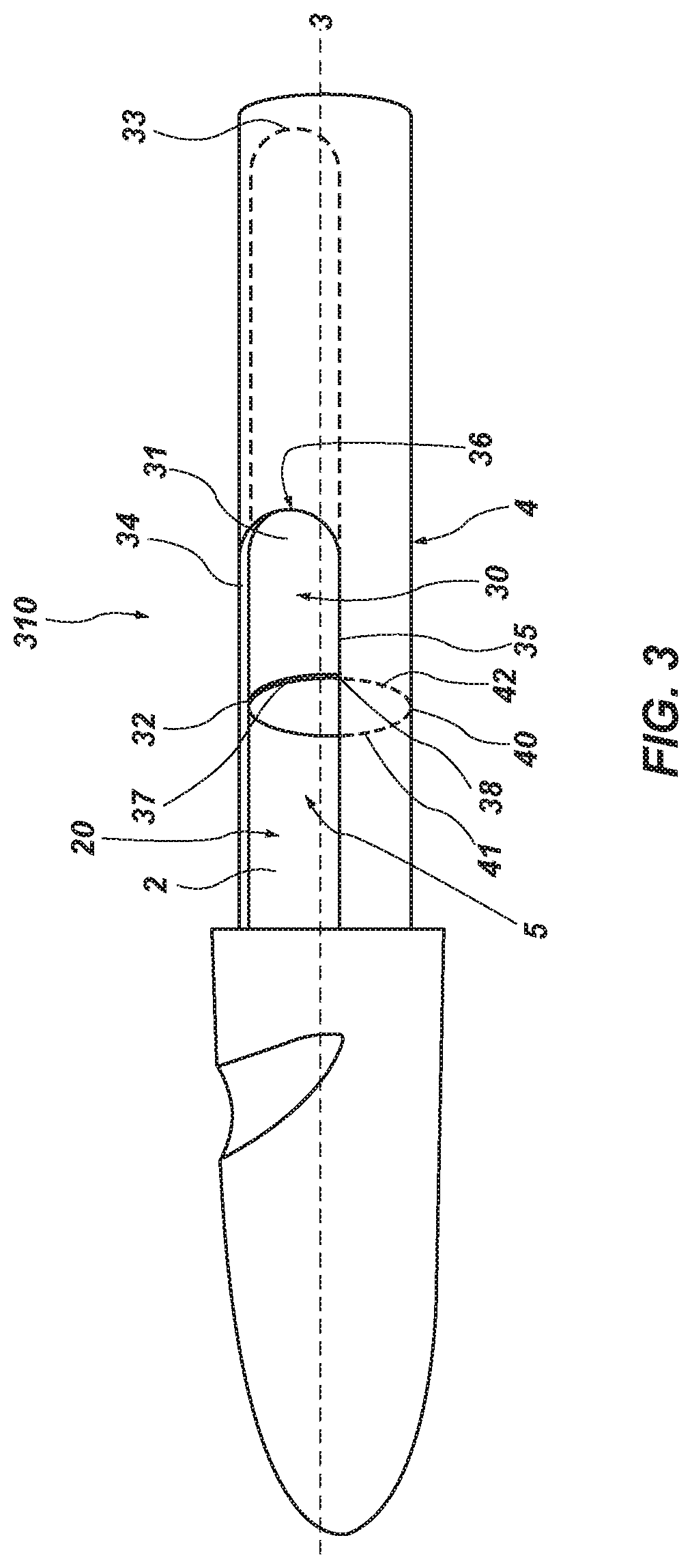

[0041]FIG. 3 shows a foodstuff preparation device 310 in perspective view, in use. The device 310 has an integral cover 30 extending across the internal side of the aperture 20 preventing access to the channel 5. The cover 30 incorporates an arched portion 31, and a flange 32. The arched portion 31 defines a continuous arcuate surface 36, curving from the edge 34 to the edge 35 around the axis 3. The arched portion 31 has a radius of curvature smaller than that of the inner surface 2 of the device 310, such that, in use, the surface of the arched portion 31 is in continuous frictional contact with the inner surface 2 of the wall 4. The linear distance between the edges 34 and 35 of the arched portion 31 is equal to the width of the aperture 20, such that, in a closed configuration, the arched portion 31 completely covers the width of the aperture 20. The distance between the posterior edge 33 of the arched portion 31 and the flange 32 is equal to the distance between first and secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com